- Introduction to the Prepreg Machine Market: Innovations and Growth Drivers

- Technological Advancements Elevating Prepreg Machine Performance

- Comparative Analysis of Leading Prepreg Machine Manufacturers

- Customization Capabilities: Adapting Prepreg Machines to Industry Demands

- Real-World Application Examples: Prepreg Machines in Action

- Market Statistics and Future Outlook for Prepreg Machines

- Conclusion: Navigating the Dynamic Prepreg Machine Market

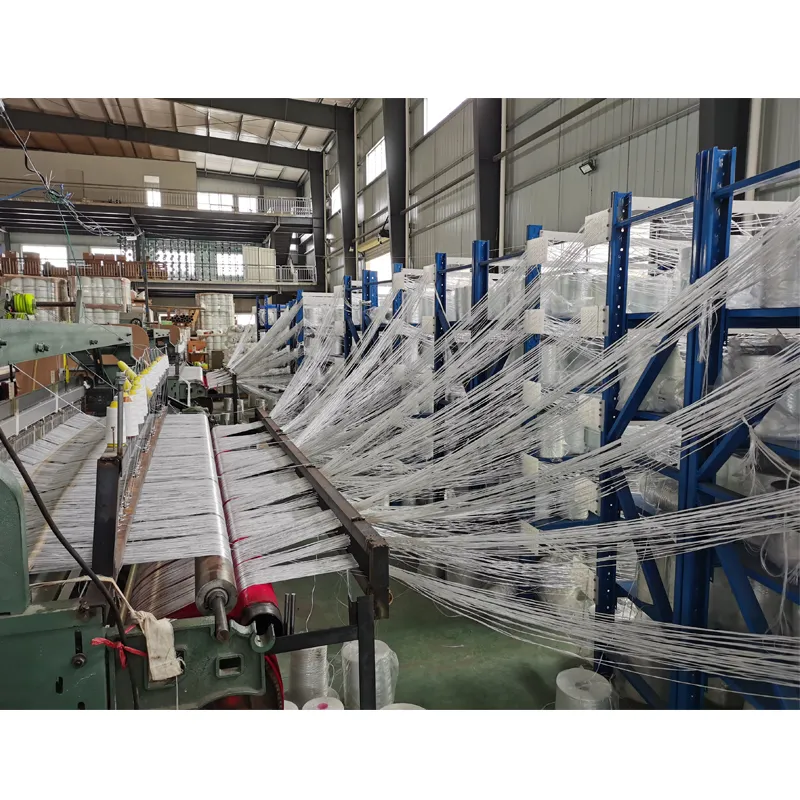

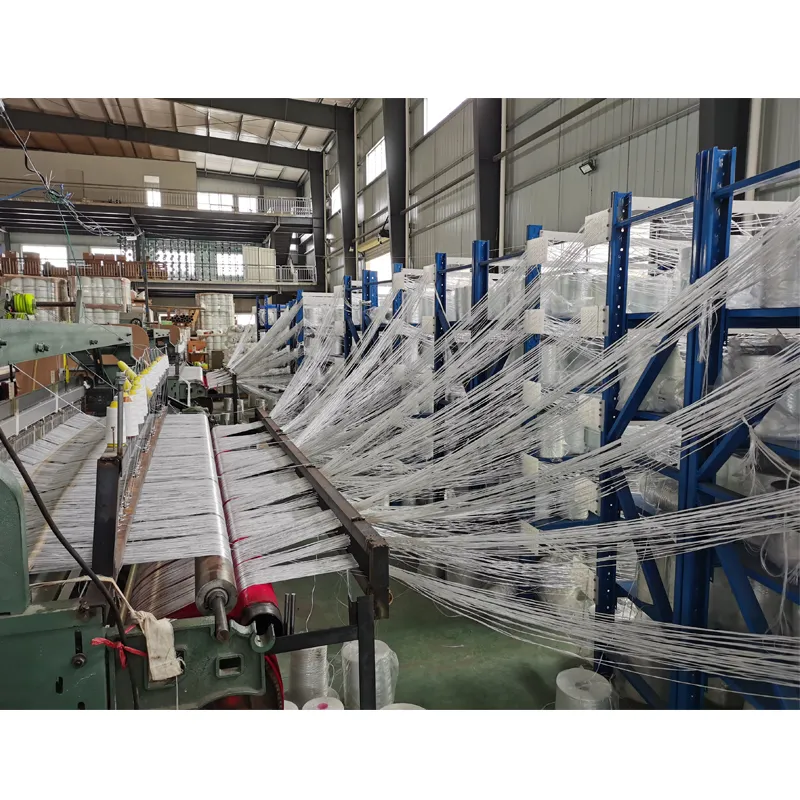

(prepreg machine)

Introduction to the Prepreg Machine Market: Innovations and Growth Drivers

The prepreg machine

industry stands at the forefront of advanced composite manufacturing, acting as a catalyst for industries such as aerospace, automotive, and renewable energy. Evolving market dynamics have ushered in a new era of technological innovation, focused not only on efficiency but also on sustainability and scalability. According to the latest market research, the global prepreg machine market was valued at USD 845 million in 2023, with projections estimating it will expand at a CAGR of 7.1% through 2030, fueled by the rising adoption across high-value manufacturing sectors. This evolving landscape is marked by heightened demand for automated solutions, customization capabilities, and reduced production cycle times, positioning prepreg machines as vital assets in the next generation of industrial technologies.

