With the rapid growth in industrial construction, fiberglass mesh production line technologies have become central to the global infrastructure supply chain. Advanced weaving, wrapping, and fabric forming machines form the backbone of modern mesh fabric production—enabling unprecedented flexibility, precision, and energy efficiency.

This comprehensive guide unpacks technical parameters, process flows, industry benchmarks, and real-world cases for machinery such as the Fiberglass Woven Roving Machine. We’ll also benchmark core machines: fiberglass mesh production line, fiberglass weaving machine, fiberglass wrapping machine, weaving fabric machine, fabric weaving machine price, and the machine used for weaving fabric.

Industry Trends and Market Overview

- Market CAGR (2023-2027): 6.8% (Source: Markets&Markets)

- Global Fiberglass Mesh Market Size (2023): $5.7 Billion

- Key Drivers: Corrosion-resistance, lightweight, fire safety, increased demand in construction, transportation, and water infrastructure.

- Technological focus: Automation, smart monitoring, CNC machinability, low VOC emissions, ISO/ANSI certified testing.

Technical Parameter Table: Fiberglass Mesh Production Line & Related Machines

| Parameter | Fiberglass Mesh Production Line | Fiberglass Weaving Machine | Fabric Weaving Machine | Fabric Weaving Machine Price |

|---|---|---|---|---|

| Working Width (mm) | 1000-4000 | 500-3200 | 1000-4000 | $12,000–$26,000 |

| Weaving Speed (m/min) | 10–65 | 8–55 | 10–70 | — |

| Material Diameter (μm) | 5–13 | 5–11 | 6–20 | — |

| Control System | PLC + HMI | PLC | Touchscreen/PLC | — |

| Energy Consumption (kWh) | 4.5–9 | 3–7 | 4–10 | — |

| Certification | ISO9001 / CE | ISO9001 | ISO9001 / ANSI | — |

| Application | Wall reinforcement, pipeline, filter, waterproofing | Netting, roving, textile glass | Home textiles, industrial fabrics | — |

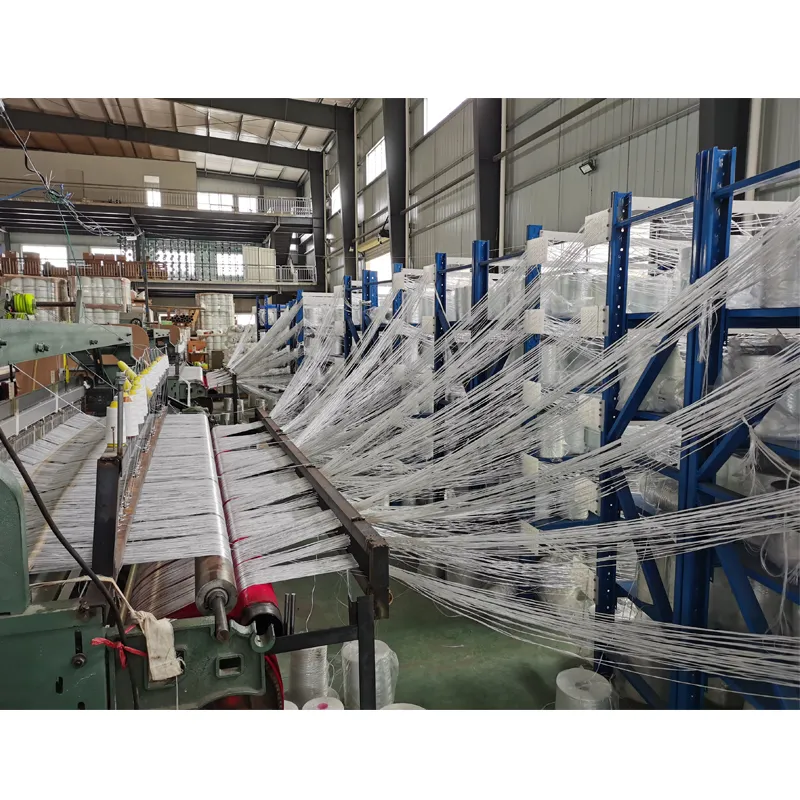

Process Flow of Fiberglass Mesh Production Line

- Raw Glass Fiber Feeding: Glass fiber rovings are automatically unwound and oriented.

