As global demand increases for high-strength, corrosion-resistant mesh used in construction, fencing, mining, and filtration, investing in the right simli to'r to'qish mashinasi has become a strategic priority for manufacturers. Whether you are scaling up your operations or replacing outdated equipment, a modern simli to'r to'qish mashinasi brings unmatched precision, speed, and durability to your production line.

Eng yangi avlod mashinalari galvanizli po'lat sim, zanglamaydigan po'lat va guruch kabi turli xil materiallarga ishlov berish uchun mo'ljallangan. Ushbu mashinalar dasturlashtiriladigan boshqaruv tizimlari va yuqori kuchlanishli burilishlarni boshqarish tufayli kvadrat, to'rtburchaklar yoki moslashtirilgan to'r naqshlarini to'qishga qodir. Har bir chiqish rulosi bir xillik, minimal og'ish va tizimli yaxlitlikni aks ettiradi - xalqaro sifat standartlariga javob berishda hal qiluvchi ahamiyatga ega.

Choosing a reliable simli to'r to'qish mashinasi faqat chiqish haqida emas. Bu uzoq muddatli ishonchlilik haqida. Ishlab chiqaruvchilar endi zamonaviy avtomatlashtirish, real vaqtda monitoring va xavfsizlik tizimlarini taklif etadilar, bu esa mashinalarning doimiy, ko'pincha 24/7, minimal inson aralashuvi bilan ishlashiga imkon beradi. To'g'ri mashinaga jiddiy sarmoya kiritish ishlab chiqarishni yaxshilaydi, xatoliklarni kamaytiradi va vaqt o'tishi bilan ishlab chiqarish xarajatlarini optimallashtiradi.

How Mesh Weaving Machine Technology Powers Modern Industry

In sectors such as infrastructure development, energy, and industrial processing, the to'r to'quv mashinasi hal qiluvchi rol o‘ynaydi. Bu to‘r ishlab chiqarishning asosi bo‘lib, zavodlarga beton uchun armatura to‘rlari, filtrlash uchun ekranlar, qishloq xo‘jaligi va qurilish uchun to‘siq mahsulotlari ishlab chiqarish imkonini beradi. Qobiliyati a to'r to'quv mashinasi to create high-tensile and dimensionally stable mesh fabrics is essential for industries that demand both strength and precision.

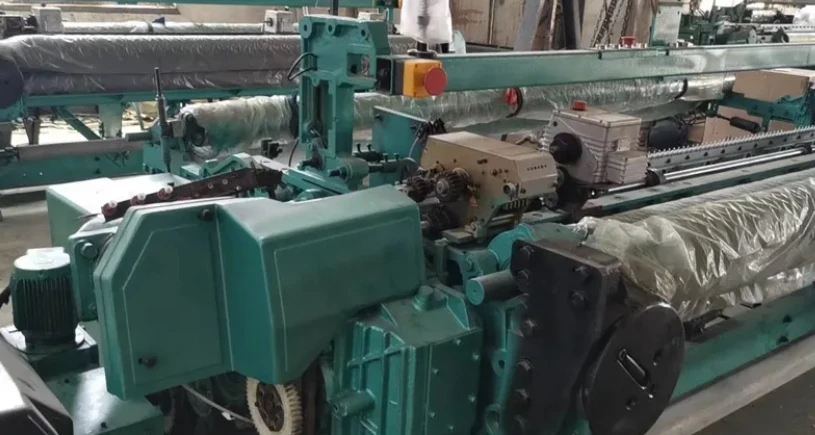

Zamonaviy mashinalar asosiy mexanik dastgohlardan tashqari rivojlandi. Bugungi to'r to'quv mashinasi includes servo motors, touch-screen PLC controls, and automated tension adjustment for seamless production across multiple mesh specifications. These systems allow fast switching between product types and greatly reduce setup times. Machines are often equipped with computerized diagnostics to monitor wear, tension irregularities, and yarn breaks, significantly reducing the chance of operational downtime.

The design of the to'r to'quv mashinasi itself has become more compact and energy-efficient. This allows businesses to fit multiple units within limited production space while still scaling output. Additionally, machines are now built with eco-friendly practices in mind, utilizing energy-efficient motors and minimizing wire waste through digital calibration. For any business focused on productivity and sustainability, a high-end to'r to'quv mashinasi becomes not just an asset but a competitive advantage.

What You Should Know About Industrial Weaving Machine Price and Value

Understanding the industrial weaving machine price Bu shunchaki tirnoqlarni solishtirishdan ko'proq narsadir. Xaridorlar har bir birlikning to'liq qiymatini - uning avtomatlashtirish darajasi, qurilish sifati, materialning moslashuvchanligi, foydalanish qulayligi va sotishdan keyingi yordamni baholashlari kerak. Kam xarajatli variant birinchi qarashda jozibador ko'rinishi mumkin, ammo uzoq muddatli ishlash, texnik xizmat ko'rsatish va energiyadan foydalanish uning umumiy egalik narxiga sezilarli ta'sir ko'rsatishi mumkin.

Entry-level sanoat to'quv mashinalari can start around $10,000 to $20,000 USD for semi-automatic models. These are typically suited to smaller workshops or niche production tasks. However, high-end fully automated systems designed for continuous production with minimal manual input can range from $30,000 to over $100,000 USD, depending on configuration. Prices often include essential features such as warp beam holders, weft feeders, mesh winding units, and tension controllers.

The industrial weaving machine price can also be affected by customization needs. Machines designed for fine-mesh output, heavy-gauge wire, or extra-wide weaving may require additional modules or reinforced components. Additionally, machines built with European or Japanese control systems may carry a higher price but offer better durability and interface reliability.

