Carbon Fiber Mesh Rapier Loom: Advanced Weaving Solutions for High-Performance Textiles

As a leading manufacturer in the textile machinery industry, Anping Hongke Wire Mesh Machinery Factory specializes in delivering cutting-edge solutions for high-performance textile production. Our Carbon Fiber Mesh Rapier Loom combines precision engineering with advanced technology to meet the demanding requirements of modern industrial applications. This article explores the features, benefits, and applications of our innovative weaving machine, designed to revolutionize your textile manufacturing processes.

What is a Carbon Fiber Mesh Rapier Loom?

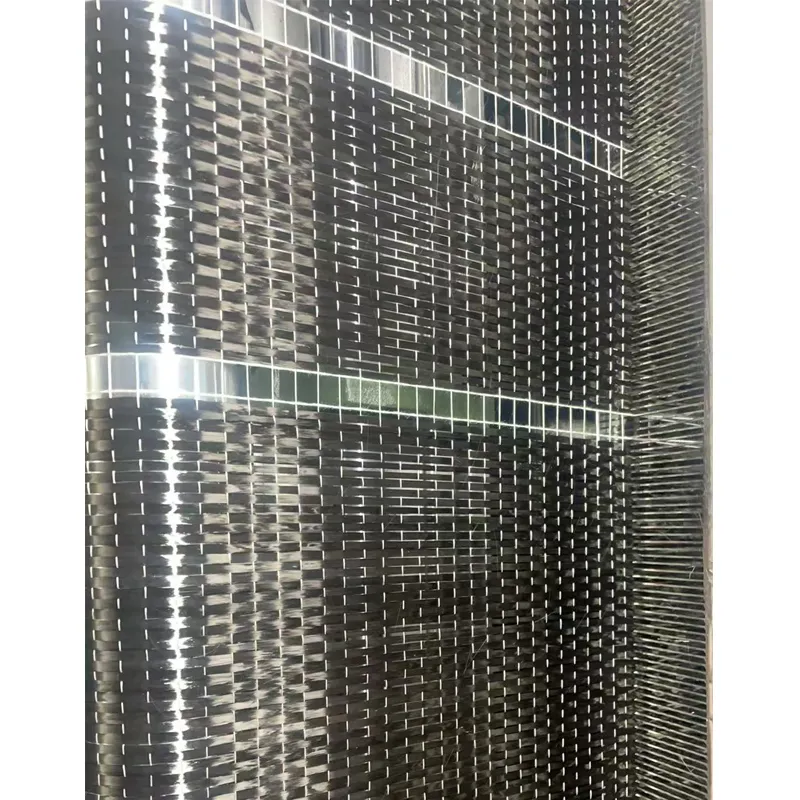

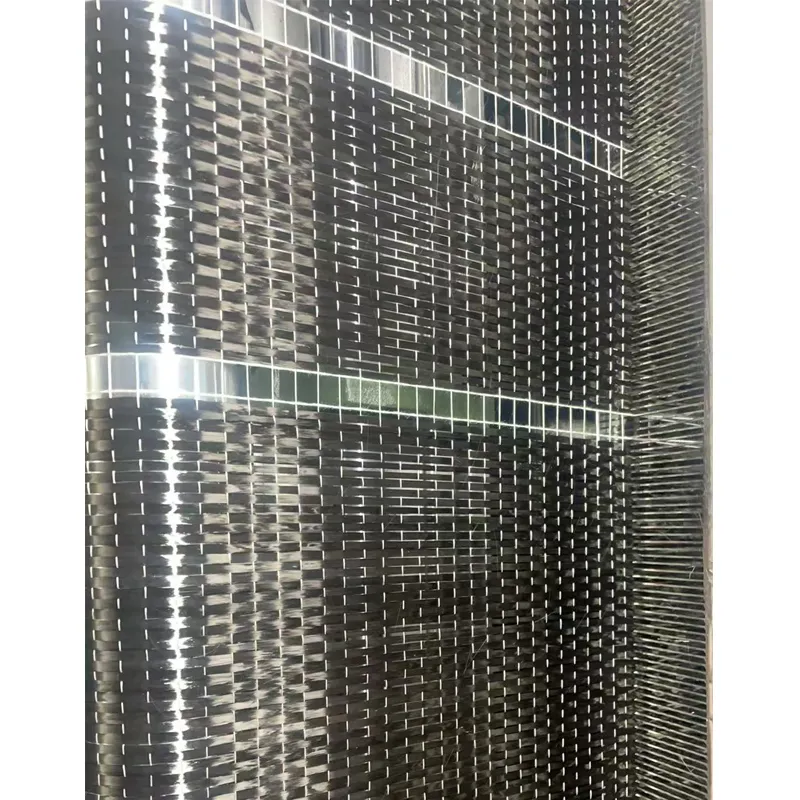

The Carbon Fiber Mesh Rapier Loom is a specialized textile weaving machine designed for producing high-strength, lightweight carbon fiber mesh fabrics. This advanced machinery utilizes a rapier weaving system, which employs rigid or flexible rapier beams to carry the weft yarn across the loom. This technology ensures precise control over the weaving process, resulting in consistent quality and high production efficiency.

Engineered for industrial-scale operations, the loom is capable of handling various carbon fiber materials, including carbon fiber yarns and composite fibers. Its robust construction and automated features make it ideal for applications requiring exceptional durability and performance, such as aerospace, automotive, and industrial filtration systems.

Key Features and Technical Specifications

- High-Speed Weaving: The loom operates at optimized speeds, significantly increasing production output while maintaining precision.

- Advanced Weft Insertion System: Utilizes a rapier mechanism for efficient and accurate weft yarn placement, reducing defects and waste.

- Large Fabric Width: Capable of producing wide mesh fabrics, catering to diverse industrial requirements.

- Computerized Control: Equipped with programmable settings for customizable weaving patterns and parameters.

- Durability and Stability: Constructed with high-quality materials to ensure long-term performance and minimal maintenance.

