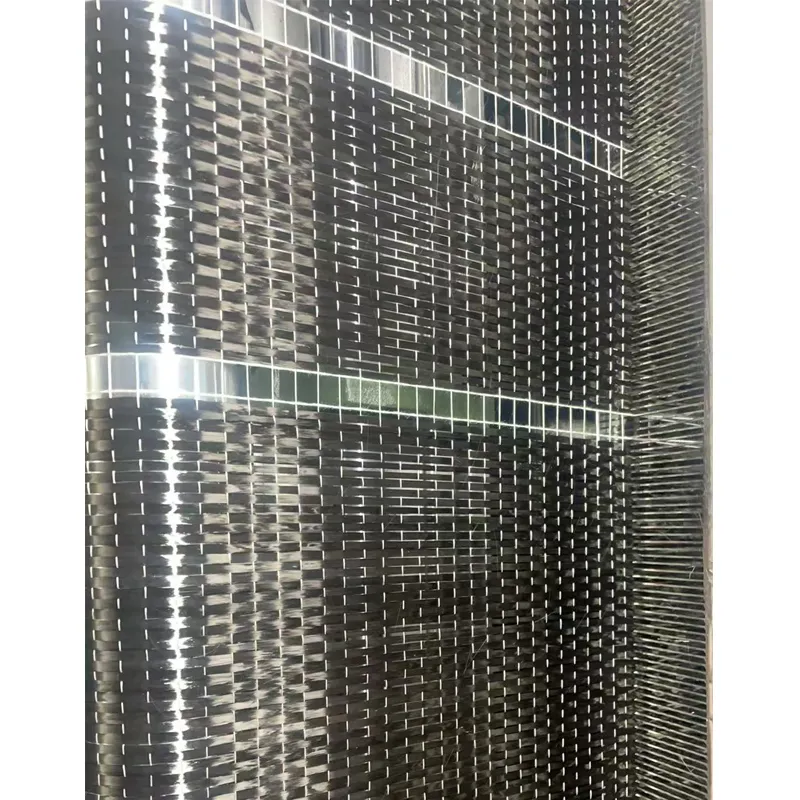

Carbon Fiber Mesh Rapier Loom

The Carbon Fiber Mesh Rapier Loom is specialized equipment designed for manufacturing carbon fiber mesh. It integrates advanced technologies and precise mechanical structures to ensure the high-quality production of carbon fiber mesh. This versatile machine can be adjusted to produce different types of carbon fiber mesh with various specifications, such as different mesh densities, fiber orientations, and widths, to meet the diverse needs of aerospace, automotive, and sporting goods applications.

Key Advantages: High-tension weaving capability, precision alignment systems, multi-axis carbon fiber handling, and energy-efficient operation.

Industry Development and Technical Innovations

The global market for carbon fiber machine technology has grown at 12.4% CAGR since 2020 (Composites World, 2023). Modern carbon weaving machine systems incorporate automated tension control and AI-powered defect detection to ensure consistent fabric quality. Carbon fiber weaving looms from leading manufacturers like Anping Hongke now feature servo-motor drives and HMI interfaces that reduce setup time by 40% compared to conventional models.

Recent innovations in carbon fibre weaving machine technology focus on handling ultra-high modulus fibers (over 600 GPa) while minimizing filament damage. According to the Journal of Composite Materials, next-generation machines incorporate laser positioning systems that achieve warp alignment accuracy within ±0.05mm, significantly improving the mechanical properties of the final composite products.

Technical Specifications and Performance Data

| Parameter | Standard Model | Advanced Model | Industrial Model |

|---|---|---|---|

| Weaving Speed | 120 picks/min | 220 picks/min | 350 picks/min |

| Max. Fabric Width | 1.8 meters | 3.2 meters | 5.4 meters |

| Tension Control | ±5% | ±2.5% | ±0.8% |

| Fiber Compatibility | 3K-12K | 1K-24K | 0.5K-50K |

| Power Consumption | 8 kW | 12 kW | 22 kW |

Industrial Applications

Modern carbon fiber weaving machines enable production of specialized fabrics for demanding applications:

Aerospace: Production of lightweight structural components with complex weaves (angle interlock, 3D orthogonal) meeting AS9100 standards.

Automotive: High-volume manufacturing of carbon fiber parts for electric vehicles, reducing weight while maintaining crash safety requirements.

Renewable Energy: Creation of durable wind turbine blades with optimized fiber orientation for maximum strength-to-weight ratio.

Technical FAQ: Carbon Fiber Machinery

What tension control systems are used in modern carbon fiber looms?

Modern carbon fiber weaving looms utilize closed-loop servo systems with load-cell feedback that maintain tension within ±1% variance. Anping Hongke machines feature adaptive algorithms that automatically compensate for spool diameter changes during unwinding.

What are the standard widths for industrial carbon weaving machines?

Industrial carbon weaving machines offer widths from 1m (prototyping) to 5m+ (aerospace production). The HK-CF5200 model from Anping Hongke supports 3.2m standard width with extension capability up to 5.4m.

How does fiber spread technology affect fabric quality?

Precise fiber spreading is critical for eliminating gaps in carbon fiber fabrics. Our carbon fibre weaving machines employ precision rollers with adjustable surface texture and spacing that optimize spread uniformity.

What safety certifications apply to carbon fiber machinery?

Industrial carbon fiber machines must comply with CE Machinery Directive (2006/42/EC), ISO 12100 safety standards, and NFPA 86 electrical requirements for high-temperature industrial equipment.

What maintenance is required for carbon weaving equipment?

Daily lubrication of reed components, monthly tension sensor calibration, and biannual servo motor alignment checks ensure optimal performance in carbon weaving machines.

How does rapier technology improve carbon fiber weaving?

Rapier systems in carbon fiber looms precisely control yarn transfer without abrasive contact. Flexible rapier heads reduce filament breakage below 0.3%, significantly lower than projectile shuttle systems.

What automation interfaces do modern machines support?

Anping Hongke carbon fiber machines feature OPC UA-compatible controls that integrate with MES systems, supporting TCP/IP, Profinet, and EtherCAT communication protocols.

Expert Perspectives

"The precision of modern carbon fiber weaving machines allows fabric designers to create architecturally complex preforms with virtually no distortion. This advancement is revolutionizing structural composite applications where fiber orientation precision translates directly to performance improvements."

"Manufacturers like Anping Hongke have significantly improved loom efficiency with tension control systems that reduce material waste by 15-22%, making carbon fiber composites more viable for high-volume automotive applications."

Future Outlook

The carbon fiber machine market is projected to reach $2.8B by 2028 according to CompositesWorld Market Report. Key developments include integration of IoT predictive maintenance, machine learning-based quality control that reduces defects by up to 40%, and multi-axis robotic systems capable of creating complex 3D woven structures. Anping Hongke continues to innovate with next-generation machines capable of processing hybrid carbon-aramid yarns with individual strand tension control.

Industry Resources:

CompositesWorld Market Analysis | SAMPE Technical Papers | Composites Part A: Applied Science

Pervious