As global construction, agriculture, and fencing industries grow, so does the demand for durable and efficient wire mesh. If you're looking to boost your productivity and scale your operations, investing in a wire mesh machine for sale is a strategic move that delivers long-term returns.

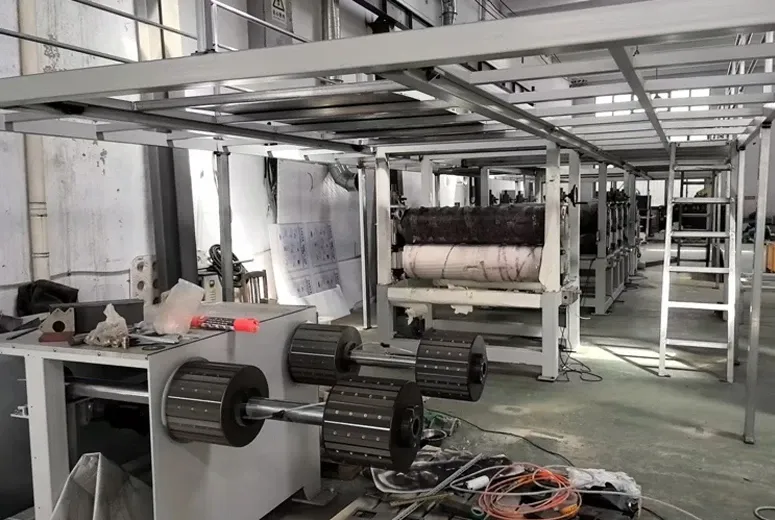

Modern wire mesh machines for sale are not just about speed—they're about consistency, automation, and versatility. Whether you need a machine for heavy-duty welded mesh panels or light chain-link fencing, today’s equipment is designed to meet industrial-grade standards with minimal labor input.

Choosing a wire mesh machine for sale means considering various factors such as production capacity, mesh dimensions, material compatibility, and ease of maintenance. Most high-end machines come with programmable controls, touch-screen interfaces, and automatic feeding and cutting systems.

Leading global manufacturers and suppliers now offer detailed catalogs featuring each wire mesh machine for sale, along with specifications and optional add-ons. These listings often include demo videos, technical sheets, and customer feedback—helping buyers make well-informed decisions with complete transparency.

Whether you're a seasoned industry player or a startup manufacturer, the right wire mesh machine for sale will elevate your business by ensuring precision, reducing waste, and scaling output.

Wire Mesh Making Machine: Innovation Behind Every Grid

The backbone of any successful wire product operation lies in a high-performance machine de fabrication de treillis métallique. These machines automate the complex task of mesh formation—whether through welding, weaving, or crimping—enabling manufacturers to meet high-volume orders without compromising quality.

Today’s wire mesh making machines are engineered for flexibility. Some can be programmed for different mesh dimensions and wire gauges, offering a dynamic production solution. Whether you're producing mesh for concrete reinforcement, security fencing, or industrial filters, there’s a dedicated machine that caters to that specification.

Automation is central to every modern machine de fabrication de treillis métallique. PLC control systems, servo motors, and intelligent diagnostics are standard in top-tier models. These systems optimize speed and precision while minimizing human intervention, reducing labor costs and error rates.

Additionally, many manufacturers are integrating smart features like remote diagnostics and data logging into their wire mesh making machines, helping operators monitor productivity in real-time and plan preventive maintenance schedules effectively.

As industry demand grows for customization and speed, having a cutting-edge machine de fabrication de treillis métallique is no longer optional—it’s essential.

Wire Net Making Machine Price: Factors That Matter

Comprendre le prix de la machine de fabrication de grillage is key to making a sound investment. While pricing can vary significantly, the cost is typically based on machine type, production capacity, automation level, and included accessories.

For instance, a semi-automatic machine de fabrication de grillage that produces standard chain-link fences might start at $5,000 to $10,000. In contrast, a high-speed, fully automated welded mesh machine with a programmable control panel could range from $20,000 to $100,000 or more, depending on size and customization.

Another element that influences the prix de la machine de fabrication de grillage is the wire material compatibility. Machines that handle stainless steel, galvanized iron, or PVC-coated wire may require specific adjustments or high-torque feeding systems, which increase cost.

