In the world of metal processing and manufacturing, selecting a high-quality wire drawing machine for sale is crucial to meeting demand and ensuring efficiency. These machines are the foundation for producing the raw materials used in numerous industries—from construction and electrical cable production to fence mesh and fastener manufacturing. Investing in a modern, high-performance wire drawing machine for sale can dramatically increase your productivity, minimize material waste, and improve overall product quality.

A wire drawing machine works by pulling metal wire through a series of dies to reduce its diameter and improve its surface finish. The resulting wire is stronger, smoother, and better suited for further manufacturing processes. Whether you are drawing steel, copper, aluminum, or other alloys, today’s advanced wire drawing machines offer the ability to run at high speeds with precise control over wire thickness, tension, and coiling.

When browsing a wire drawing machine for sale, it’s important to consider key features such as motor power, number of dies, cooling systems, automation level, and safety enhancements. The most efficient machines on the market today include fully enclosed structures, digital interface panels, and real-time speed regulation to ensure consistency. For any manufacturing company looking to streamline wire production and meet growing market needs, purchasing a reliable wire drawing machine for sale is not just an upgrade—it’s a strategic decision.

Window Screen Machine Technology and Its Role in Everyday Manufacturing

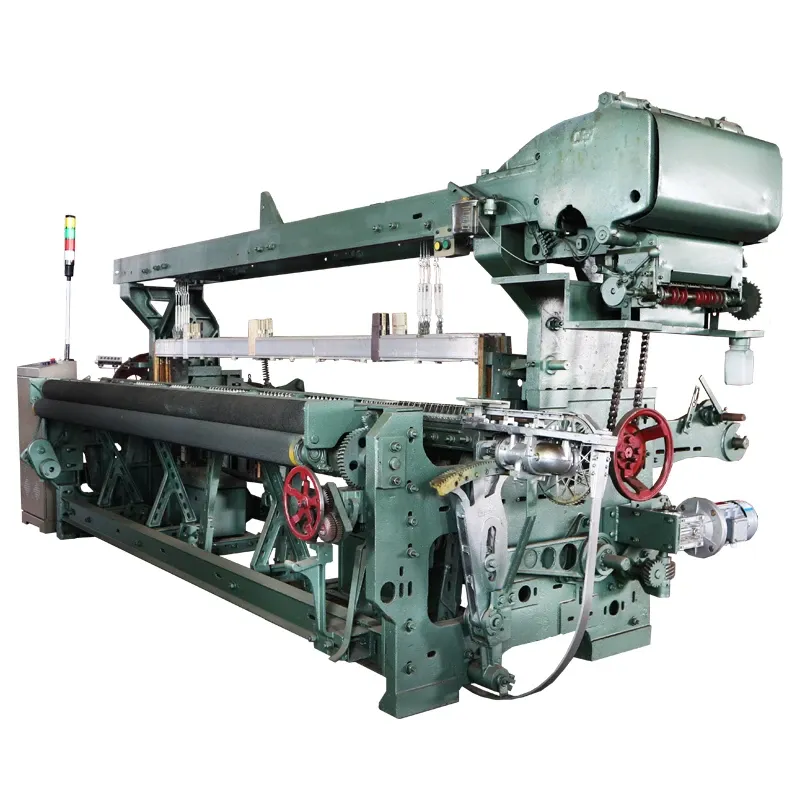

For industries involved in the production of insect protection systems, household goods, or building hardware, the window screen machine is a vital part of the production line. It is specifically designed to weave or assemble mesh screens that are used in homes, commercial buildings, and industrial facilities around the world. The window screen machine can manufacture a variety of mesh sizes and materials, including fiberglass, aluminum, and stainless steel.

Modern machines feature automatic yarn feeding, tension control, edge trimming, and high-speed weft insertion systems. This allows them to deliver uniform window screens that meet exacting quality standards. Additionally, intelligent patterning systems let manufacturers adjust screen texture and density with a few simple commands. These features are indispensable for producers who want to offer screen mesh products for various climates, architectural styles, and customer preferences.

With the growing demand for ventilation and protection from insects without compromising visibility or airflow, more manufacturers are adopting the latest window screen machine technology to increase production efficiency and product appeal. Machines can be tailored for roll-form production, pre-cut panels, or reinforced mesh screens used in security windows and storm-proof designs.

The market for window screens continues to expand, especially with increased construction activities across developing and developed nations. As this sector grows, investing in an efficient and high-speed window screen machine ensures manufacturers remain competitive, deliver higher volumes, and provide consistent quality at scale.

Boost Productivity with Modern Window Screen Making Equipment

In today’s competitive industrial landscape, using the right window screen making equipment can make the difference between a stagnant operation and a flourishing business. This category includes a full set of machinery used for producing, cutting, edging, and rolling window screens, whether made from wire, fiberglass, or synthetic materials. The best window screen making equipment offers modular designs, meaning it can be customized and scaled as your production grows.

State-of-the-art equipment includes warping machines, coating systems, weaving machines, inspection tables, and rolling units—all designed to work seamlessly for maximum efficiency. These machines help ensure that every meter of window screen material meets the exact required standards. Edge binding, trimming, and gluing systems make the screens ready for use immediately, reducing the need for manual post-processing.

