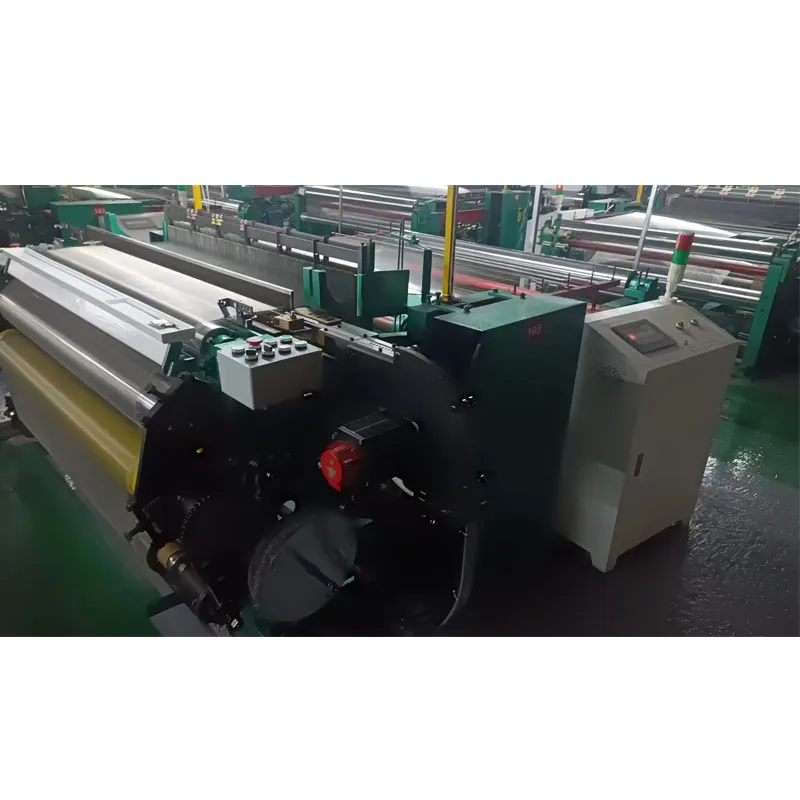

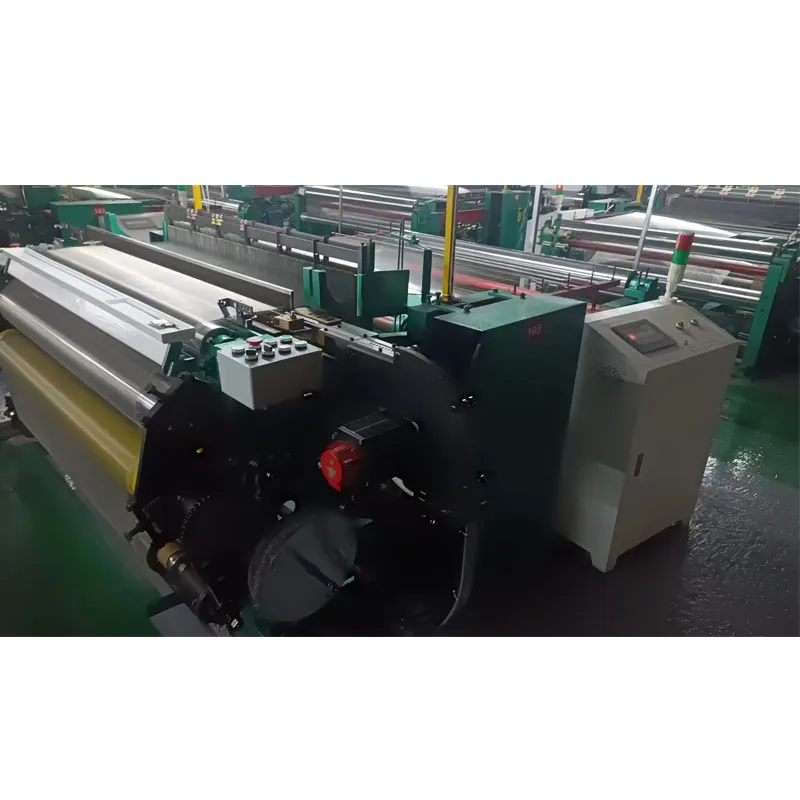

In the ever-evolving world of industrial manufacturing, a machine for weaving forms the backbone of critical sectors, ensuring the efficient creation of high-quality wire mesh products. Modern weaving systems—featuring advancements like power loom warping machine integration—have set new benchmarks in precision, durability, and versatility. Among these, the Stainless Steel Wire Mesh Weaving Machine stands at the forefront, marrying advanced engineering with practical application across oil & petrochemical, metallurgy, water treatment, and more.

- According to Grand View Research (2023), the global market value for wire mesh weaving machinery is projected to reach USD 6.4 billion in 2027, reflecting a 5.8% CAGR from 2021-2027.

- Demand is driven by increasing requirements for corrosion-resistant and high-precision wire mesh in filtration, mining, and petrochemical industries.

- Integration of CNC controls and ISO-standardized testing is standard for next-generation machine for weaving solutions.

- Emphasis on automation, energy efficiency, and digital fault diagnostics in power loom warping machine upgrades.

- Material Selection: Uses premium 304/316L stainless steel wire conforming to ISO/TS 15510, ensuring excellent corrosion and chemical resistance.

