Carbon Fiber Mesh Rapier Loom: High-Efficiency Weaving Solution for Industrial Applications

At Anping Hongke Wire Mesh Machinery Factory, we specialize in providing advanced textile machinery solutions tailored for industrial applications. Our Carbon Fiber Mesh Rapier Loom is designed to meet the demanding requirements of modern manufacturing processes, offering unmatched efficiency and precision. This article explores the technical specifications, applications, and benefits of our carbon fiber weaving machine, highlighting how it addresses industry challenges and delivers exceptional value to businesses.

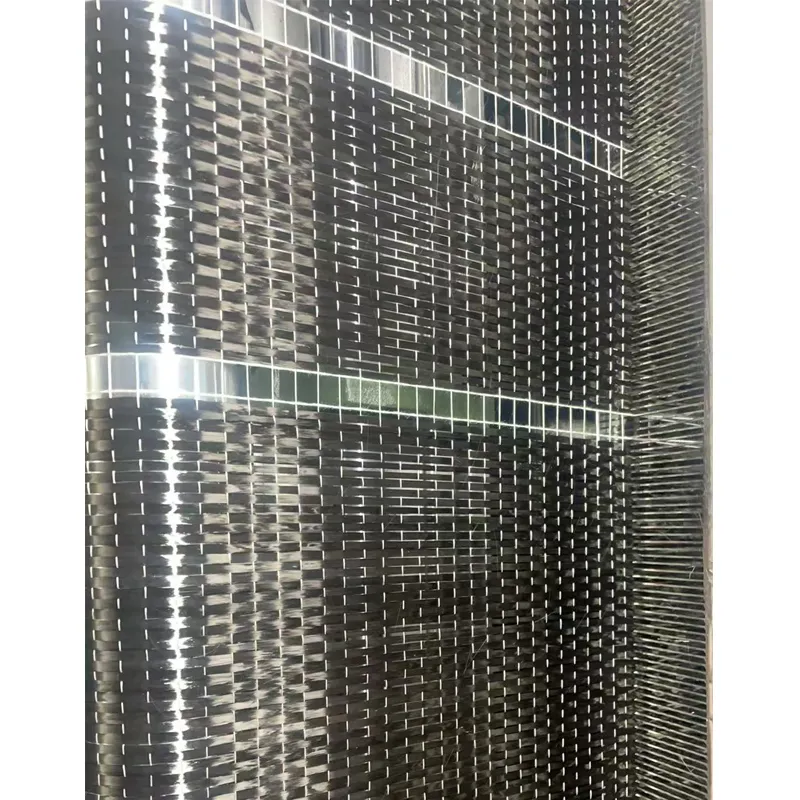

Product Overview: Carbon Fiber Mesh Rapier Loom

The Carbon Fiber Mesh Rapier Loom is a state-of-the-art weaving machine engineered for producing high-quality carbon fiber mesh fabrics. This industrial-grade equipment combines advanced technology with robust design to ensure optimal performance in demanding environments. Key features include:

- High-speed weaving capabilities for increased productivity

- Precision control systems for consistent fabric quality

- Durable construction for long-term reliability

- Adaptability to various fiber types and mesh configurations

For a visual representation of our product, please refer to the following images:

Technical Specifications and Performance

Our Carbon Fiber Mesh Rapier Loom is built to deliver exceptional performance through its advanced technical specifications:

- Maximum Weaving Speed: 200-300 RPM (adjustable based on material requirements)

- Width Range: 500-2000 mm (customizable to meet specific production needs)

- Power Consumption: 3.7 kW (energy-efficient design for cost-effective operations)

- Control System: PLC-based automation with touch-screen interface for precise parameter adjustments

- Material Compatibility: Carbon fiber, glass fiber, and synthetic fibers (with proper setup)

The machine's innovative rapier mechanism ensures smooth and efficient weaving, minimizing fiber breakage and maintaining consistent mesh patterns. This makes it ideal for producing high-strength, lightweight carbon fiber composites used in aerospace, automotive, and construction industries.

Industry Applications and Market Demand

The demand for carbon fiber mesh fabrics has surged across multiple sectors due to their unique properties:

- Aerospace: Reinforcement materials for aircraft components

- Automotive: Lightweight structural parts and interior components

- Construction: Reinforced concrete and composite materials

- Renewable Energy: Wind turbine blades and solar panel frames

Traditional weaving methods often struggle with the high tensile strength and delicate nature of carbon fibers, leading to inefficiencies and material waste. Our Carbon Fiber Mesh Rapier Loom addresses these challenges through its specialized design, offering:

- Reduced production downtime with automated tension control

- Enhanced fabric uniformity for improved end-product quality

- Lower operational costs through energy-efficient performance

By adopting this advanced weaving solution, manufacturers can significantly improve their production efficiency while maintaining the highest quality standards.