The ideal window screen making equipment offers touchscreen controls, automated size conversion, and programmable memory for custom batches. This helps businesses reduce labor costs, minimize waste, and improve throughput. In addition, new smart machines come equipped with sensors and diagnostic alerts, so maintenance teams can detect and resolve faults quickly without stopping production lines.

From large-scale factories producing thousands of rolls per day to niche producers making designer screens, the scalability and flexibility of window screen making equipment is a game-changer. With the right equipment, companies can adapt to changing market trends, meet urgent customer needs, and maintain a reputation for excellence.

Why More Global Buyers Choose Wire Drawing Machine China Manufacturers

As international demand for precision wire products increases, manufacturers are looking for reliable sources of equipment that combine affordability, performance, and long-term support. That’s why more and more buyers are turning to wire drawing machine China suppliers. These manufacturers have gained global recognition for their engineering capabilities, production capacity, and commitment to quality.

Chinese wire machinery manufacturers offer a wide variety of configurations—from dry drawing to wet drawing systems—capable of processing various metals and wire diameters. Machines built in China are now known for their robust design, user-friendly interfaces, and energy efficiency. Many include high-grade carbide dies, inverter-controlled speed systems, and efficient water-cooling technologies that extend machine lifespan and reduce running costs.

One key reason for the popularity of wire drawing machine China suppliers is the ability to offer customized machinery at competitive prices. Whether clients require compact units for smaller spaces or high-speed multi-line machines for industrial-scale output, Chinese manufacturers can deliver tailored solutions without excessive delays or overhead costs. In addition, many suppliers offer technical support in multiple languages, ensuring seamless setup, maintenance, and training.

Another strong advantage is supply chain accessibility. Most components used in the machines—from motors to steel frames—are locally sourced in China’s advanced industrial zones. This allows for quicker production cycles, easy parts replacement, and streamlined upgrades. As Chinese manufacturers continue to enhance their R&D capabilities and global service networks, wire drawing machine China is becoming the preferred choice for both emerging and established markets alike.

Integrating Wire Drawing and Window Screen Machines for Seamless Mesh Production

For manufacturers involved in both wire processing and mesh production, combining a wire drawing machine for sale with advanced window screen making equipment can result in a seamless, end-to-end production ecosystem. This integration allows companies to draw their own wire to precise specifications and feed it directly into mesh production lines, ensuring better quality control and reducing reliance on external suppliers.

By controlling the entire process—from raw material to finished product—factories gain full oversight of material properties, wire diameters, and mesh consistency. This closed-loop production strategy improves efficiency, reduces costs, and enhances responsiveness to customer orders. It also ensures that the characteristics of the drawn wire—tensile strength, flexibility, coating adherence—are ideal for use in screen manufacturing.

Integration also enables smart factory planning. Machines can be synced through centralized PLC systems, allowing for real-time performance tracking, batch scheduling, and predictive maintenance alerts. This level of digital coordination supports Industry 4.0 practices and prepares factories for future expansions.

Whether you’re producing insect screens, architectural mesh, or industrial-grade netting, the combination of a wire drawing machine China system and a reliable window screen machine is a strategic investment. It aligns raw material preparation with finished product manufacturing, creating a powerful competitive advantage in a rapidly evolving market.

window screen machine Preguntas frecuentes

What types of metal can a wire drawing machine for sale process?

A wire drawing machine for sale can handle various types of metal, including low-carbon steel, high-carbon steel, stainless steel, copper, aluminum, and brass. The machine reduces wire diameter by drawing it through dies, improving tensile strength and surface smoothness. Specific configurations may be optimized for certain materials based on the drawing method (wet or dry) and die material.

How does a window screen machine differ from regular mesh machines?

A window screen machine is specially designed to produce mesh with finer wire diameters and tighter tolerances suitable for household and commercial window applications. These machines often include advanced tension control, automatic cutting, and rolling features to ensure smooth edges and precise sizing. They may also accommodate fiberglass or plastic yarns, which are not typical in industrial mesh production.

What are the key features to look for in window screen making equipment?

The best window screen making equipment should include high-speed weaving capabilities, automated tension and width adjustment, programmable batch control, and quality inspection stations. Features like automatic trimming, edge sealing, and digital interface panels can significantly enhance productivity and reduce manual labor requirements.

Why are wire drawing machine China models often more affordable?

Wire drawing machine China models are more affordable due to cost-effective manufacturing practices, locally sourced components, and large-scale production capacity. Despite lower prices, many of these machines meet or exceed international quality standards. Additionally, Chinese suppliers often offer customization, fast lead times, and comprehensive after-sales support, adding excellent value for global buyers.

Can a single production line include both wire drawing and window screen production?

Yes, integrating a wire drawing machine for sale with window screen making equipment is not only possible but highly efficient. This setup allows manufacturers to control wire properties and directly feed the drawn wire into screen production machines. It reduces logistics, enhances quality assurance, and enables full-cycle production from raw material to finished product.