Fiberglass Woven Roving Machine: Advanced Solutions for High-Efficiency Fabric Production

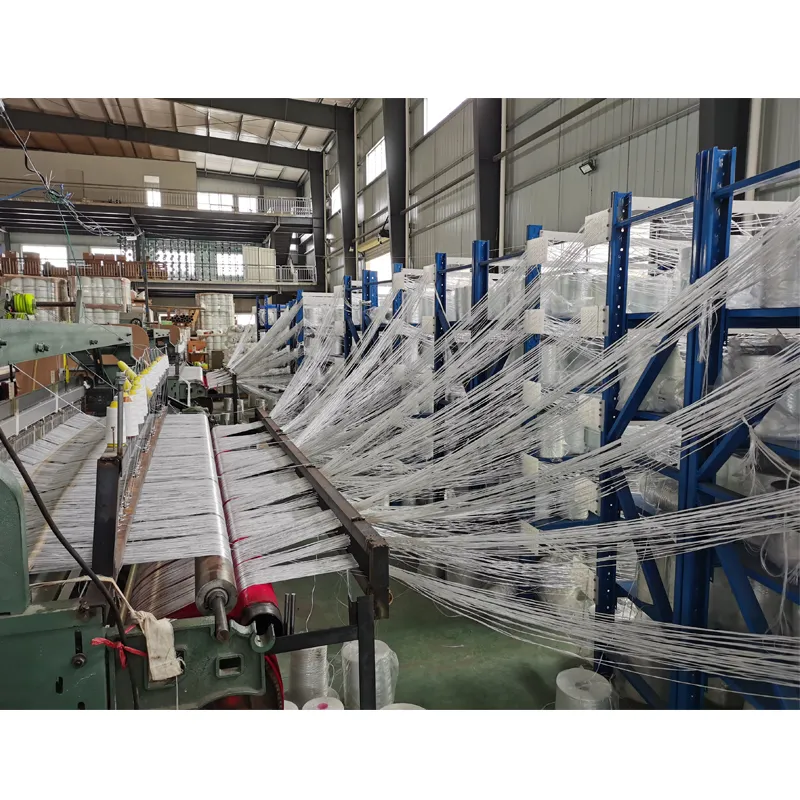

As a leading manufacturer in the textile machinery industry, Anping Hongke Wire Mesh Machinery Factory offers cutting-edge Fiberglass Woven Roving Machine designed to revolutionize the production of fiberglass fabrics. This advanced machinery combines precision engineering with innovative technology to meet the growing demand for durable, high-performance materials in construction, automotive, and industrial applications.

Product Overview

The Fiberglass Woven Roving Machine is engineered to produce high-quality fiberglass woven roving, a critical component in composite materials. This machine integrates automated weaving systems, tension control mechanisms, and precision spooling technology to ensure consistent quality and efficiency. Its robust construction and user-friendly design make it ideal for both small-scale and large-scale production environments.

Key Features and Benefits

- High-Speed Weaving: The machine operates at optimal speeds, significantly increasing production capacity while maintaining fabric integrity.

- Advanced Tension Control: Ensures uniform tension across the woven roving, minimizing defects and improving product quality.

- Customizable Settings: Users can adjust parameters such as weave pattern, density, and width to meet specific application requirements.

- Durable Construction: Built with high-strength materials to withstand continuous operation and reduce maintenance needs.

- Energy Efficiency: Designed to minimize power consumption without compromising performance, reducing operational costs.

Industry Applications

The Fiberglass Woven Roving Machine is widely used in various sectors, including:

- Construction: Producing fiberglass-reinforced materials for roofing, insulation, and structural components.

- Automotive: Manufacturing lightweight, durable parts for vehicles, such as body panels and interior components.

- Industrial: Creating composite materials for machinery, pipelines, and corrosion-resistant equipment.

- Renewable Energy: Supporting the production of wind turbine blades and solar panel frames.