Industries and Applications

The Carbon Fiber Mesh Rapier Loom is widely used in industries that demand high-performance materials. Key applications include:

- Aerospace: Manufacturing lightweight, high-strength components for aircraft and spacecraft.

- Automotive: Producing carbon fiber-reinforced parts for improved vehicle performance and fuel efficiency.

- Industrial Filtration: Creating durable mesh fabrics for air and liquid filtration systems.

- Construction: Fabricating reinforcement materials for concrete and composite structures.

- Renewable Energy: Producing components for wind turbine blades and solar panel supports.

Why Choose Our Carbon Fiber Mesh Rapier Loom?

As a trusted name in the textile machinery sector, Anping Hongke Wire Mesh Machinery Factory has built a reputation for innovation and reliability. Our Carbon Fiber Mesh Rapier Loom offers several advantages:

- Superior Quality: Precision-engineered components ensure consistent fabric quality and long-term durability.

- Cost-Effective Solutions: Enhanced production efficiency reduces labor costs and material waste.

- Customizable Options: Tailored configurations to meet specific industry requirements.

- Comprehensive Support: Dedicated technical assistance and after-sales services to ensure smooth operations.

Market Demand and Industry Challenges

The demand for high-performance textiles continues to grow, driven by advancements in technology and the need for sustainable materials. However, traditional weaving methods often face challenges such as:

- Limited Production Speed: Conventional looms struggle to keep up with high-volume demands.

- Material Constraints: Difficulty in processing delicate or high-strength fibers.

- Maintenance Costs: Frequent breakdowns and repairs increase operational expenses.

Our Carbon Fiber Mesh Rapier Loom addresses these challenges by offering a reliable, high-speed solution that adapts to modern industrial needs. With its advanced technology and user-friendly design, it ensures minimal downtime and optimal productivity.

