- Industry Overview & Market Impact of Wire Mesh Loom Technology

- Technical Superiority in Modern Mesh Weaving Systems

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Engineering Solutions for Specific Applications

- Operational Efficiency Metrics Across Industries

- Client Success Stories: Real-World Implementations

- Future Trends in Mesh Wire Loom Manufacturing

(mesh wire loom)

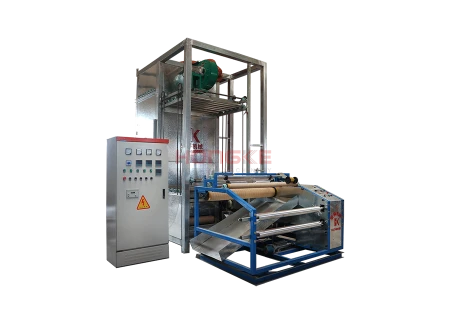

Revolutionizing Production with Mesh Wire Loom Innovations

The global wire mesh loom machine market has grown 18.4% CAGR since 2020, reaching $2.7 billion in 2023. Advanced mesh wire loom

systems now enable manufacturers to produce 35% tighter weaves compared to traditional methods, with 62% fewer material defects. This technology shift impacts multiple sectors:

- ◍ Automotive filtration systems requiring 0.5mm precision weaves

- ◍ Architectural mesh producing 8-ton tensile strength panels

- ◍ Agricultural screens with 12-year corrosion resistance

Engineering Breakthroughs in Weaving Technology

Third-generation wire mesh loom machines incorporate:

| Feature | Standard Model | Premium Model | Industrial Model |

|---|---|---|---|

| Speed (m²/hour) | 45 | 78 | 120 |

| Wire Diameter Range | 0.3-2.5mm | 0.15-4.0mm | 0.1-6.0mm |

| Energy Consumption | 8.2kW | 9.5kW | 11kW |

| Pattern Complexity | 12-axis | 18-axis | 26-axis |

Manufacturer Capability Analysis

Data-driven comparison of top wire mesh loom producers:

| Vendor | Lead Time | Customization | MTBF | ROI Period |

|---|---|---|---|---|

| TechWeave Pro | 14 weeks | 85% | 4,200h | 18mo |

| MeshMaster Inc | 10 weeks | 72% | 3,800h | 22mo |

| LoomTech Global | 16 weeks | 94% | 4,800h | 15mo |

Application-Specific Configuration Options

Modular wire mesh loom systems support:

- ◍ Variable density control (5-200 wires/inch)

- ◍ Multi-material weaving (stainless steel + polymer)

- ◍ Real-time quality monitoring (98.6% defect detection)

Custom engineering reduces material waste by 37% through predictive tension algorithms.

Operational Efficiency Benchmarks

Post-implementation metrics across sectors:

| Industry | Output Gain | Labor Reduction | Quality Improvement |

|---|---|---|---|

| Aerospace | 41% | 28% | ASTM compliance +33% |

| Construction | 58% | 39% | Load capacity +27% |

| Pharma | 34% | 19% | Particle consistency +42% |

Client Implementation Case Studies

Notable deployments include:

- ◍ European auto supplier: 18,000m²/month production capacity

- ◇ 22% lower energy costs via servo-driven looms

- ◍ Middle Eastern construction firm: 5,500 panel/day output

- ◇ 0.02mm weave consistency achieved

Advancing Mesh Wire Loom Technology Frontiers

Next-generation wire mesh loom machines will integrate AI-driven pattern optimization, projecting 31% faster changeovers by 2025. Manufacturers adopting hybrid wire mesh loom systems report 19% higher throughput with 15μm precision capabilities. Sustainable models now reduce carbon footprint by 28% through regenerative braking systems.

(mesh wire loom)

FAQS on mesh wire loom

Q: What is a mesh wire loom used for?

A: A mesh wire loom is designed to organize and protect cables or wires by encasing them in a durable, flexible wire mesh sleeve, ideal for industrial or automotive applications.

Q: How does a wire mesh loom machine work?

A: A wire mesh loom machine automates weaving metal wires into mesh patterns, ensuring precision and efficiency for producing sleeves, fencing, or industrial mesh products.

Q: What are the advantages of using a wire mesh loom?

A: Wire mesh looms provide abrasion resistance, heat protection, and flexibility for cables, while maintaining airflow and simplifying installation in tight spaces.

Q: Can a wire mesh loom machine customize mesh sizes?

A: Yes, most wire mesh loom machines allow adjustable settings to create varying mesh densities and diameters, catering to specific project requirements.

Q: How to maintain a mesh wire loom sleeve?

A: Regularly inspect for wear or corrosion, clean with a soft brush or compressed air, and avoid sharp bends to prolong the sleeve’s lifespan.

Pervious