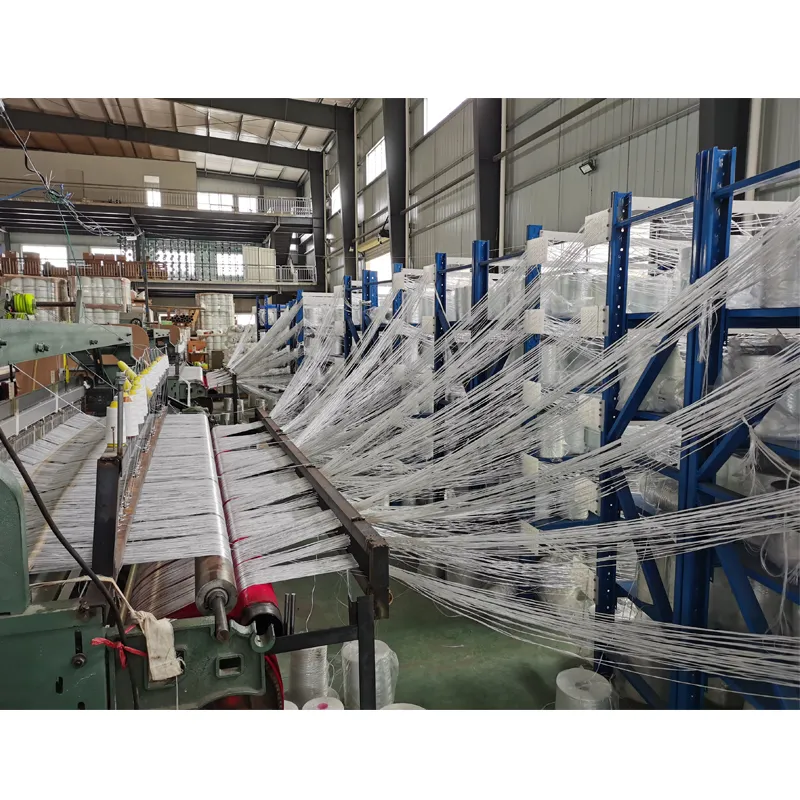

Fiberglass Woven Roving Machine: High-Efficiency Fabric Weaving Solution for Industrial Applications

Introduction

As a leading manufacturer in the fiberglass industry, Anping Hongke Wire Mesh Machinery Factory offers innovative solutions to meet the growing demand for high-quality fiberglass woven roving machines. Our advanced fiberglass woven roving machine is designed to provide efficient, reliable, and cost-effective fabric weaving solutions for industrial applications.

Product Overview

The fiberglass woven roving machine is a specialized equipment used in the production of fiberglass mesh and woven fabrics. It integrates advanced technology and precise engineering to ensure high-speed weaving with consistent quality. This machine is ideal for industries requiring durable and lightweight materials, such as construction, automotive, and marine sectors.

Key Features and Specifications

- High Efficiency: The machine is equipped with high-speed weaving mechanisms that significantly increase production output.

- Durability: Constructed with robust materials, the machine ensures long-lasting performance even under heavy usage.

- Flexibility: It supports various weaving patterns and fabric thicknesses, catering to diverse industrial requirements.

- Automation: Advanced automation features reduce manual intervention, enhancing operational efficiency and minimizing errors.

- Energy Efficiency: The machine is designed to consume less power while maintaining optimal performance, reducing overall operational costs.

Applications in Industrial Sectors

The fiberglass weaving machine is widely used in the following industries:

- Construction: For producing fiberglass mesh used in wall reinforcement and insulation.

- Automotive: In manufacturing lightweight components for vehicle interiors and exteriors.

- Marine: For creating durable materials used in boat hulls and decks.

- Electronics: In the production of circuit boards and insulation materials.

Addressing Industry Challenges

The fiberglass weaving process often faces challenges such as inconsistent quality, high production costs, and inefficiency. Our fiberglass wrapping machine is engineered to overcome these issues by providing precise control over the weaving process, ensuring uniform quality and reducing material waste. This results in significant cost savings for manufacturers.

Company Expertise and Innovation

With years of experience in the fiberglass machinery industry, Anping Hongke Wire Mesh Machinery Factory has established itself as a trusted name. Our commitment to innovation is reflected in the continuous improvement of our products, incorporating the latest technological advancements to meet evolving market demands.

Customer Testimonials

Our clients have consistently praised the performance of our fiberglass mesh production line. One customer stated, "The efficiency and reliability of the machine have transformed our production process, leading to a 30% increase in output." Another noted, "The quality of the woven fabrics produced by this machine is unmatched, significantly enhancing our product value."

Usage Guide and Customization

Our fabric weaving machine comes with detailed user manuals and technical support to ensure seamless integration into your production workflow. We also offer customization options to tailor the machine to your specific requirements, ensuring optimal performance and productivity.

Safety and Compliance

Safety is a top priority in our product design. The fiberglass woven roving machine adheres to international safety standards, ensuring a secure working environment. Additionally, our machines are manufactured using eco-friendly materials and processes, aligning with global sustainability initiatives.

Packaging and Delivery

We provide durable packaging solutions to protect the machine during transportation. Our logistics partners ensure timely delivery, regardless of the order size. For bulk purchases, we offer customized packaging options to meet your specific needs.

Support and After-Sales Services

At Anping Hongke Wire Mesh Machinery Factory, we are dedicated to providing comprehensive support. Our team offers 24/7 technical assistance, on-site training, and product customization services to ensure your satisfaction. We also provide warranty and maintenance packages to guarantee long-term reliability.

Contact Us

For more information about our fiberglass woven roving machine or to place an order, please visit our company website or contact us directly at sales@aphkmachinery.com. Explore our product page to discover how our solutions can benefit your business.

Conclusion

The fiberglass woven roving machine from Anping Hongke Wire Mesh Machinery Factory offers an efficient, reliable, and cost-effective solution for industrial fabric weaving. With its advanced features and exceptional performance, this machine is a valuable asset for any manufacturer looking to enhance productivity and quality.

Frequently Asked Questions (FAQ)

What is the primary function of a fiberglass woven roving machine?

The fiberglass woven roving machine is designed to produce high-quality fiberglass mesh and woven fabrics, which are used in various industrial applications. It ensures consistent quality and efficient production.

How does the machine improve production efficiency?

The machine's advanced automation and high-speed weaving mechanisms significantly increase production output while maintaining optimal quality. This reduces downtime and enhances overall efficiency.

What industries benefit from using this machine?

The fiberglass weaving machine is ideal for the construction, automotive, marine, and electronics industries, where durable and lightweight materials are required.

Is the machine easy to maintain?

Yes, the machine is designed with user-friendly maintenance features. Regular upkeep is straightforward, and our technical support team is available to assist with any issues.

Can the machine be customized to meet specific requirements?

Yes, we offer customization options to tailor the machine to your unique production needs, ensuring optimal performance and productivity.