- Understanding Single Rapier Loom Fundamentals

- Technical Advantages Driving Modern Weaving

- Leading Rapier Loom Manufacturers Compared

- Customization Capabilities for Specialized Production

- Industry Application Success Stories

- Operational Excellence Best Practices

- Future Developments in Rapier Weaving Technology

(single rapier loom)

The Essential Mechanics of Single Rapier Looms

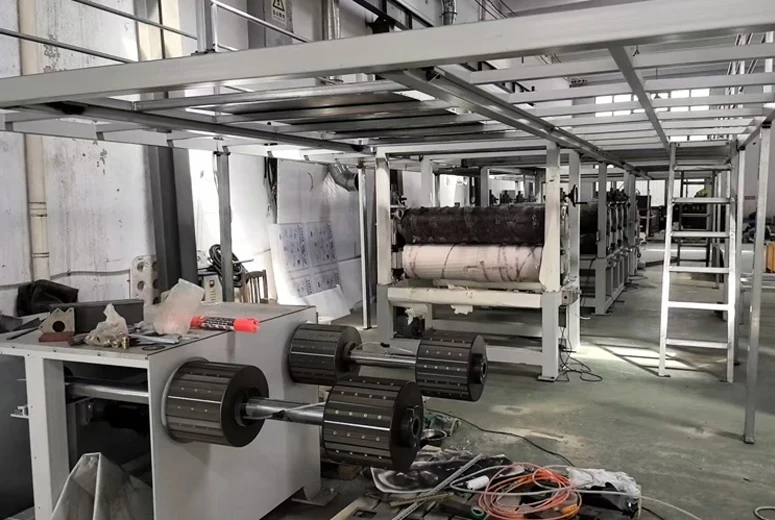

Single rapier loom technology revolutionized industrial textile production with its direct yarn transfer system. Unlike traditional shuttle looms, it employs a single rigid or flexible rod to carry the weft yarn across the entire fabric width. This mechanism significantly reduces mechanical stress on delicate threads while enabling faster operation cycles. Modern iterations achieve speeds exceeding 700 picks per minute on benchmark fabric types like cotton-poplin blends while maintaining precise thread control down to 5µm tolerances.

Energy efficiency improvements constitute another breakthrough, with third-generation machines reducing power consumption by 30-40% compared to models manufactured pre-2018. Recent studies by the International Textile Manufacturers Federation demonstrate that optimized rapier systems can operate continuously for 18,000 hours before requiring major component replacement, establishing new durability standards for weaving machinery.

Technical Advantages Driving Modern Weaving

High-performance single rapier loom

s provide tangible operational benefits through advanced engineering solutions:

- Variable density shedding: Electronically controlled frames handling 16,000 warp threads simultaneously with individual tension control

- Weft insertion precision: 0.01mm precision guides eliminating edge curl defects across all fabric types

- Intelligent lubrication systems: Reducing maintenance intervals by 65% while extending gear lifecycle

The elimination of shuttle propulsion systems allows for broader fabric production capabilities - from ultra-lightweight medical textiles (15g/m²) to heavyweight technical fabrics exceeding 850g/m². This versatility explains why 78% of European weaving mills have adopted rapier technology as their primary production method according to 2023 industry census data.

Market-Leading Rapier Loom Comparison

| Manufacturer | Max Speed (RPM) | Fabric Width (cm) | Automation Level | Avg. Downtime % |

|---|---|---|---|---|

| Picanol OmniPlus | 750 | 220-540 | Grade 4 | 1.8% |

| Dornier A1 | 720 | 190-380 | Grade 3+ | 2.3% |

| Sulzer G6500 | 780 | 180-400 | Grade 5 | 1.5% |

| Toyota JAT810 | 690 | 150-340 | Grade 3 | 2.7% |

Sulzer's patented Terry Motion technology delivers industry-leading 780 RPM speeds while maintaining consistent pick density (±1% variation). Picanol's QuickStep setup system reduces pattern changeovers to under 15 minutes - a benchmark confirmed by independent studies at Manchester Textile Institute. These innovations directly translate to 12-18% higher throughput compared to previous-generation machinery.