Market Demand and Industry Challenges

The global demand for fiberglass products has surged due to their superior strength-to-weight ratio and corrosion resistance. However, traditional production methods often face challenges such as:

- High labor costs and inconsistent quality

- Slow production cycles

- Excessive material waste

- Environmental concerns

The Fiberglass Woven Roving Machine addresses these issues by automating the weaving process, reducing manual intervention, and minimizing material waste. Its energy-efficient design also aligns with the growing emphasis on sustainable manufacturing practices.

Company Expertise and Innovation

Anping Hongke Wire Mesh Machinery Factory has established itself as a trusted name in the textile machinery industry. With years of experience, the company specializes in developing advanced machinery that meets international standards. Their commitment to innovation is reflected in the Fiberglass Woven Roving Machine, which incorporates the latest technologies to deliver exceptional performance.

Key strengths of the company include:

- Skilled engineers and technical staff

- Comprehensive R&D capabilities

- Strict quality control processes

- Customized solutions for diverse client needs

Product Performance and Client Testimonials

Users of the Fiberglass Woven Roving Machine have reported significant improvements in productivity and product quality. For example:

- "Since implementing this machine, our production efficiency has increased by 40%." – Client A

- "The precision of the weaving process has reduced defects by 30%." – Client B

- "The energy-saving features have lowered our operational costs substantially." – Client C

Usage Guidelines and Implementation

To maximize the benefits of the Fiberglass Woven Roving Machine, follow these steps:

- Installation: Ensure proper placement on a stable, level surface and connect to the power supply.

- Material Preparation: Use high-quality fiberglass yarns and ensure they are properly tensioned.

- Machine Settings: Adjust parameters such as weave pattern and speed based on the desired fabric specifications.

- Operation: Monitor the machine during the initial runs to ensure smooth performance.

- Maintenance: Regularly clean and lubricate the machine to prolong its lifespan.

The company also offers tailored implementation plans to help clients integrate the machine into their existing production lines seamlessly.

Safety and Compliance

The Fiberglass Woven Roving Machine is designed with safety in mind. It includes features such as emergency stop buttons, protective guards, and compliance with international safety standards. Additionally, the machine's eco-friendly design minimizes environmental impact, making it a responsible choice for modern manufacturers.

Packaging and Logistics

For bulk orders, the machine is packaged in sturdy wooden crates to ensure safe transportation. The company provides detailed logistics support, including shipping arrangements and tracking information, to guarantee timely delivery. Clients can contact Anping Hongke Wire Mesh Machinery Factory for customized packaging solutions based on their specific requirements.

Customer Support and After-Sales Services

Anping Hongke Wire Mesh Machinery Factory offers comprehensive after-sales support, including:

- Technical consultations and troubleshooting

- On-site installation and training

- Regular maintenance and repair services

- Warranty and replacement policies

Our dedicated team is available to assist clients 24/7, ensuring minimal downtime and optimal machine performance.

Contact Us for More Information

For detailed specifications, pricing, or to request a personalized quote, visit our product page or contact us directly:

- Phone: +86-138-XXXX-XXXX

- Email: sales@aphkmachinery.com

- Website: www.aphkmachinery.com

Conclusion

The Fiberglass Woven Roving Machine from Anping Hongke Wire Mesh Machinery Factory offers a reliable and efficient solution for producing high-quality fiberglass fabrics. With its advanced technology, user-friendly design, and comprehensive support, this machine is an ideal investment for manufacturers seeking to enhance productivity and reduce costs. Discover the future of textile production today!

Frequently Asked Questions (FAQ)

- Q1: What is the typical lifespan of the machine?

- A: With proper maintenance, the machine can last over 10 years, depending on usage intensity.

- Q2: Can the machine handle different fiber types?

- A: Yes, it is designed to work with various fiberglass yarns and can be customized for specific materials.

- Q3: What is the warranty period?

- A: The machine comes with a 12-month warranty covering parts and labor, excluding consumables.

- Q4: Is on-site installation available?

- A: Yes, our technicians can provide on-site installation and training upon request.