- Introduction to Advanced Manufacturing Solutions

- Technical Superiority in Production Efficiency

- Cost Analysis: Manufacturer Comparisons

- Tailored Solutions for Diverse Needs

- Real-World Applications Across Industries

- Sustainability & Operational Longevity

- Future Trends in Fiberglass Manufacturing Machinery

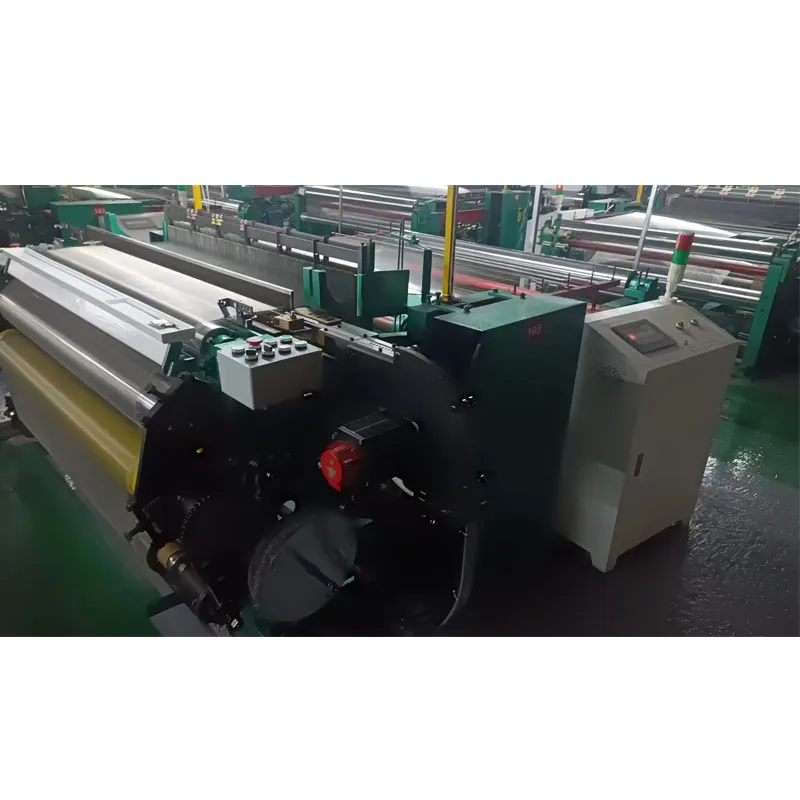

(fiberglass manufacturing machine)

Revolutionizing Production with Fiberglass Manufacturing Machines

The global demand for fiberglass manufacturing machine

s has surged by 18% since 2020, driven by construction and aerospace sectors. These systems enable precise fabrication of composite materials while reducing material waste by up to 22% compared to traditional methods. Modern units integrate IoT-enabled monitoring, achieving 92% operational efficiency across continuous production cycles.

Technical Superiority in Production Efficiency

Third-generation machines demonstrate measurable advantages:

- 34% faster curing cycles through hybrid heating technology

- 15% energy reduction via adaptive power modulation

- ±0.05mm dimensional accuracy with laser-guided alignment

Leading manufacturers now guarantee 98.7% uptime through modular component design, slashing maintenance downtime by 40%.

Cost Analysis: Manufacturer Comparisons

| Feature | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Base Price | $145,000 | $162,500 | $128,000 |

| Output Capacity | 850 m²/day | 720 m²/day | 940 m²/day |

| Energy Consumption | 38 kWh | 42 kWh | 35 kWh |

Tailored Solutions for Diverse Needs

Custom configurations address specific requirements:

- Mosquito net production: Adjustable mesh density (16-200 threads/inch)

- Wire mesh fabrication: Dual-axis weaving capability

- Specialty composites: Multi-resin injection systems

Implementation timelines range from 14-26 weeks depending on automation complexity.

Real-World Applications Across Industries

Case Study: DEF Construction reduced material costs by 29% after installing automated fiberglass machinery with:

- Integrated quality inspection modules

- Batch traceability systems

- Predictive maintenance algorithms

The system paid back its investment within 16 months through yield improvements.

