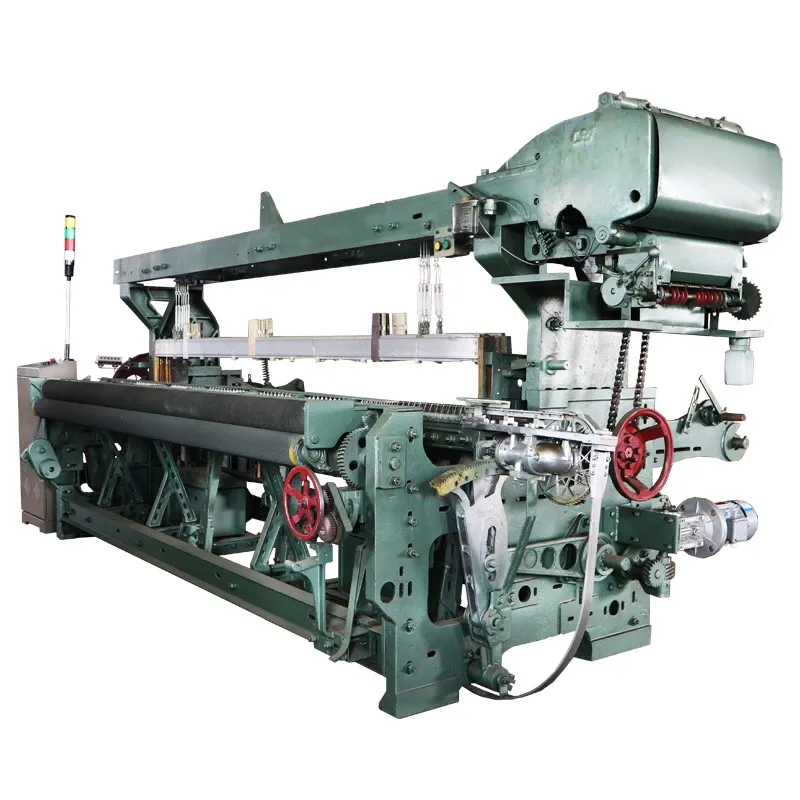

When it comes to manufacturing durable and high-quality window screens, the right window screen machine is indispensable. This specialized equipment is designed to automate the production process, enabling manufacturers to build window screen products efficiently with consistent precision. Whether you are producing fiberglass, aluminum, or stainless steel mesh screens, a reliable window screen machine guarantees superior mesh quality that meets customer expectations.

Сучасны window screen machines feature automated feeding, cutting, and weaving functions, significantly reducing manual labor and production time. They are engineered to handle different mesh materials and sizes, providing versatility for various window screen applications—from residential to commercial use. The advanced control systems incorporated into these machines allow operators to adjust mesh density, tension, and dimensions on the fly, enabling quick shifts between different product specifications.

Choosing the right window screen machine is a strategic investment that improves output quality while minimizing waste and operational costs, allowing manufacturers to scale their businesses with confidence.

How to Build Window Screen with Advanced Window Screen Machines

Building a window screen manually is time-consuming and prone to errors, but with an automated window screen machine, the process becomes streamlined and highly efficient. These machines simplify the critical steps involved in screen production: wire feeding, mesh weaving, cutting, and framing.

The first step in the process is the selection of wire material, often made from fiberglass or aluminum, which is then fed into the machine. The window screen machine tightly weaves the wires into the required mesh size and shape, ensuring a uniform pattern that provides optimal airflow while keeping out insects.

Operators can program the machine to accommodate different mesh dimensions, such as 18x16 or 20x20 mesh counts, according to market demand. After weaving, the machine automatically cuts the mesh to the specified size and prepares it for framing.

Using an automated window screen machine allows manufacturers to consistently build window screen products that meet industry standards for durability, appearance, and functionality.

Wire Drawing Machine Cost: Understanding Your Investment in Quality Wire

Behind every high-quality window screen lies quality wire, and this is where the wire drawing machine cost becomes a critical consideration. Wire drawing machines are used to reduce the diameter of metal wire by pulling it through a series of dies, resulting in wire that is smooth, strong, and perfect for weaving into window screens.

The wire drawing machine cost can vary based on the machine’s capacity, technology, and country of manufacture. Basic wire drawing machines suitable for small-scale wire production might start around $10,000, while advanced models capable of high-speed operation and multiple wire processing lines can exceed $50,000.

Investing in a high-quality wire drawing machine ensures that your wire maintains consistent diameter and surface finish, directly impacting the performance and longevity of the window screens produced. In the long term, this investment reduces wire breakage and wastage during weaving, making the wire drawing machine cost a valuable part of your production chain.

Choosing the Right Window Screen Machine and Wire Drawing Equipment for Your Business

To build window screen products that stand out in the market, it is essential to choose both a reliable window screen machine and efficient wire drawing equipment that complement each other. When selecting a window screen machine, consider the types of mesh materials you will work with, production capacity needs, and machine automation level.

Simultaneously, evaluate the wire drawing machine cost in relation to the wire types and diameters you plan to produce. Opting for machines with energy-efficient motors, automated controls, and durable construction will maximize your return on investment.

It’s also important to partner with manufacturers or suppliers who provide strong after-sales support, including installation, training, and spare parts availability. This support minimizes downtime and ensures your production lines operate smoothly.

By investing wisely in both window screen machine and wire drawing equipment, your business can achieve consistent quality, reduce operational costs, and meet growing market demands.

Where to Find High-Quality Window Screen Machines and Wire Drawing Machines

High-quality window screen machines and wire drawing equipment are available from manufacturers worldwide, with China, Germany, and Italy leading in industrial machinery innovation. Many suppliers offer customizable solutions that allow businesses to tailor machines to specific production needs.

Online B2B platforms such as Alibaba, Made-in-China, and Globalsources provide extensive catalogs where you can compare features, pricing, and supplier reputations for window screen machines and wire drawing machines. Many suppliers also provide videos demonstrating machine operation, which helps in assessing build quality and ease of use.

When purchasing machinery, ensure suppliers have proper certifications (ISO, CE) and a proven track record. Attending industry exhibitions is another great way to meet window screen machine manufacturers and inspect their equipment firsthand.

In addition, sourcing from reputable manufacturers who offer comprehensive warranties and robust technical support will secure your investment and enhance production reliability.

FAQs About Window Screen Machines

What materials can a window screen machine handle?

Window screen machines typically handle fiberglass, aluminum, stainless steel, and sometimes copper wire. Each material requires specific tension and weaving settings, which modern machines can accommodate.

How does wire drawing improve wire quality for window screens?

Wire drawing reduces the diameter and enhances the surface finish of metal wires, making them smoother, stronger, and more uniform. This process prevents wire breakage during weaving and improves the final screen durability.

What factors influence the wire drawing machine cost?

The cost depends on machine capacity (wire speed and diameter range), automation level, build quality, and country of manufacture. Higher-end machines with multiple wire lines and advanced controls are priced higher but offer better efficiency.

Can I switch mesh sizes easily on a window screen machine?

Yes, most modern window screen machines allow operators to adjust mesh size, tension, and wire feed rate quickly, enabling flexible production of various screen specifications.

What maintenance does a window screen machine require?

Regular maintenance includes lubricating moving parts, checking wire tension and guides, cleaning sensors and cutters, and inspecting electrical components. Following manufacturer guidelines ensures optimal performance.