- Manufacturing Technologies: Sophisticated forging, CNC machining, and precision assembly processes guarantee ±0.03mm tolerance and high repeatability.

- Certification: Designed and tested per ISO 9001:2015 quality systems, with critical parts passing ANSI/AISI/SUS mechanical endurance standards.

- Wire feeding, heddle shedding, beat-up, and take-up are fully servo-motorized for smoother warping, stable mesh aperture, and adjustable density.

- Automated tension control and PLC-based diagnostics maximize uptime and output consistency.

- Life Span: Designed for continuous operation exceeding 80,000 production hours with minimal downtime.

Spools loaded

ISO grade wire

Arranging warps

by power loom warping machine

Forming mesh

openings

Compact mesh

for desired density

Automatic coiling

of finished mesh

| Model | Wire Diameter (mm) | Mesh Width (mm) | Mesh Count (mesh/inch) | Speed (RPM) | Power (kW) | Material | Control System |

|---|---|---|---|---|---|---|---|

| HK-1000 | 0.025–0.35 | 200–1000 | 8–400 | 85–120 | 3.7 | 304/316L SS wire | PLC (Siemens) |

| HK-1300 | 0.03–0.40 | 300–1300 | 10–350 | 80–110 | 4.0 | 304/316L SS wire | PLC (Mitsubishi) |

| HK-1600 | 0.035–0.50 | 500–1600 | 6–250 | 60–100 | 5.5 | Carbon steel/SS wire | PLC (Omron) |

| Parameter | a weaving machine (Traditional) |

Power Loom Warping Machine | Stainless Steel Wire Mesh Weaving Machine |

|---|---|---|---|

| Operation Mode | Manual/Semi-auto | Semi/Auto | Full Automation |

| Material Compatibility | Carbon steel, brass | SS, Carbon steel | 304/316L Stainless Steel, Carbon, Alloy |

| Precision (Aperture mm) | ±0.08 | ±0.06 | ±0.03 |

| ISO/ANSI Certification | No | ISO 9001 | ISO 9001, ANSI/AISI |

| Output (per day) | ~380 m2 | ~510 m2 | ~740 m2 |

| Energy Efficiency | Low | Medium | High (≤3.7kWh/100m2) |

| Warranty | 1 Year | 2 Years | 3 Years |

- Petrochemical: Fine mesh filtration for catalyst protection; resistant to H2SO4, NaOH, and hydrocarbons.

- Metallurgy: Robust mesh for high-temperature sieving; longevity in acidic, oxidizing, or salt-rich atmospheres.

- Water Treatment: Non-reactive wire mesh screening; prevents biofouling and corrosion, certified for potable water under FDA 21 CFR 175.300.

- Food Processing: Hygienic, easy-to-clean, non-toxic mesh solutions; supports HACCP requirements.

- Automotive: Precision filters in fuel injection and emission control systems.

Corrosion Resistance: 316L stainless steel construction ensures mesh lifespan up to 3.5× longer than carbon steel alternatives.

Service uptime: Modular design allows field repairs in <2 hours per average breakdown, minimizing process interruptions.

| Company | Core Product | R&D Years | Certification | Global Installations | Guarantee |

|---|---|---|---|---|---|

| APH Machinery | Stainless Steel Wire Mesh Weaving Machine | 23 | ISO 9001, ANSI | 2300+ | 3 Years |

| Atlas Looms | Power Loom Warping Machine | 17 | ISO 9001 | 1200+ | 2 Years |

| Jiangsu Weave | a weaving machine | 12 | ISO 14001 | 700+ | 1.5 Years |

- Material Customization: Mesh weaving with alloys (SS304, 316L, monel, phosphor-bronze, etc.) for extreme environments.

- Dimension Matching: Custom mesh width from 80–2000mm to suit project requirements (filtration, separation, screening).

- Pattern Options: Plain weave, twill weave, Dutch weave as per ASTM E2016.

- Control Integration: Bespoke PLC upgrades (Siemens, Schneider), IoT-enabled diagnostics, and data export features.

- Service: 3-year guarantee, 24/7 engineer hotline, on-site installation & start-up training, 36-hour remote diagnostics.

- Delivery Cycle: 20–28 working days (typical); expedited solution on request.

- Compliance: CE/ISO/FDA certificates for international buyers.

Project: Replacement of acid-resistant filter mesh in catalytic cracking line, 2023/Q2.

Push Points:

- Weaving machines delivered: 4 x HK-1300

- Upgraded to 316L fine wire, 160 mesh/inch, ±0.02mm aperture tolerance

- Downtime reduced by 72% (from 10.5h/month to 3.0h/month)

- Annual mesh replacement cost savings: 48.9%

- On-site installation by APH, safety/quality verified per ISO 9001 and SGS audit

- End-user review: "Seamless integration, high reliability, and outstanding corrosion resistance."

- As a machine for weaving technology continues to evolve, the Stainless Steel Wire Mesh Weaving Machine leads the industry in precision, durability, and adaptability. Backed by global standards (ISO, ANSI), documented service experience, and comprehensive after-sales support, it delivers lasting value to petrochemical, metallurgy, water treatment, and other sectors.

- For detailed technical discussions, industry updates, and peer experiences, refer to:

- Manufacture with confidence: leverage the best-in-class a machine for weaving technology for reliability, precision, and return on investment.

Pervious