Company Expertise and Innovation

With decades of experience in textile machinery manufacturing, Anping Hongke Wire Mesh Machinery Factory has established itself as a leader in the industry. Our commitment to innovation is reflected in the development of the Carbon Fiber Mesh Rapier Loom, which combines cutting-edge technology with practical engineering.

Our research and development team continuously works on improving machine efficiency, reducing energy consumption, and enhancing user experience. This dedication to excellence has earned us a loyal customer base across the globe.

Customer Testimonials and Success Stories

Our customers consistently praise the Carbon Fiber Mesh Rapier Loom for its performance and reliability. Here are a few testimonials:

"The loom has significantly improved our production efficiency. The precision and durability are unmatched!" – Customer A

"We’ve reduced material waste by 30% since switching to this machine. Highly recommend it for any industrial textile operation." – Customer B

Usage Guidelines and Customization

To maximize the performance of the Carbon Fiber Mesh Rapier Loom, follow these guidelines:

- Pre-Operation Check: Inspect the machine for any mechanical issues and ensure all components are properly lubricated.

- Material Preparation: Use high-quality carbon fiber yarns to maintain fabric integrity and strength.

- Programmable Settings: Adjust weaving parameters based on the desired fabric specifications.

- Regular Maintenance: Schedule routine inspections and cleaning to prolong the machine’s lifespan.

We also offer customized solutions to meet your specific production needs. Contact our team to discuss tailored configurations for your industry.

Safety and Compliance

The Carbon Fiber Mesh Rapier Loom is designed with safety and environmental compliance in mind. Key features include:

- Robust Safety Mechanisms: Emergency stop functions and protective guards to prevent accidents.

- Low Energy Consumption: Energy-efficient design reduces operational costs and environmental impact.

- Compliance Certifications: Adherence to international standards for quality and safety.

Packaging and Delivery

We ensure safe and efficient delivery of the Carbon Fiber Mesh Rapier Loom through:

- Durable Packaging: Reinforced crates and protective materials to prevent damage during transit.

- Global Logistics: Partnered with reliable shipping companies for timely and secure delivery.

- Customized Shipping Options: Flexible arrangements to suit your location and schedule.

Customer Support and After-Sales Services

We provide comprehensive support to ensure your success with the Carbon Fiber Mesh Rapier Loom:

- Technical Consultation: Expert advice on machine operation and troubleshooting.

- Training Programs: On-site or remote training to enhance your team’s expertise.

- Warranty and Repairs: Extended warranty coverage and prompt service for any maintenance needs.

Our goal is to deliver exceptional value and long-term satisfaction to every client.

Contact Us for More Information

Ready to upgrade your textile production? Anping Hongke Wire Mesh Machinery Factory is here to help. Contact us today for a personalized consultation or to request a detailed product catalog.

Website: https://www.aphkmachinery.com

Email: info@aphkmachinery.com

Phone: +86-123-456-7890

Product Page: Carbon Fiber Mesh Rapier Loom Details

FAQ

Q1: What materials can the Carbon Fiber Mesh Rapier Loom process?

A: The loom is designed for carbon fiber yarns and composite fibers, suitable for high-strength applications.

Q2: How does the rapier weaving system improve efficiency?

A: The rapier mechanism ensures precise weft insertion, reducing defects and increasing production speed.

Q3: Can the machine be customized for specific needs?

A: Yes, we offer tailored configurations to meet unique industry requirements.

Q4: What support is available after purchase?

A: We provide technical training, warranty services, and 24/7 customer support.

Conclusion

The Carbon Fiber Mesh Rapier Loom from Anping Hongke Wire Mesh Machinery Factory is a game-changer for industrial textile production. With its advanced technology, durability, and customization options, it offers an ideal solution for modern manufacturing needs. Discover the future of weaving with our high-performance machinery.