Technological Advancements Elevating Prepreg Machine Performance

Driven by high-value industry applications, prepreg machines have transitioned from manual systems to intelligent, integrated solutions. Automation is one of the most significant evolutions, reducing human intervention and enhancing product consistency. Modern systems now boast precise resin impregnation technology, IoT connectivity for real-time monitoring, advanced temperature and pressure control, and self-correcting algorithms to minimize material wastage. These features enable manufacturers to achieve tighter tolerances, higher throughput, and improved repeatability. Moreover, recent breakthroughs in eco-friendly resin processing and energy-efficient heating elements have contributed to broader industry acceptance, particularly in sectors targeting lightweighting and reduced environmental impact.

Comparative Analysis of Leading Prepreg Machine Manufacturers

Selecting an optimal prepreg machine solution requires careful consideration of manufacturer capabilities and technology portfolios. The table below presents a comparative overview of three prominent manufacturers in the global market, highlighting factors such as machine capacity, automation level, energy efficiency, warranty, and after-sales service — all critical for investment decisions.

| Manufacturer | Annual Output Capacity (tons) | Automation Grade | Energy Consumption (kWh/ton) | Warranty (Years) | Global After-sales Support |

|---|---|---|---|---|---|

| CompoTech Systems | 1800 | Fully Automatic | 780 | 3 | Yes |

| Laminex Industrial | 1200 | Semi-Automatic | 925 | 2 | Selected Regions |

| FiberMate Technologies | 1600 | Fully Automatic | 835 | 4 | Yes |

From the data, CompoTech Systems leads in annual output and low energy consumption, making it ideal for large-scale operations. FiberMate Technologies offers the longest warranty and comprehensive global support, appealing to organizations with global footprints. Meanwhile, Laminex Industrial presents a cost-effective choice for mid-scale manufacturers focused on regional markets.

Customization Capabilities: Adapting Prepreg Machines to Industry Demands

As diversified material requirements and application specifications proliferate, the ability to customize prepreg machines has become critical for users aiming to remain competitive. Manufacturers increasingly offer modular solutions that can be tailored to accommodate various fiber types (carbon, glass, aramid), resin systems (epoxy, phenolic, BMI), and line widths. Other customization features include adjustable unwinding/rewinding tension controls, flexible heating zones, and data-driven production monitoring interfaces. By leveraging modular hardware and adaptive control software, clients can specify configurations aligned to unique project demands, ensuring both operational flexibility and long-term value. For sectors such as automotive, where rapid model updates are common, customized systems guarantee both responsiveness and future-proof investment.

Real-World Application Examples: Prepreg Machines in Action

The versatility of modern prepreg machines is exemplified across multiple high-performance industries. In aerospace, tailored prepreg lines support demand for lightweight primary structures, facilitating fuel efficiency and performance targets. For example, a leading aircraft producer increased overall productivity by 24% after integrating a high-speed, fully automated prepreg system capable of operating 24/7 with minimal downtime. In wind energy, prepreg machines are used to produce optimized blade laminates, extending turbine lifespans by over 30%. The automotive industry benefits from quick-change resin delivery systems supporting a variety of composite components, reducing cycle times by approximately 18%. Consumer electronics also employs compact prepreg units for advanced sporting goods and electronic enclosures, highlighting the adaptability of this technology to both high-volume and niche production environments.

Market Statistics and Future Outlook for Prepreg Machines

According to a 2023 industry survey, more than 68% of composite manufacturers plan to upgrade or expand prepreg machine installations within the next three years, citing automation and process reliability as top decision factors. Geographic analysis indicates that North America and Asia-Pacific collectively account for over 61% of prepreg machinery investments, with Asia-Pacific demonstrating a compound annual growth rate exceeding 9% due to expanding aerospace and electric vehicle manufacturing ecosystems. By 2030, next-generation prepreg solutions are anticipated to reduce operational energy consumption by 18% and greenhouse gas emissions by up to 15% per unit of output. Expectations for material versatility, digital integration, predictive maintenance, and end-to-end process automation are set to define purchasing criteria, influencing product development cycles and manufacturer partnerships.

Conclusion: Navigating the Dynamic Prepreg Machine Market

The global prepreg machine market is evolving rapidly, fueled by the confluence of technological innovation, diverse industry applications, and growing environmental concerns. Companies evaluating investments in new prepreg machinery face a landscape shaped by high-performance standards, competitive benchmarking, and the need for scalable, future-proof customization. As various sectors push for lighter, stronger, and more sustainable materials, choosing the right supplier and solution is central to harnessing the full potential of prepreg technology. Close attention to evolving market data, application trends, and manufacturer advancements will empower stakeholders to drive operational efficiency and maintain a competitive edge in this rapidly changing arena.

(prepreg machine)

FAQS on prepreg machine

Q: What is a prepreg machine?

A: A prepreg machine is specialized equipment used to impregnate fibers or fabrics with resin to produce prepreg materials. These materials are commonly used in aerospace, automotive, and sports industries. Prepreg stands for "pre-impregnated" composite fibers.Q: Who are the leading prepreg machine manufacturers?

A: Some leading prepreg machine manufacturers include Mikrosam, Karl Mayer, and Shanghai LeadGo-Tech. These companies provide advanced and customized prepreg production solutions. They serve industries worldwide with innovative technologies.Q: What factors are driving the prepreg machine market growth?

A: The prepreg machine market is growing due to increasing demand for lightweight and high-strength materials in aerospace, automotive, and wind energy sectors. Advancements in composite technologies also contribute to market expansion. Sustainability and efficiency trends further boost market growth.Q: How do I choose the right prepreg machine for my application?

A: Consider your production volume, type of fibers and resins, and required automation level when choosing a prepreg machine. Consult with experienced manufacturers for tailored solutions. Factors such as maintenance support and energy efficiency are also important.Q: What are the main benefits of using prepreg machines?

A: Prepreg machines offer precise resin control, consistent quality, and faster production speeds. They improve the reliability of composite materials. This results in superior performance and cost efficiency for manufacturers.

Permeabil

Următorul