Fiberglass Woven Roving Machine: Precision, Efficiency, and Innovation in Textile Manufacturing

The Fiberglass Woven Roving Machine represents a cutting-edge solution in the textile and composite materials industry. Designed to meet the demands of modern manufacturing, this machine combines high-speed weaving technology with advanced engineering to produce fiberglass square cloth with exceptional precision and durability. Developed by Anping Hongke Wire Mesh Machinery Factory, a leading manufacturer in China, the machine is engineered to deliver consistent quality across diverse applications.

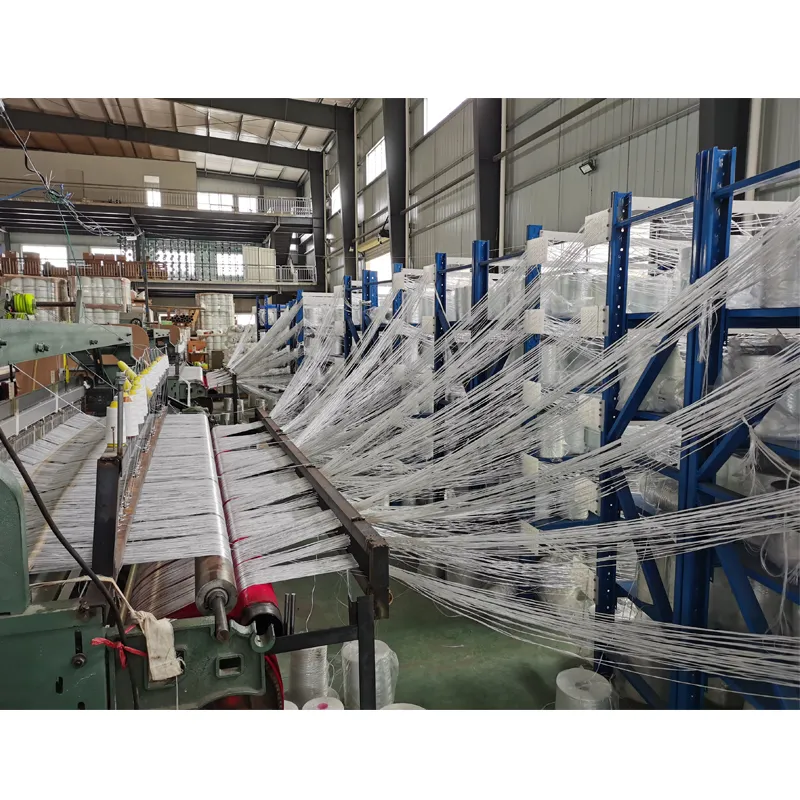

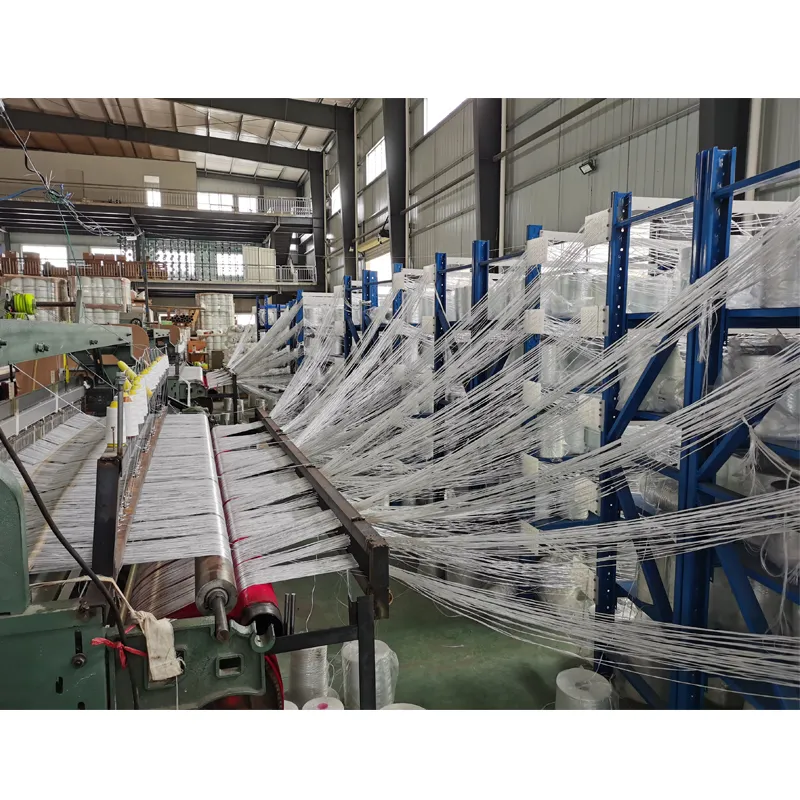

Product image of the Fiberglass Woven Roving Machine showcasing its robust design and advanced features.

