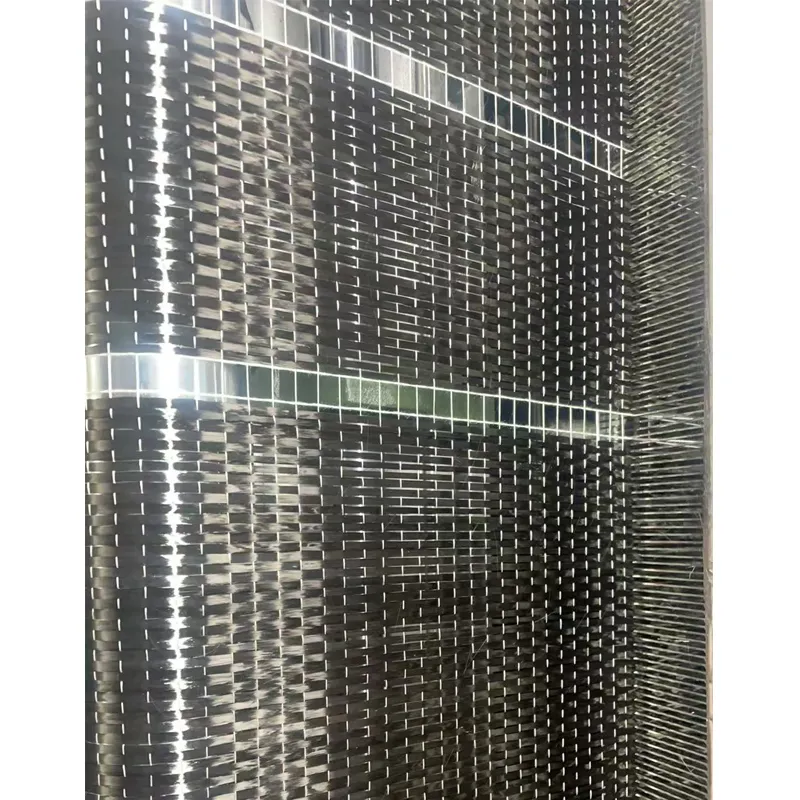

Carbon Fiber Mesh Rapier Loom: Precision Engineering for High-Performance Textile Production

Discover the cutting-edge technology behind the Carbon Fiber Mesh Rapier Loom, designed to revolutionize carbon fiber mesh manufacturing with unparalleled accuracy and efficiency.

Introduction to the Carbon Fiber Mesh Rapier Loom

The Carbon Fiber Mesh Rapier Loom represents a significant advancement in textile manufacturing technology, specifically tailored for producing high-quality carbon fiber mesh. Developed by Anping Hongke Wire Mesh Machinery Factory, this machine integrates advanced mechanical systems and precision engineering to meet the demands of modern industrial applications. With its innovative design, the loom ensures consistent product quality, enhanced durability, and adaptability to various production requirements.

Key Features and Technological Innovations

The Carbon Fiber Mesh Rapier Loom incorporates several groundbreaking features that set it apart from traditional weaving machines. Below are the core technologies that define its performance:

1. Servo-Controlled Reducer for Coiling and Feeding

The loom utilizes a servo-controlled reducer to manage the coiling and feeding processes. This system enhances the accuracy of product latitude and longitude density, ensuring uniformity in the final mesh. The servo control mechanism allows for precise adjustments, making the operation more coordinated and reducing the risk of material wastage. Additionally, the improved density control extends the service life of the machine, offering long-term cost savings for manufacturers.

2. Simplified Cam Openings

The cam opening system is designed for simplicity and reliability. By employing a low-failure-rate mechanism, the loom minimizes downtime and maintenance requirements. The rigid connecting rod lifting mechanism enables precise adjustment of the lifting frame, ensuring smooth operation and a prolonged service life. This feature is particularly beneficial for high-volume production environments where consistent performance is critical.

3. Rigid Sword Bars with Carbon Fiber Construction

The rigid sword bars are crafted from carbon fiber and equipped with a small sword strap. This combination offers a cost-effective, durable solution for weaving applications. The carbon fiber material ensures that the sword handle remains undamaged during operation, preserving the integrity of the carbon fiber yarn. This design makes the loom ideal for producing high-strength, lightweight mesh structures.

