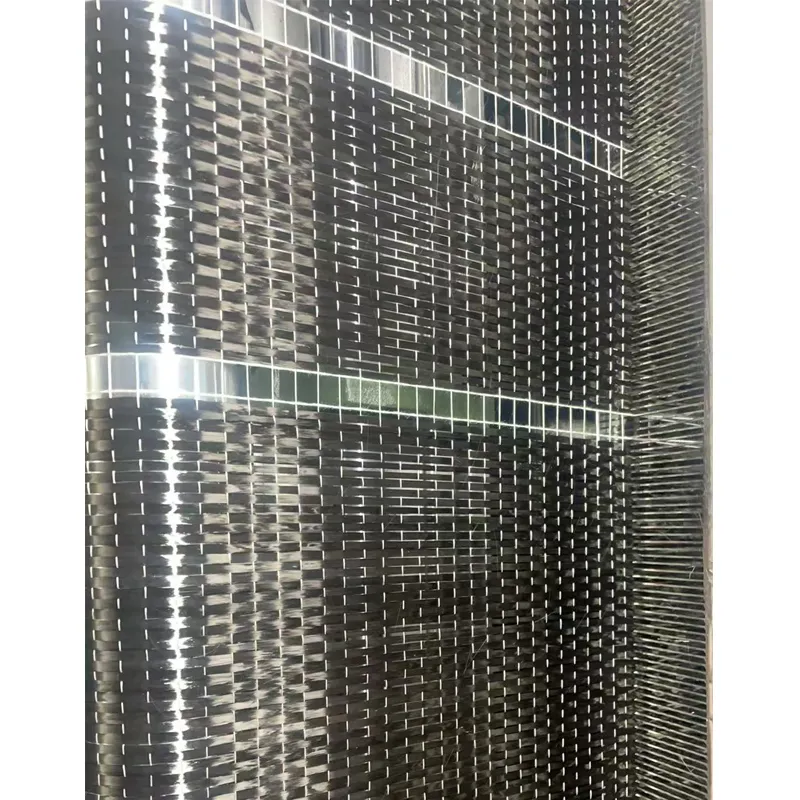

Carbon Fiber Mesh Rapier Loom: High-Efficiency Weaving Solution for Modern Industries

Discover the innovative Carbon Fiber Mesh Rapier Loom from Anping Hongke Wire Mesh Machinery Factory, designed to revolutionize textile production with precision, efficiency, and durability. This advanced machinery caters to industries demanding high-quality carbon fiber mesh, offering unmatched performance in modern manufacturing.

Product Functionality and Key Advantages

The Carbon Fiber Mesh Rapier Loom is engineered to produce high-strength, lightweight carbon fiber mesh with exceptional accuracy. Its cutting-edge technology ensures seamless weaving processes, reducing material waste and enhancing productivity. Key advantages include:

- High-Speed Operation: Achieve rapid weaving cycles without compromising quality.

- Advanced Precision: Utilizes automated tension control for consistent mesh patterns.

- Durability: Constructed with reinforced materials to withstand rigorous industrial environments.

- Flexibility: Adaptable to various mesh sizes and configurations, meeting diverse client needs.

Technical Specifications

Technical details of the Carbon Fiber Mesh Rapier Loom are tailored for industrial-grade performance:

| Parameter | Specification |

|---|---|

| Maximum Weaving Speed | 200 RPM |

| Mesh Size Range | 10mm x 10mm to 50mm x 50mm |

| Material Compatibility | Cross-plied carbon fiber, woven carbon fiber |

| Power Supply | 380V/50Hz |

| Weight | 800 kg |

Industrial Applications

This versatile loom is widely used in critical sectors requiring carbon fiber mesh, such as:

- Aerospace: Lightweight structural components and composite materials.

- Automotive: Reinforced panels and chassis parts for electric vehicles.

- Construction: High-strength reinforcement for concrete and steel structures.

- Renewable Energy: Wind turbine blades and solar panel frames.

Market Demand and Industry Challenges

The demand for carbon fiber mesh has surged due to its superior strength-to-weight ratio and corrosion resistance. However, traditional weaving methods often face challenges like high energy consumption, inconsistent product quality, and limited scalability. The Carbon Fiber Mesh Rapier Loom addresses these issues by optimizing energy efficiency and ensuring uniform mesh production, making it a game-changer for manufacturers.

Company Background and Technological Expertise

Anping Hongke Wire Mesh Machinery Factory, a leading manufacturer in the textile machinery industry, has over 15 years of experience in developing advanced weaving solutions. The company's commitment to innovation is evident in its state-of-the-art R&D facilities and partnerships with global industry leaders. With a focus on quality and customer satisfaction, Anping Hongke has established itself as a trusted name in the carbon fiber mesh market.

Product Performance and Client Testimonials

Customers report significant improvements in production efficiency and cost savings after adopting the Carbon Fiber Mesh Rapier Loom. For instance, a client in the automotive sector noted a 30% reduction in material waste and a 25% increase in output. Another user in the construction industry praised the machine's reliability and ease of maintenance, highlighting its role in meeting tight project deadlines.

Usage Guidelines and Customization Services

To maximize the benefits of the Carbon Fiber Mesh Rapier Loom, follow these steps:

- Prepare the carbon fiber raw materials according to the desired mesh specifications.

- Calibrate the loom's tension and speed settings for optimal performance.

- Monitor the weaving process to ensure consistent quality and address any issues promptly.

The company offers tailored solutions, including custom mesh patterns and machine configurations, to align with specific client requirements. Contact Anping Hongke for personalized consultations.

Safety and Compliance

The Carbon Fiber Mesh Rapier Loom adheres to international safety standards, including ISO 9001 and CE certifications. Its design incorporates safety mechanisms to prevent operational hazards, ensuring a secure environment for workers. Additionally, the machine uses eco-friendly materials and energy-saving technologies, supporting sustainable manufacturing practices.

Packaging and Logistics

For bulk orders, the loom is securely packaged in reinforced wooden crates to protect against transit damage. The company provides comprehensive logistics support, including shipping options and real-time tracking. Visit product page for detailed shipping information.

Customer Support and After-Sales Services

Anping Hongke offers 24/7 technical support, on-site training, and warranty services to ensure seamless operation of the Carbon Fiber Mesh Rapier Loom. Their dedicated team is available to address any queries and provide timely assistance, ensuring minimal downtime for clients.

Contact Us

Ready to elevate your manufacturing capabilities? Reach out to Anping Hongke Wire Mesh Machinery Factory for more information or to place an order. Contact us at sales@aphkmachinery.com or call +86-312-561-8888.

Conclusion

The Carbon Fiber Mesh Rapier Loom by Anping Hongke is a reliable solution for modern industries seeking efficiency, precision, and cost-effectiveness. Discover how this advanced machinery can transform your production processes. Visit our product page today.

Frequently Asked Questions

Q1: What is the maximum mesh size the loom can produce?

A: The loom supports mesh sizes ranging from 10mm x 10mm to 50mm x 50mm, catering to diverse applications.

Q2: Does Anping Hongke provide installation support?

A: Yes, our team offers on-site installation and training to ensure smooth operation of the machinery.

Q3: What certifications does the loom have?

A: The loom is certified under ISO 9001 and CE standards, ensuring compliance with global safety and quality requirements.