Key Features and Advantages

The Fiberglass Woven Roving Machine is distinguished by its high precision, production efficiency, and stable performance. Below are the core advantages of this machine:

- High Precision: The machine ensures accurate control of warp and weft thread spacing and density, resulting in uniform grid structures and dimensional accuracy. This is critical for applications requiring strict tolerances, such as aerospace and electronics.

- High Production Efficiency: With speeds up to 175 picks per minute, the machine significantly reduces production time, making it ideal for large-scale manufacturing. This efficiency lowers costs while maintaining high-quality output.

- Stable Performance: Constructed with high-quality materials and advanced manufacturing processes, the machine operates reliably over extended periods. Its robust design minimizes downtime and ensures consistent product quality.

- Wide Applicability: The machine can produce fiberglass square cloth in various specifications, from lightweight materials for electronic packaging to heavy-duty fabrics for construction reinforcement.

Close-up of the machine's components, highlighting its durable construction and advanced engineering.

Technical Specifications

The Fiberglass Woven Roving Machine is available in multiple models, each tailored to specific production requirements. Below is a detailed specification table for the 255 Type and High-Speed Models:

| Product Specifications | |

|---|---|

| Product Width | 2000mm |

| Machine Size (255 Type) | L4m × W1.75m × H1.45m |

| Power (255 Type) | 1.5 KW |

| Weight (255 Type) | 1.7 tons |

| Speed (255 Type) | 125-135 times per minute |

| Machine Size (High-Speed Models) | L4.6m × W1.9m × H1.45m |

| Power (High-Speed Models) | 4 KW |

| Weight (High-Speed Models) | 3.2 tons |

| Speed (High-Speed Models) | 150-175 times per minute |

Diagram illustrating the operational process of the Fiberglass Woven Roving Machine.

Applications in Diverse Industries

The versatility of the Fiberglass Woven Roving Machine makes it suitable for a wide range of applications:

- Construction: Reinforcement materials for concrete and structural components.

- Automotive: Lightweight, durable fabrics for vehicle interiors and exteriors.

- Electronics: Insulating materials for circuit boards and packaging.

- Marine: Corrosion-resistant materials for boat hulls and components.

- Aerospace: High-strength fabrics for aircraft interiors and composite structures.

Examples of industrial applications where the Fiberglass Woven Roving Machine excels.

Company Background: Anping Hongke Wire Mesh Machinery Factory

Anping Hongke Wire Mesh Machinery Factory is a renowned manufacturer specializing in textile and wire mesh machinery. With decades of experience, the company has established itself as a leader in providing innovative solutions for the fiberglass and composite materials industry. Their product line includes fiberglass mesh production lines and fiberglass weaving machines, designed to meet the evolving needs of global markets.

As a trusted name in the industry, Anping Hongke adheres to strict quality control standards, ensuring that every machine is built to deliver optimal performance and longevity. The company's commitment to innovation and customer satisfaction has earned it a loyal clientele across multiple sectors.

Why Choose This Fiberglass Woven Roving Machine?

Investing in the Fiberglass Woven Roving Machine offers several advantages:

- Cost-Effectiveness: High production efficiency and low maintenance costs reduce overall expenses.

- Scalability: The machine's adaptability to different specifications allows for flexible production scaling.

- Reliability: Advanced engineering ensures long-term stability and minimal downtime.

- Compliance: The machine aligns with international standards for quality and safety, as outlined by organizations like NIST (National Institute of Standards and Technology).

For more information about fiberglass weaving machine solutions, visit the official Anping Hongke Wire Mesh Machinery Factory website.

Conclusion

The Fiberglass Woven Roving Machine is a testament to technological advancement in textile manufacturing. With its combination of precision, efficiency, and durability, it is an indispensable tool for industries requiring high-quality fiberglass products. Whether for construction, automotive, or aerospace applications, this machine delivers unmatched performance and reliability.

For further details on fiberglass mesh production lines or fiberglass wrapping machines, explore the offerings of Anping Hongke Wire Mesh Machinery Factory.

Authoritative Reference

While specific standards for fiberglass weaving machines may not be directly outlined by NIST, the institute plays a critical role in establishing measurement standards and technical guidelines that underpin industrial manufacturing processes. NIST's work in precision engineering and materials science ensures that technologies like the Fiberglass Woven Roving Machine meet rigorous quality and performance benchmarks.

Reference: National Institute of Standards and Technology (NIST) - https://www.nist.gov

Pervious