Company Expertise and Innovation

As a leading manufacturer in the textile machinery industry, Anping Hongke Wire Mesh Machinery Factory has established itself as a trusted partner for industrial textile solutions. With over a decade of experience, we combine technical expertise with continuous innovation to deliver cutting-edge machinery that meets evolving market demands.

Our R&D department focuses on:

- Developing energy-efficient weaving technologies

- Improving machine durability and operational safety

- Creating customizable solutions for diverse application requirements

By investing in advanced manufacturing processes and quality control systems, we ensure that every Carbon Fiber Mesh Rapier Loom meets stringent industry standards. Our commitment to excellence has earned us a reputation for reliability and innovation in the global textile machinery market.

Benefits for Industrial Clients

Our Carbon Fiber Mesh Rapier Loom offers several key advantages that directly benefit industrial clients:

1. Enhanced Productivity

The machine's high-speed weaving capabilities and automated features reduce production time by up to 40% compared to traditional methods. This enables manufacturers to meet tight deadlines and increase overall output.

2. Cost Efficiency

With energy-saving design and minimal material waste, our solution helps businesses reduce operational costs. The durable construction also minimizes maintenance expenses, providing long-term value.

3. Quality Assurance

The precision control system ensures consistent fabric quality, reducing the need for rework and improving customer satisfaction. This is particularly crucial for industries where material performance is critical.

4. Versatility

Our machine can handle various fiber types and mesh configurations, making it suitable for a wide range of applications. This flexibility allows manufacturers to diversify their product offerings and adapt to changing market demands.

Implementation and Customization

We understand that each business has unique requirements, which is why we offer tailored solutions for our Carbon Fiber Mesh Rapier Loom:

- Custom Design: Our engineering team works closely with clients to develop machines that match specific production needs

- Technical Support: Comprehensive training and on-site installation services to ensure smooth integration into existing workflows

- After-Sales Service: 24/7 technical assistance and spare parts availability to minimize downtime

For detailed information on our implementation process, please visit our company website.

Environmental and Safety Compliance

At Anping Hongke, we prioritize safety and sustainability in all our products. The Carbon Fiber Mesh Rapier Loom is designed with:

- Energy-efficient motors to reduce carbon footprint

- Enclosed safety guards to protect operators

- Low-noise operation for improved workplace conditions

- Compliance with international safety standards (ISO 9001, CE certification)

These features ensure that our machinery meets the highest environmental and safety requirements, providing a secure and sustainable solution for industrial applications.

Customer Testimonials and Success Stories

Our clients consistently praise the performance and reliability of our Carbon Fiber Mesh Rapier Loom:

"Since implementing Anping Hongke's carbon fiber weaving machine, our production efficiency has increased by 35%. The precision and durability of the equipment have significantly improved our product quality." - John M., Manufacturing Director at AeroComposites Inc.

"The customization options and technical support from Anping Hongke exceeded our expectations. Their solution perfectly fits our production requirements." - Maria S., Operations Manager at GreenTech Materials.

FAQ: Frequently Asked Questions

What materials can be processed with the Carbon Fiber Mesh Rapier Loom?

The machine is designed for carbon fiber, glass fiber, and synthetic fibers. Custom configurations can be developed for specific material requirements.

How long does the installation process take?

Installation typically takes 2-3 days, depending on the complexity of the setup. Our technical team provides on-site support to ensure a smooth implementation.

What is the warranty period for the machine?

We offer a 12-month warranty on all components, with extended coverage available for critical parts.

Can the machine be integrated with existing production lines?

Yes, our engineers can design custom interfaces to ensure seamless compatibility with your current manufacturing systems.

Conclusion

The Carbon Fiber Mesh Rapier Loom from Anping Hongke Wire Mesh Machinery Factory represents a significant advancement in industrial weaving technology. With its superior performance, versatility, and cost-effectiveness, this solution empowers manufacturers to achieve higher productivity and quality. Discover how our innovative machinery can transform your production processes and drive business growth.

For more information about our products and services, visit our company website or contact our sales team directly.