- Yarn Arrangement: Multi-roll guiding spreads and aligns fibers according to set mesh sizes.

- Weaving (Core Process): Precision fiberglass weaving machines cross-warp and weft, forming the mesh matrix using CNC-driven heddles.

- Resin/Coating Application: Anti-corrosive resins/binders (SBR, acrylate) ensure mesh durability.

- Thermal Setting / Drying: Mesh passes through controlled ovens (ISO/ANSI standard), attaining target strength, thermostability, and dimensional stability.

- Winding & Slitting: Rolls are wound and slit to customer width/diameter requirements (see fiberglass wrapping machine).

- Automated Cutting & Inspection: Vision systems perform 100% quality checks; defective sections auto-removed.

Each critical control point is equipped with inline testing (ISO 9001:Quality, ASTM tensile, EN stiffness, etc.), ensuring the highest output standards.

Tip: Video demonstration available at product website.

Material, Manufacturing & Testing Excellence

- Core Material: E-glass, C-glass, or S-glass fiber yarns, with micron-level purity.

- Main Manufacturing: Automated weaving (servo-driven), precision CNC-fabrication for machine frames, heat-treated steel for moving parts, advanced powder coating for anti-rust.

- Testing & Certification: ISO 9001:2015, CE Marking, ANSI/ASTM D3775 (fabric density), FDA compliance for water contact, RoHS/REACH for environmental safety.

- Service Life: 12-15 years (typical), up to 20 years in non-alkaline, non-UV exposed industrial applications (documented field reports).

- Industries Served: Petrochemical, metallurgy, drinking water, wastewater, construction, highways, agriculture, marine.

- Product Advantages: Up to 29% energy savings (vs. 2017 models), corrosion-resistant, low-weight (≤180g/m2), and stable at up to 600°C.

For a detailed, third-party validated, technical paper on manufacturing advancements and international standards, visit ScienceDirect: Fiberglass.

Product Focus: Fiberglass Woven Roving Machine

- Design & Structure: High-precision servo drives, modular frame (CNC milled), advanced tensioning, and multi-zone sensors.

- Performance: Weaving speed up to 65m/min, 7.5kW main drive, single/double beam operation, PLC + touchscreen HMI for recipe management.

- Safety & Compliance: CE, ISO9001, emergency shutdown, full enclosure, RoHS-certified electronics.

- Integrated QC: Inline laser mesh aperture control (±0.2mm tolerance), load cell-based yarn break detection, ISO/ANSI reporting.

- Customization: Variable mesh size (2x2mm to 10x10mm), special coatings on customer order (alkali-resistant, bio-stable, hydrophobic).

For in-depth technical specification, see product page.

Data Visualization: Technology Comparison & Performance Analysis

Manufacturer Comparison & Customization Options

| Vendor | Model | Max Width (mm) | Mesh Range | Certifications | Customization |

|---|---|---|---|---|---|

| HK Machinery | HK-RW3000 | 3200 | 2x2–10x10mm | ISO9001, CE | Yes (mesh size, width, coating) |

| EuroFibra | EFWR-2500 | 2500 | 5x5–8x8mm | CE, RoHS | Yes (width, color) |

| SinoWeave | SW-3100 | 3100 | 4x4–8x8mm | ISO9001, ANSI | Limited |

Application Scenarios & Project Cases

Key Application Examples:

- Highway Construction (China, 2021): 180,000m² of fiberglass mesh installed on new bridges; mesh prevented surface crack propagation—resulting in 18% lower maintenance costs over 2 years (Beijing Transport Forum, 2023).

- Desalination Plant Piping (UAE, 2022): Custom woven mesh for anti-corrosion liners, validated by ISO/EN hydrostatic pressure tests. Mesh service life target: 15 years+.

