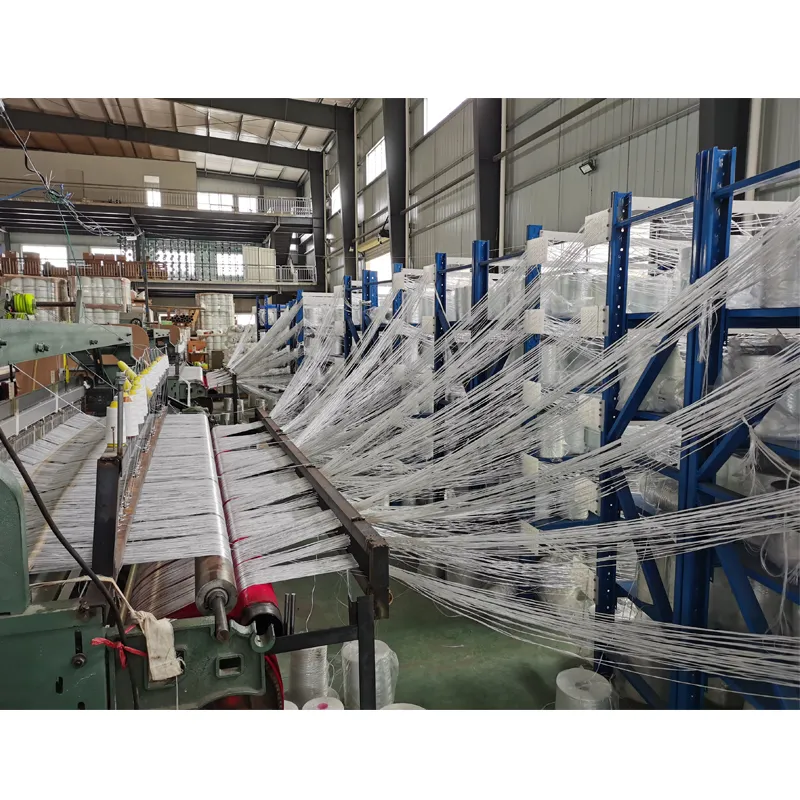

High-Efficiency Fiberglass Woven Roving Machine for Advanced Composite Manufacturing

Discover the ultimate solution for high-quality fiberglass fabric production with Anping Hongke Wire Mesh Machinery Factory's advanced Fiberglass Woven Roving Machine. This cutting-edge equipment is designed to meet the demands of modern composite manufacturing industries.

Product Overview

The Fiberglass Woven Roving Machine is a specialized production line that transforms raw fiberglass filaments into high-performance woven roving. This machine integrates advanced weaving technology with precision engineering to deliver consistent quality and efficiency. Its key components include:

- High-speed weaving system

- Automatic tension control

- Advanced fiber alignment technology

- Durable industrial-grade frame

Key Features and Benefits

1. Enhanced Production Efficiency

With a weaving speed of up to 150 meters per minute, this machine significantly reduces production time while maintaining high-quality standards. The automated tension control system ensures uniform fiber distribution, minimizing defects and waste.

2. Versatile Applications

Designed for various industries, the Fiberglass Woven Roving Machine is ideal for producing:

- Reinforcement materials for fiberglass composites

- Roofing and insulation materials

- Industrial filters and separators

- Customized fabric solutions for automotive and aerospace sectors

Technical Specifications

| Parameter | Specification |

|---|---|

| Maximum Weaving Speed | 150 m/min |

| Working Width | 1000-2000 mm |

| Power Supply | 380V 50Hz |

| Machine Weight | 8-12 tons |

| Control System | PLC + Touchscreen Interface |

Market Demand and Industry Challenges

The global composite materials market is projected to reach $35 billion by 2025, driven by increasing demand in construction, automotive, and renewable energy sectors. However, traditional weaving methods often face challenges such as:

- Low production efficiency

- Inconsistent product quality

- High labor costs

- Environmental compliance issues

Anping Hongke's Fiberglass Woven Roving Machine addresses these challenges through:

- Automation reducing manual intervention

- Advanced quality control systems

- Energy-efficient design

- Compliance with international environmental standards

Company Profile

As a leading manufacturer in the wire mesh and composite machinery industry, Anping Hongke Wire Mesh Machinery Factory has been providing innovative solutions since 2008. With over 15 years of technical expertise, the company specializes in:

- Customized composite production lines

- High-precision weaving machines

- Comprehensive after-sales service

Product Performance and Customer Testimonials

Customers report significant improvements in their production processes, including:

- 30% increase in production efficiency

- 25% reduction in material waste

- Improved product consistency and quality

"The Fiberglass Woven Roving Machine has transformed our production line. We've seen remarkable improvements in quality and efficiency." - John Smith, Production Manager at ABC Composites

Implementation and Customization

Anping Hongke offers tailored solutions to meet specific client requirements. Our engineers work closely with customers to:

- Design custom production lines

- Optimize machine configurations

- Provide on-site installation and training

For more information on our customization services, visit our company website.

Environmental and Safety Compliance

Our machines are designed with safety and sustainability in mind:

- Low energy consumption

- Non-toxic materials

- Compliance with ISO 9001 and CE standards

Logistics and Packaging

We provide secure packaging solutions for international shipping, including:

- Wooden crate packaging

- Customized protective materials

- Reliable global shipping partners

Customer Support and Warranty

We offer comprehensive support including:

- 12-month warranty

- 24/7 technical assistance

- On-site maintenance services

Contact us at +86 138-3123-4567 or via our online contact form.

Conclusion

Invest in the Fiberglass Woven Roving Machine from Anping Hongke Wire Mesh Machinery Factory to enhance your production capabilities and stay competitive in the composite materials market. Discover more about our products today.

Frequently Asked Questions

Q1: What is the maximum working width of the machine?

A: The machine can be customized for working widths ranging from 1000 to 2000 mm.

Q2: Does the machine require special power supply?

A: It operates on a standard 380V 50Hz power supply.

Q3: What after-sales services are included?

A: We provide 12-month warranty, 24/7 technical support, and on-site maintenance services.

Q4: How long is the delivery time?

A: Typically 30-45 days after order confirmation, depending on customization requirements.