It’s also important to factor in post-sale services such as installation, training, and maintenance when evaluating the total cost of ownership. A slightly higher prix de la machine de fabrication de grillage from a reputable supplier may ultimately save you thousands in downtime, replacement parts, and lost productivity.

When comparing prices, always ask for a detailed quotation including machine configuration, warranty terms, delivery lead time, and after-sales support. A transparent prix de la machine de fabrication de grillage from a trusted supplier ensures you avoid hidden costs and production delays.

Wire Mesh Machine Video: See the Machine in Action

In an age where virtual demonstrations have become standard, watching a wire mesh machine video can offer valuable insight before making a purchase. These videos give prospective buyers a visual understanding of how the machine operates, the production speed, product quality, and the ease of use.

A detailed wire mesh machine video typically includes a full run of the equipment—from wire feeding and straightening to mesh forming, cutting, and stacking. High-resolution clips show the finesse of the welding joints, mesh uniformity, and interface navigation. You’ll also see how long it takes to complete each cycle and how operators interact with the system.

Some suppliers even offer custom demo videos upon request. If you’re interested in specific mesh types or wire materials, they can create tailored footage demonstrating machine compatibility. These videos often include captions or voiceover explanations that highlight key features.

Watching a wire mesh machine video not only helps with machine selection but can also assist your team in understanding future operation and maintenance procedures. It sets realistic expectations and provides early exposure to the workflow, reducing your post-installation learning curve.

Whether embedded in product listings or shared during a sales consultation, a good wire mesh machine video is an essential part of the decision-making process.

Choosing the Right Wire Mesh Machine for Your Production Needs

Not all wire mesh machines are created equal. The right machine for your business depends on several production variables: mesh type, wire material, desired output, and available space. Whether you need a general-purpose machine de fabrication de treillis métallique or a specialized system for architectural mesh, choosing the right equipment ensures operational efficiency and long-term scalability.

For construction reinforcement, a heavy-duty welded mesh machine is ideal. These systems are designed for thicker wire gauges and can weld large panels at high speeds. For fencing, a chain-link machine or hexagonal wire netting machine may be more suitable, offering adjustable mesh openings and wire twists.

If your products require high precision and aesthetics—such as speaker grilles or decorative facades—an expanded metal mesh machine might be your best bet. These machines punch and stretch metal sheets into uniform mesh patterns and are commonly used in architectural and industrial design.

Buyers should also consider the wire feed system, energy consumption, and maintenance cycle of the equipment. While a basic machine may seem attractive due to a lower prix de la machine de fabrication de grillage, it may lack the durability or flexibility needed for long-term success.

Consulting detailed catalogs, watching a wire mesh machine video, and talking directly with sales engineers can help you narrow your choices to the best fit. The right decision now leads to years of uninterrupted, high-quality production.

FAQs About Wire Mesh Machines

What is the average lifespan of a wire mesh machine?

A high-quality wire mesh machine, with regular maintenance and proper use, can last 10 to 15 years or more. The lifespan depends on the machine type, production volume, and adherence to manufacturer-recommended service schedules.

Can wire mesh machines be customized for specific mesh dimensions?

Yes. Most modern wire mesh making machines allow customization for mesh width, length, and aperture size. Machines with PLC systems can be programmed to change settings quickly, allowing operators to shift between production runs with minimal downtime.

Where can I find a good wire mesh machine video?

You can find wire mesh machine videos on supplier websites, YouTube, Alibaba, or B2B platforms like Made-in-China.com and Globalsources.com. Some manufacturers also provide demo videos via email or virtual tours upon request.

How do I know if a wire net making machine price is fair?

Compare multiple quotes from different suppliers, review machine specifications, and check for certifications like CE or ISO. Also, inquire about after-sales service, training, and warranty—often, a higher initial cost can result in lower long-term expenses.

Do wire mesh machines require a lot of training to operate?

Basic operation of a wire mesh machine is relatively straightforward, especially with PLC interfaces. However, for more complex machines, manufacturers often provide operator training during installation. Some also offer instructional manuals, videos, and remote support.

Perméable

Suivant