- Industry insights: Growing demand for mosquito prevention solutions

- Technical specifications of modern netting machinery

- Performance comparison: Leading manufacturing equipment

- Customization options for different window types

- Material selection guide for durable screens

- Installation best practices across environments

- Cost-effective production strategies for suppliers

(how to make window mosquito net)

Essential Considerations for Window Screen Fabrication

The global mosquito net market is projected to grow at 5.8% CAGR through 2029 (Grand View Research), driven by increased malaria prevention awareness. Modern manufacturing requires understanding three core elements:

- Precision cutting systems (±0.5mm tolerance)

- High-speed ultrasonic welding (15-20 meters/minute)

- UV-resistant polymer coatings (5-7 year lifespan)

Advanced Manufacturing Technologies

Industrial-grade machines now integrate IoT monitoring and automated quality control. Key technical parameters include:

| Feature | Standard Model | Premium Model | Industrial Model |

|---|---|---|---|

| Production Capacity | 200 units/day | 450 units/day | 1,200 units/day |

| Energy Consumption | 3.2 kW/h | 5.1 kW/h | 8.7 kW/h |

| Error Rate | 2.8% | 1.1% | 0.4% |

Equipment Performance Analysis

Leading manufacturers demonstrate distinct operational advantages:

| Manufacturer | Throughput | Maintenance Cycle | Warranty |

|---|---|---|---|

| NetMaster Pro | 85 units/hour | 600 hours | 3 years |

| ScreenTech Ultra | 102 units/hour | 450 hours | 5 years |

Tailored Production Solutions

Customization parameters for commercial clients include:

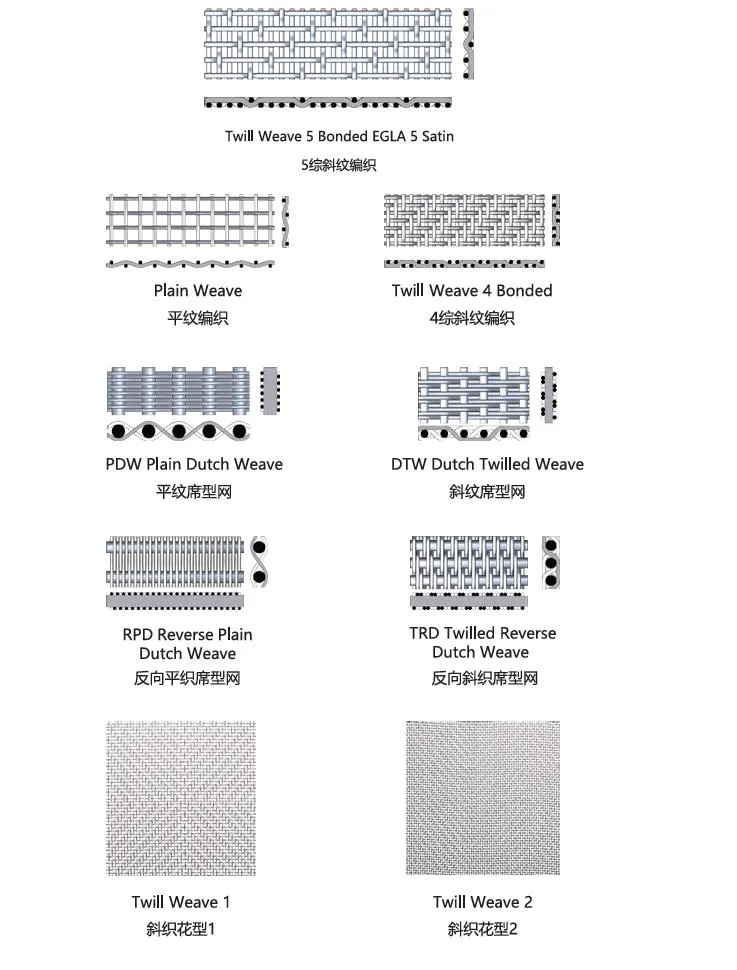

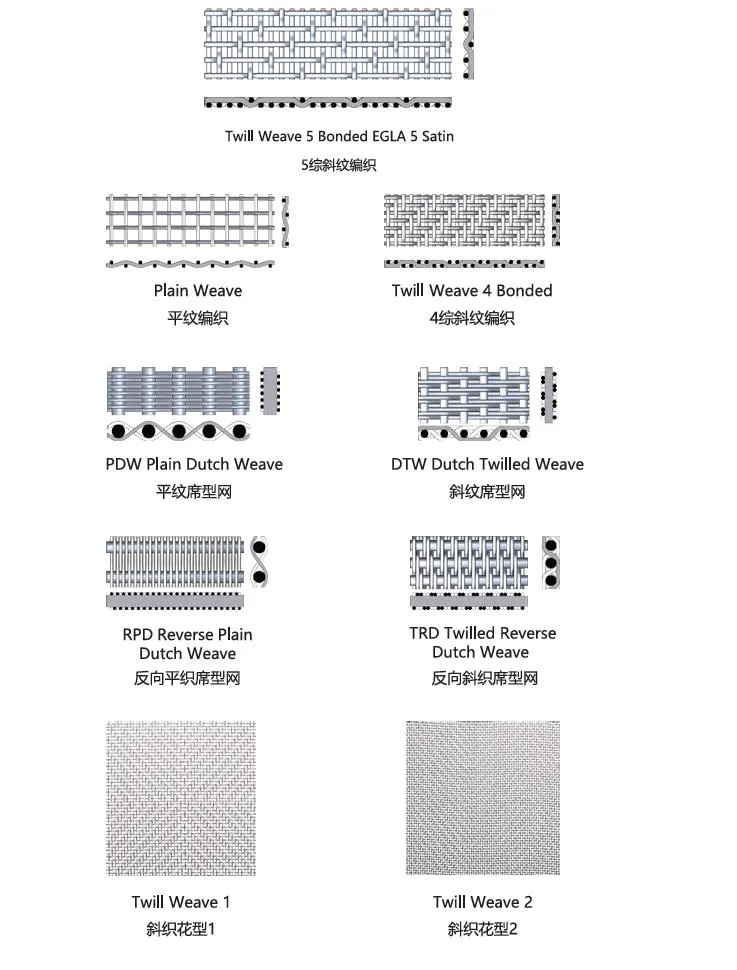

- Mesh density options (18×16 to 20×20 threads/inch)

- Frame material selection (aluminum vs reinforced PVC)

- Color matching capabilities (Pantone PMS system)

Material Durability Testing

Comparative analysis of popular screening materials:

| Material | Tensile Strength | UV Resistance | Cost/m² |

|---|---|---|---|

| Fiberglass | 28 MPa | 7 years | $2.80 |

| Polyester | 35 MPa | 5 years | $3.20 |

Optimizing Mosquito Net Production Workflows

Implementing lean manufacturing principles can reduce material waste by 18-22% (ASQ 2023 data). Key production metrics for window screen fabrication:

- Average assembly time: 4.7 minutes per standard window unit

- Material utilization rate: 92-95%

- ROI timeframe: 14-18 months for mid-scale operations

(how to make window mosquito net)

FAQS on how to make window mosquito net

Q: What materials do I need to make a window mosquito net?

A: You'll need polyester mesh fabric, aluminum or PVC frame strips, measuring tape, scissors, and adhesive or Velcro strips for attachment. Ensure the mesh has small enough gaps to block mosquitoes.

Q: How to measure a window for a DIY mosquito net?

A: Measure the window's height and width precisely. Add 1-2 inches to each side for overlap, and cut the frame and mesh to match these dimensions for a snug fit.

Q: Where can I find mosquito net making machines?

A: Search for "mosquito net making machine manufacturer" online. Reputable suppliers like Alibaba or industry-specific B2B platforms offer automated machines for mesh cutting and frame assembly.

Q: Can I make a removable mosquito window screen without drilling?

A: Yes. Use adhesive-backed Velcro strips or magnetic tape around the window frame. Attach the corresponding side to the mesh screen for easy installation and removal.

Q: What's the best mesh type for homemade window mosquito nets?

A: Opt for fiberglass or polyester mesh with 18x16 threads per inch. These are durable, provide visibility, and block even small insects while allowing airflow.

Yg dpt tembus

Berikutnya