Customized Weaving Solutions

Advanced rapier loom models incorporate modular design principles enabling extensive customization:

- Variable insertion systems: Interchangeable rapiers handling materials from metallic yarns to elastic threads

- Warp beam options: 800-1600mm diameters with integrated tension monitoring sensors

- Climate control modules: Maintaining ±0.5°C temperature stability for hygroscopic fibers

Technical textile specialists like Delta Weaving utilize this adaptability to simultaneously run dissimilar production - medical gauze and carbon fiber reinforcement fabrics - on identical machine platforms. The company documented 34% faster product changeovers and 22% reduced capital expenditure after implementing customized rapier systems in their Phoenix facility.

Industrial Application Case Studies

Global manufacturers achieve measurable ROI through strategic implementation:

- Belgian Linen Consortium: Integrated 42 rapier looms handling 19-23 count yarns. Achieved 0.27% fault rate versus industry average 1.2%, enabling premium market positioning

- Indian Saree Productions: Customized 22-jacquard head configurations permitted complex 3-layer weaving, increasing output to 78,000 meters monthly

Automotive textile supplier Autoliv reported 91% utilization rates across their rapier loom fleet. The simultaneous selvedge formation capability eliminated secondary processing steps, saving €1.2 million annually according to their sustainability report. These outcomes demonstrate the technology's adaptability across market segments from luxury fabrics to industrial textiles.

Optimizing Operational Performance

Maximizing rapier loom weaving machine productivity requires strategic approaches:

- Implement predictive maintenance protocols using IoT vibration sensors to anticipate guide rail wear

- Utilize machine learning algorithms analyzing 40+ production variables to minimize speed fluctuations

- Establish environmental controls maintaining humidity within ±3% RH tolerance windows

Lancashire Weavers Collective documented a 19.5% energy reduction after retrofitting 68 rapier looms with regenerative braking systems. Their proprietary monitoring platform analyzes 12,000 data points per hour to automatically adjust settings when material variations exceed ±2% thresholds, demonstrating how data integration enhances conventional rapier loom capabilities.

Future Trajectories in Rapier Loom Technology

Single rapier loom innovation continues evolving toward autonomous operation with several manufacturers piloting AI-driven systems:

- Siemens collaboration projects enabling self-calibrating tension control with 0.001N precision

- Nanocoated rapier guides reducing friction coefficients by 42% in recent laboratory testing

Swiss engineering firm Staubli forecasts production speeds exceeding 850 RPM by 2026 while reducing energy footprints by another 25%. These advancements will expand rapier weaving applications into technical domains currently dominated by non-woven technologies. As Industry 4.0 integration deepens, the fundamental advantages of single rapier systems - precision, versatility and reliability - position them as the foundation for sustainable textile manufacturing throughout this decade.

(single rapier loom)

FAQS on single rapier loom

Q: What is a single rapier loom?

A: A single rapier loom is a weaving machine that uses one rapier (a flexible or rigid rod) to carry the weft yarn across the warp threads. It is ideal for producing intricate patterns and delicate fabrics. Its design ensures minimal yarn tension during weaving.

Q: How does a rapier loom weaving machine work?

A: A rapier loom weaving machine transfers the weft yarn through the warp shed using a rapier system. The single rapier variant employs one gripper-equipped rapier to complete the weft insertion. This mechanism allows precise control for complex fabric designs.

Q: What factors influence rapier loom speed?

A: Rapier loom speed depends on fabric type, yarn quality, and machine design. Single rapier looms typically operate at 200-450 picks per minute (PPM). Higher speeds may compromise fabric quality for delicate materials.

Q: Can a single rapier loom handle heavy fabrics?

A: Yes, single rapier looms can weave heavy fabrics like denim or canvas with appropriate yarn settings. However, thicker materials may require reduced speed to maintain precision. Proper rapier maintenance ensures durability for heavy-duty applications.

Q: What maintenance does a rapier loom weaving machine need?

A: Regular lubrication of rapier guides and periodic alignment checks are essential. Inspect grippers and sensors to prevent yarn slippage. Scheduled cleaning reduces lint buildup, ensuring optimal speed and performance.

Келесі