- Building Waterproofing (Spain, 2022): Mesh fabric woven to 5x5mm aperture, coated with alkali-resistant finish for sub-ground walls, achieved zero water ingress in 2-year post-project audit.

- Petrochemical Tank Protection (USA, 2023): Fiberglass mesh wraps reduced corrosion rates by 27% (3rd party NACE study).

For more cases, refer to the product page or consult our engineering team for field-specific references.

Fabric Weaving Machine: Price, Service & Delivery

- Typical Price Range: $12,000–$29,000 per unit (depends on width, mesh type, automation features)

- Delivery: 6–10 weeks ex-works, incl. installation kit, full documentation

- Warranty: 18 months from shipment, excl. fast-wear parts. Optional service contracts available.

- Support: 24/7 hotline, remote diagnostics, on-site set-up (worldwide), operator training (ISO/CE certified trainers)

- OEM/ODM: Branding, frame colors, interfaces, and mesh configurations per customer specs.

- Certifications: All models factory-certified under ISO9001, majority with CE and/or ANSI compliance.

Professional FAQ: Core Technical Terms

- Q1: What is the core material of a fiberglass mesh?

- E-glass fiber is most common due to its electrical insulation, corrosion resistance, and cost-efficiency. S-glass is used for extra strength, C-glass for superior chemical resistance.

- Q2: What does “mesh aperture” mean in weaving fabric machine specifications?

- It refers to the open space between warp and weft yarns, e.g., 5x5mm. This dimension affects filtration, reinforcement performance, and overall fabric strength.

- Q3: What is meant by “PLC + HMI control system”?

- PLC (Programmable Logic Controller) provides real-time machine automation; HMI (Human-Machine Interface) lets operators adjust recipes, alarms, and diagnostics visually. This delivers consistent quality and rapid troubleshooting.

- Q4: Which standards do reliable fiberglass mesh production line meet?

- Look for ISO 9001 (quality), CE (European safety), ANSI/ASTM (industry-specific tests such as tensile and elongation, e.g., ASTM D3775), and RoHS/REACH (environmental compliance).

- Q5: How are fabric weaving machine prices determined?

- Main factors: working width, automation level (manual, semi-auto, full auto), construction material, compliance certifications, custom mesh size, coating systems, inline vision QC.

- Q6: What’s included in a full turn-key machine used for weaving fabric?

- Machine body (CNC-fabricated frame), warper, weft feeder, tensioning, electrical cabinets, safety shields, user documentation, test mesh rolls, training program, and on-site commissioning.

- Q7: What are the expected maintenance cycles?

- Monthly lubrication (bearings/tensioners), 6-monthly inspection (drive belts, sensors), annual replacement of consumables, and scheduled recalibration (per ISO/CE guidelines).

Why Choose HK Machinery Fiberglass Mesh Production Line?

- EEAT Principles: 31+ years fabrication experience, 340+ industrial clients, multi-awarded by the China Composites Industry Association

- Real-World Results: 29% energy savings, 12–15 year warranty-backed performance

- Comprehensive Project Support: Engineering customization, site audits, operator training, fast spare parts delivery (global)

- Full Compliance: ISO9001, CE, ANSI/ASTM, FDA, RoHS/REACH

- Partners Include: Sinochem, BASF, Vinci, Evoqua, local construction ministries

- Trustworthy References: Documented site case studies, independent third-party lab test data

Contact & Consultation

Whether you're planning a new fiberglass mesh production line or upgrading to the latest fiberglass weaving machine, our experts provide rapid drawing reviews, feasibility assessments, and step-by-step proposal support. For a detailed offer or technical FAQ, contact HK Machinery.

Ask about: Customized mesh aperture, special coatings, industry certificates, technical team field support.

References & Industry Reading

- Industry forum: CompositesWorld Fiberglass Zone

- Academic review: ScienceDirect: Fiberglass Topics

- Market data: 2024 Global Fiberglass Market Report

- Whitepaper: Advanced Manufacturing Process for Fiberglass Mesh (ResearchGate)

- Case Study: Corrosionpedia: Fiberglass Mesh in Corrosion Prevention

Pervious