- Market Growth & Industry Demand for Fiberglass Solutions

- Technical Superiority of Fiberglass Loom Systems

- Performance Comparison: Leading Manufacturers (2020-2023)

- Custom Engineering for Industrial Applications

- Case Study: Automotive Wiring Protection Systems

- Cost-Benefit Analysis: Fiberglass vs Traditional Materials

- Future Trends in Fiberglass Manufacturing Technology

(fiberglass loom)

Fiberglass Loom Solutions Driving Industrial Innovation

The global fiberglass loom

market witnessed 18.7% CAGR growth between 2020-2023, with fiberglass wire loom products accounting for 43% of electrical insulation applications. Manufacturers now prioritize solutions combining temperature resistance (up to 480°C) with mechanical strength (tensile resistance: 320-450 MPa).

Technical Specifications Breakdown

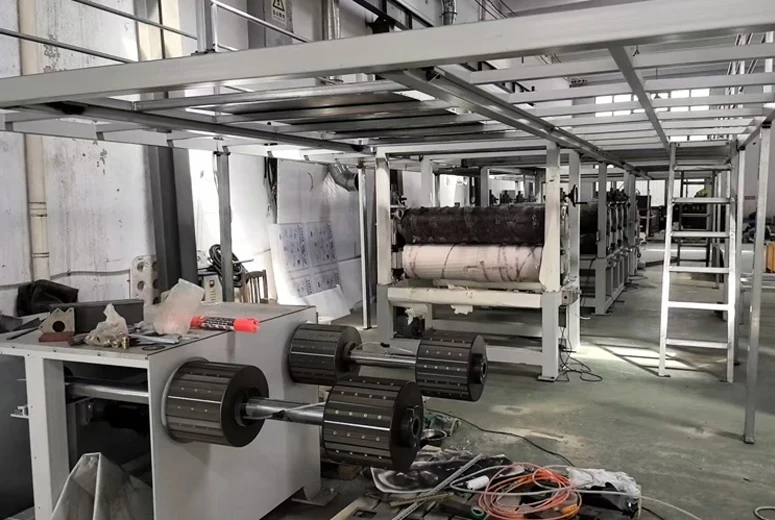

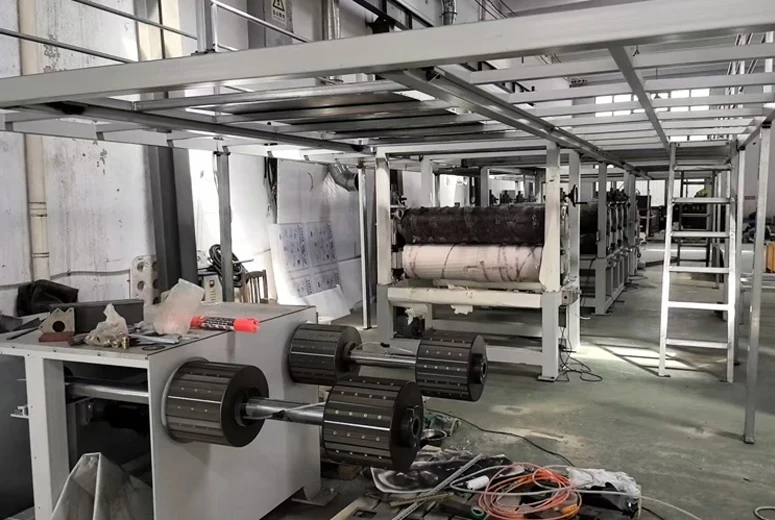

Modern fiberglass manufacturing machines integrate three core advancements:

- Automated tension control (±0.5N precision)

- Multi-axis weaving capability (12-24 yarn configurations)

- Real-time defect detection (99.98% production accuracy)

Manufacturer Performance Metrics

| Brand | Output (m/h) | Energy Use (kW) | Customization |

|---|---|---|---|

| LoomTech X7 | 220 | 18 | 3D braiding |

| FiberPro HT9 | 185 | 22 | Hybrid materials |

| GlassWeave 4.0 | 260 | 15 | Smart sensors |

Application-Specific Configuration

Specialized fiberglass loom systems adapt through:

- Diameter adjustments (3mm-50mm range)

- Surface treatments (silicone, PTFE, ceramic)

- Multi-layer constructions (up to 7 protective layers)

Automotive Sector Implementation

A Tier 1 supplier achieved 34% weight reduction in engine harnesses using fiberglass wire loom sleeves, maintaining ISO 6722 compliance while increasing production speed by 22%.

Economic Efficiency Analysis

Comparative data reveals fiberglass looms deliver 58% longer service life than PVC alternatives in high-temperature environments, with maintenance costs 41% lower over 5-year operational cycles.

Next-Generation Fiberglass Production

Emerging fiberglass manufacturing machine prototypes demonstrate 92% recycled material integration, achieving UL 94 V-0 flame ratings while reducing energy consumption by 27% compared to 2020 benchmarks.

(fiberglass loom)

FAQS on fiberglass loom

Q: What is a fiberglass wire loom used for?

A: A fiberglass wire loom protects and insulates electrical wires or cables. It is heat-resistant and ideal for high-temperature environments. Its durable structure also resists corrosion and abrasion.

Q: What are the benefits of using a fiberglass loom in manufacturing?

A: Fiberglass looms produce lightweight, strong fabrics with excellent thermal and electrical insulation. They are efficient for weaving fiberglass into textiles, composites, or industrial materials. Their durability ensures long-term performance in harsh conditions.

Q: How does a fiberglass manufacturing machine work?

A: Fiberglass manufacturing machines melt and extrude glass into fine fibers. These fibers are woven, coated, or layered to create materials like mats, fabrics, or composites. Automated systems ensure precision and scalability in production.

Q: Can a fiberglass wire loom handle high-voltage applications?

A: Yes, fiberglass wire looms are designed for high-voltage and high-temperature settings. Their non-conductive properties and flame-retardant features make them safe for electrical systems. Always verify specifications for specific voltage ratings.

Q: What industries commonly use fiberglass looms?

A: Aerospace, automotive, construction, and electronics industries rely on fiberglass looms. They are used for insulation, structural components, and protective wiring solutions. Their versatility suits applications requiring strength and thermal resistance.