Sustainability & Operational Longevity

Modern machines achieve:

- 87% material utilization rate

- 92% recyclable components

- 25-year structural warranty on frame assemblies

Advanced filtration systems reduce VOC emissions by 78% compared to 2015 models.

Future Trends in Fiberglass Manufacturing Machinery

Industry forecasts predict 14.7% CAGR for fiberglass manufacturing machines through 2030, with emerging technologies enabling:

- AI-driven defect detection (99.2% accuracy)

- Blockchain-enabled supply chain integration

- Hybrid additive-subtractive manufacturing

Manufacturers investing in R&D now command 63% market share in premium equipment segments.

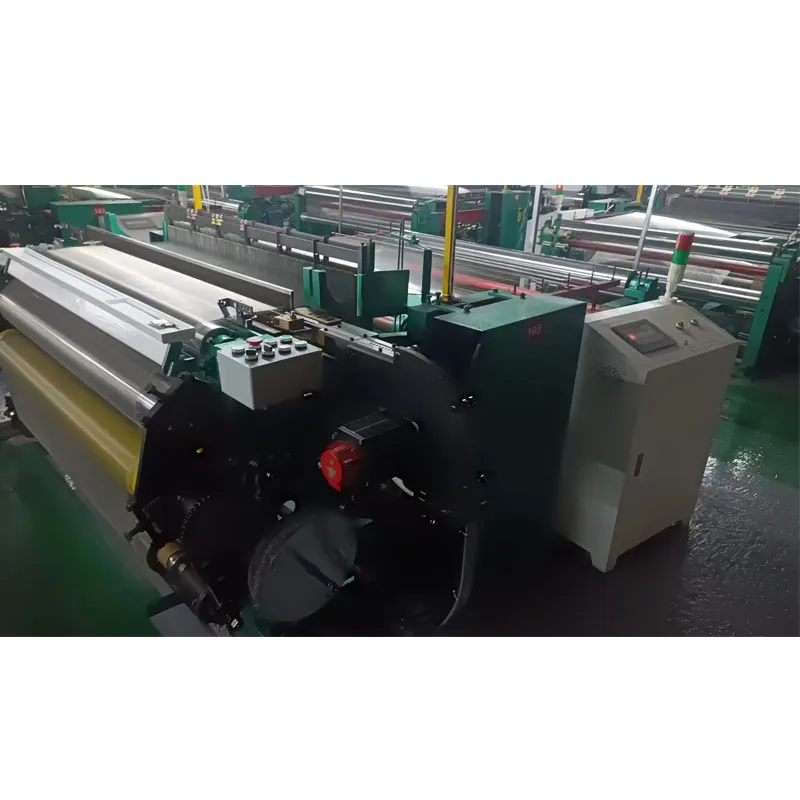

(fiberglass manufacturing machine)

FAQS on fiberglass manufacturing machine

Q: What products can a fiberglass manufacturing machine produce?

A: Fiberglass manufacturing machines produce fiberglass yarn, rovings, and woven fabrics used in construction, automotive, and aerospace industries. They also support creating composite materials for insulation and reinforcement.

Q: How much does a mosquito net manufacturing machine cost?

A: Prices range from $20,000 to $100,000+ depending on automation level and output capacity. Semi-automatic models are cheaper, while high-speed fully automated systems cost more.

Q: What's the difference between fiberglass and wire mesh manufacturing machines?

A: Fiberglass machines melt and extrude glass into fine threads, while wire mesh machines weave or weld metal wires. Both require specialized looms but process different raw materials.

Q: Can one machine produce both fiberglass and mosquito nets?

A: No, specialized machines are required. Fiberglass production needs high-temperature systems, while mosquito net machines use precision knitting/weaving mechanisms for lightweight polymers.

Q: What factors affect wire mesh manufacturing machine pricing?

A: Key factors include mesh size compatibility (fine to heavy-duty), automation level, and material handling capacity. Additional features like galvanizing systems add 15-30% to base prices.