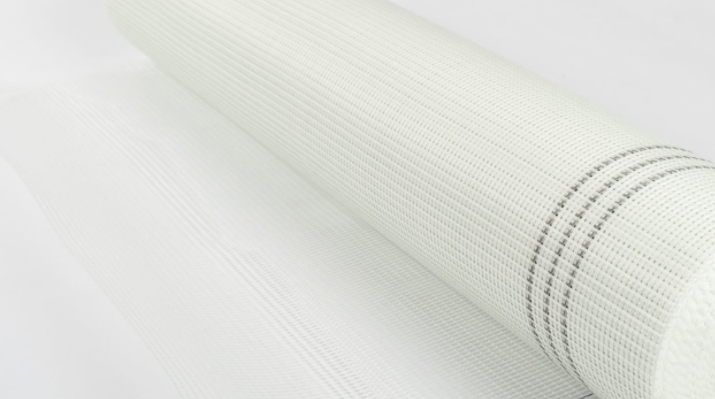

Fiberglass Mesh Machine

To make fiberglass mesh,you need three kinds machines:warping machine,weaving machine and gule coating machine.it has 1m,15m,2m width and other size.

Fiberglass mesh is often applied in construction for wall reinforcement, especially in external wall insulation systems. It enhances the stability and strength of the wall surface.

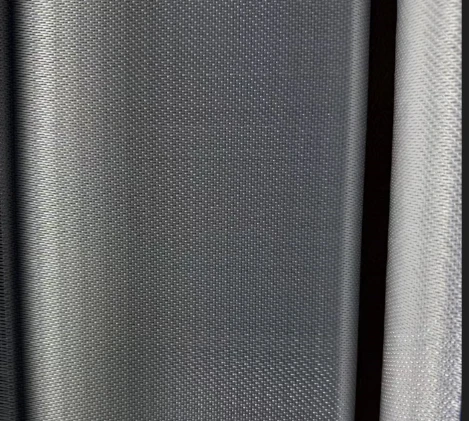

Fiberglass Mosquito Net Machine

Fiberglass Window Screen,Fiberglass Folding Window Screen,fiberglass mosquito net Production Line, Finished Product Specification 14 * 17 16 * 18 20 * 20, Fiberglass Window Screen Production Line Main Equipment:PVC Coating machine, warping machine, weaving machine, shaping machine,quality inspection machine

Fiberglass Fireproof Cloth Production Line

Product model 200g-600g, for making fiberglass fireproof cloth, fiberglass cloth

Three proof cloth,3732 fireproof cloth,3784 fireproof cloth

Main equipment of production line: warping machine, weaving machine, glue coating machine

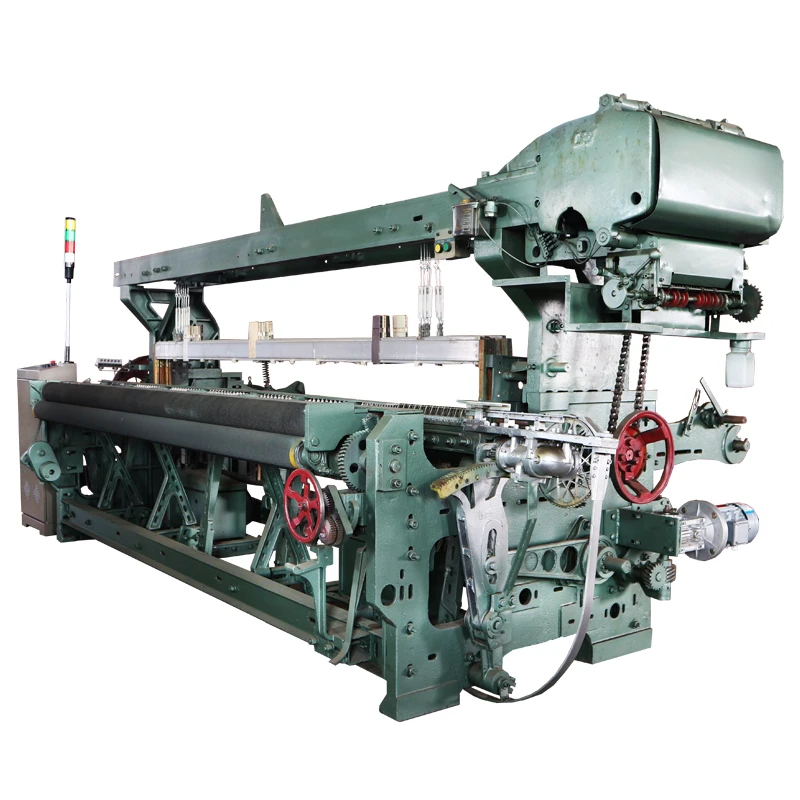

Fiberglass Woven Roving Machine

This production line is mainly composed of weaving machines and yarn racks. Hongke's main models include 788 weaving machines and high-speed weaving machines,yarn rack is composed of the same parts. The production process is that the yarn passes through the porcelain eye steel buckle from the spinning frame, wraps half a circle around the tension shaft, wraps half a circle around the false warp axis, and enters the weaving machine at the rear beam shaft.

Fiberglass Mesh Tape Machines

Fiberglass mesh tape machine is a kind of equipment used for manufacturing fiberglass mesh tape. It plays a crucial role in the production process of fiberglass products.