Beyond the base cost, it's essential to factor in services like training, installation support, remote diagnostics, spare part availability, and system upgrades. Leading manufacturers often bundle these into the machine price or offer long-term service packages, providing buyers peace of mind. Therefore, a higher upfront industrial weaving machine price may actually translate into better ROI over the machine's operational lifespan.

Why Leading Wire Mesh Weaving Machine Manufacturers Dominate the Global Market

Reputable wire mesh weaving machine manufacturers stolga mashinalardan ko'proq narsani keltiring - ular sanoat bilimlari, aniq muhandislik va uzoq muddatli hamkorlikni olib keladi. Bu kompaniyalar faqat uskunalar sotmaydi; ular sizni ishlab chiqarishni rejalashtirishdan tortib o'rnatish va texnik o'qitishgacha to'liq amalga oshirish jarayoni bo'ylab yo'naltiradi.

The most trusted wire mesh weaving machine manufacturers are often vertically integrated. This means they design and produce all major components in-house, including looms, feeders, and tension controllers. This level of control ensures greater consistency and reliability across every unit shipped. Manufacturers typically adhere to global standards such as CE and ISO certifications and offer performance warranties up to 5 years.

Bundan tashqari, ushbu ishlab chiqaruvchilar raqamli to'quv xaritalari, avtomatlashtirilgan xatolarni aniqlash va past shovqinli haydovchi tizimlari kabi rivojlanayotgan ishlab chiqarish tendentsiyalariga mos ravishda ilmiy-tadqiqot ishlariga faol sarmoya kiritadilar. Ularning mashinalari modulli bo'lib ishlab chiqilgan bo'lib, foydalanuvchilarga butun jihozni almashtirmasdan qismlar yoki dasturiy ta'minotni yangilash imkonini beradi. Global raqobat kuchaygani sari, eng yaxshi ishlab chiqaruvchilar aqlli integratsiyaga e'tibor berishadi - bu ularga imkon beradi wire mesh weaving machines to interface with factory ERP systems for real-time performance analysis.

Experienced manufacturers also provide operational demo videos, virtual factory tours, and client references to showcase machine performance. Many offer tailored service contracts that include technician visits, spare part kits, and 24/7 technical support in multiple languages. Working with elite wire mesh weaving machine manufacturers ensures not just a quality machine but a long-term competitive edge.

How to Choose the Right Mesh Weaving Machine for Your Production Goals

Choosing the best to'r to'quv mashinasi requires a clear understanding of your product specifications, production targets, and budget. A fencing company may need a heavy-duty loom capable of weaving thick-gauge wire for high-security mesh, while a filtration equipment supplier may prioritize ultra-fine mesh accuracy. The right machine will meet these demands while offering adaptability for future product variations.

Start by identifying the wire diameters and mesh openings required for your typical products. Ensure the to'r to'quv mashinasi siz foydalanmoqchi bo'lgan materiallarni - galvanizli po'latdan, zanglamaydigan po'latdan, guruchdan yoki PVX bilan qoplangan simdan foydalana oladi. Bir smenada maqsadli ishlab chiqarishingizni va avtomatlashtirish xususiyatlari mehnatga bog'liqlik va xatolik darajasini kamaytirishga yordam beradimi yoki yo'qligini ko'rib chiqing.

Also, think about integration. Does the machine align with your existing production layout? Can it be upgraded later as your factory expands? Machines that allow interchangeable mesh rollers, quick-setting adjustments, and digital mesh pattern input offer greater long-term flexibility.

Finally, consult with a qualified manufacturer or supplier who can evaluate your specific production environment. They may recommend modifications to standard machines or suggest auxiliary equipment such as automatic spooling systems, wire straighteners, or cooling stations. The right to'r to'quv mashinasi will enhance your workflow, deliver consistent quality, and support your business goals as market demands evolve.

simli to'r to'qish mashinasi Tez-tez so'raladigan savollar

What types of wire can a wire mesh weaving machine process?

A simli to'r to'qish mashinasi can handle a variety of materials, including stainless steel, galvanized wire, brass wire, and PVC-coated wire. The machine's configuration can be adjusted for different wire diameters and tensile strengths, making it suitable for both light-duty mesh and heavy industrial applications.

Sanoat to'quv mashinasi narxiga nima kiradi?

The industrial weaving machine price often includes the core machine, control systems, warp and weft feeders, basic tooling, and a warranty. Some suppliers also offer operator training, spare parts, installation assistance, and digital control upgrades. Always request a detailed quotation that breaks down what's included.

Can mesh size and width be adjusted on the same machine?

Ha, eng zamonaviy mesh weaving machines are built with adjustable parameters. Operators can change the mesh opening size, fabric width, and wire spacing using digital inputs or mechanical dials. Some advanced models offer touchscreen PLC control for faster switching between product specifications.

How do I choose between manual, semi-automatic, and fully automatic machines?

Your choice depends on your production volume, labor costs, and product precision requirements. Manual machines are cheaper but labor-intensive. Semi-automatic wire mesh weaving machines strike a balance and are suitable for medium-scale operations. Fully automatic machines offer the highest efficiency and are ideal for continuous, large-scale production.

What kind of support do wire mesh weaving machine manufacturers provide after purchase?

Top-tier wire mesh weaving machine manufacturers provide extensive after-sales support, including remote diagnostics, video tutorials, spare parts kits, and even on-site technician services. They may also offer software updates, technical consultation, and performance audits to ensure your machine continues operating at peak capacity.

O'tkazuvchan