4. Acrylic Fake Warp Shafts for Uniform Tension

The loom employs acrylic rollers to create fake warp shafts, which are specifically optimized for carbon fiber yarn. The soft rubber material resists the effects of temperature fluctuations, ensuring consistent warp tension. This results in products with excellent flatness and uniformity, meeting the stringent requirements of industries such as aerospace and automotive manufacturing.

5. Tension Yarn Frame with Twisted Rod Design

The tension yarn frame utilizes a twisted rod type tension holder combined with a high-end stainless steel tube for adhesive separation. This design effectively protects the flatness of the yarn, preventing defects that could compromise the quality of the final mesh. The robust construction ensures reliable performance even under demanding conditions.

Technical Specifications Table

| Parameter | Details |

|---|---|

| Model | Carbon Fiber Mesh Rapier Loom |

| Control System | Servo-controlled reducer |

| Cam Mechanism | Rigid connecting rod for precise adjustment |

| Sword Bars Material | Carbon fiber with small sword strap |

| Fake Warp Shafts | Acrylic rollers for uniform tension |

| Tension Yarn Frame | Twisted rod type with stainless steel tube |

| Service Life | Extended through precision engineering |

Applications and Industry Use Cases

The Carbon Fiber Mesh Rapier Loom is designed to cater to a wide range of industrial applications, including:

- Aerospace: Production of lightweight, high-strength mesh for aircraft components.

- Automotive: Manufacturing of carbon fiber reinforcements for vehicle bodies and interiors.

- Construction: Creation of durable mesh for structural support and insulation materials.

- Medical: Fabrication of specialized mesh for prosthetics and orthopedic devices.

Its versatility and precision make it an ideal solution for industries requiring high-quality, custom-made carbon fiber products.

Company Background: Anping Hongke Wire Mesh Machinery Factory

Anping Hongke Wire Mesh Machinery Factory is a leading manufacturer of advanced textile machinery, specializing in carbon fiber and wire mesh production equipment. With years of experience in the industry, the company has established a reputation for delivering reliable, high-performance solutions to clients worldwide. Their commitment to innovation and quality ensures that their products meet the evolving needs of modern manufacturing.

As a trusted name in the field, Anping Hongke continues to invest in research and development to enhance the efficiency and capabilities of their machinery. Their products are designed to comply with international standards, ensuring safety, durability, and optimal performance in diverse industrial environments.

Why Choose the Carbon Fiber Mesh Rapier Loom?

The Carbon Fiber Mesh Rapier Loom offers several advantages that make it a preferred choice for manufacturers:

- Enhanced Accuracy: The servo-controlled system ensures precise density and tension control, minimizing defects.

- Increased Efficiency: The simplified cam mechanism and durable components reduce maintenance and downtime.

- Cost-Effectiveness: The use of carbon fiber and acrylic materials lowers long-term operational costs.

- Adaptability: The loom can be adjusted to produce mesh with varying specifications to suit different applications.

These benefits make the loom a valuable asset for businesses seeking to improve productivity and product quality.

Industry Standards and Compliance

The development of the Carbon Fiber Mesh Rapier Loom aligns with the standards set by the National Institute of Standards and Technology (NIST), which plays a critical role in advancing manufacturing technologies. According to NIST guidelines, precision engineering and material science innovations are essential for ensuring the reliability and performance of industrial equipment (NIST, 2023). By adhering to these standards, Anping Hongke Wire Mesh Machinery Factory ensures that their products meet the highest levels of quality and safety.

For further information on NIST's role in manufacturing standards, visit NIST's official website.

Conclusion

The Carbon Fiber Mesh Rapier Loom is a testament to the power of innovation in textile manufacturing. With its advanced features, precise engineering, and adaptability, this machine is poised to transform the production of carbon fiber mesh across multiple industries. Whether you are in aerospace, automotive, or construction, the loom provides a reliable solution to meet your specific requirements.

For more details about the product and its specifications, visit the Carbon Fiber Mesh Rapier Loom page on Anping Hongke Wire Mesh Machinery Factory's official website.

Pervious