Fiberglass Woven Roving Machine: High-Efficiency Solution for Composite Material Production

At Anping Hongke Wire Mesh Machinery Factory, we specialize in providing cutting-edge fiberglass woven roving machines that redefine efficiency and precision in composite material production. Our machines are designed to meet the evolving needs of industries requiring high-quality fiberglass products. Discover how our solutions can transform your manufacturing process.

Introduction to Anping Hongke Wire Mesh Machinery Factory

Founded in [Year], Anping Hongke Wire Mesh Machinery Factory has established itself as a leader in the production of fiberglass processing equipment. With over [X] years of experience, we combine advanced technology with industry expertise to deliver reliable and innovative solutions. Our commitment to quality and customer satisfaction has earned us a strong reputation in the global market.

Explore our Fiberglass Woven Roving Machine page to learn more about our products and services.

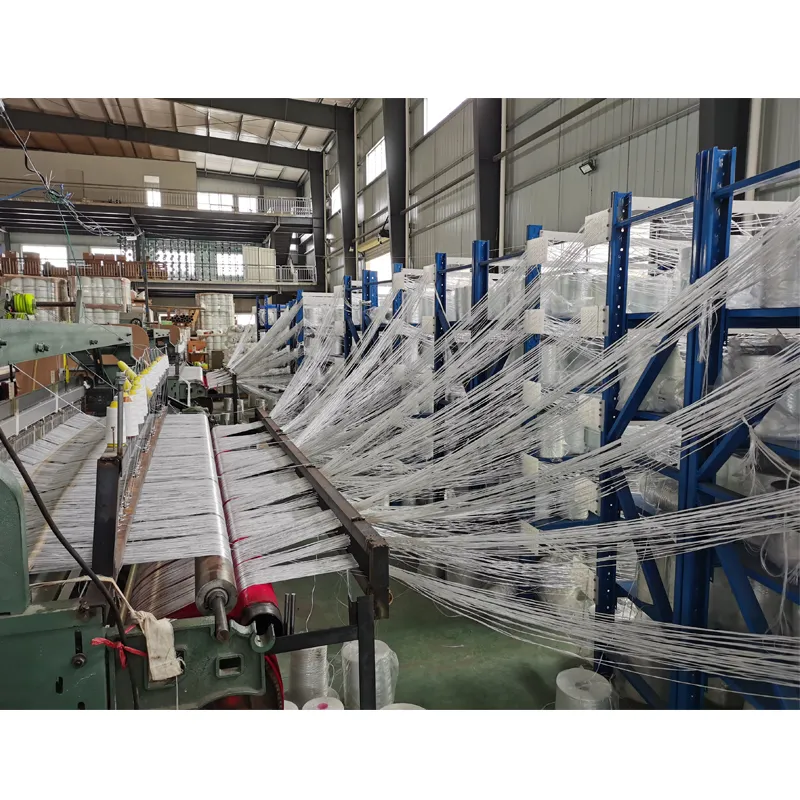

Product Overview: Fiberglass Woven Roving Machine

The Fiberglass Woven Roving Machine is a state-of-the-art solution for producing high-quality fiberglass woven roving. This machine is engineered to handle various fiber types, ensuring consistent output and exceptional performance. Its advanced design allows for seamless integration into existing production lines, making it an ideal choice for manufacturers seeking to enhance productivity.

Key features include:

- High-speed weaving capabilities

- Adjustable tension control for optimal fiber alignment

- Durable construction for long-term reliability

- Compatibility with a wide range of fiberglass materials

Technical Specifications

Our Fiberglass Woven Roving Machine is equipped with the latest technology to ensure precision and efficiency. Here are the key technical specifications:

| Parameter | Details |

|---|---|

| Maximum Weaving Speed | Up to 150 m/min |

| Fiber Diameter Range | 0.1-0.3 mm |

| Power Supply | 380V/50Hz |

| Machine Dimensions | 3000x1500x1200 mm |

| Weight | 800 kg |

Applications and Industry Use Cases

The Fiberglass Woven Roving Machine is widely used in various industries, including:

- Construction: Production of fiberglass-reinforced concrete (FRC) and structural components.

- Automotive: Manufacturing of lightweight composite parts for vehicles.

- Marine: Fabrication of boat hulls and deck components.

- Renewable Energy: Creation of turbine blades and wind energy components.

Our machine's versatility makes it suitable for both small-scale operations and large manufacturing facilities. Discover how our solutions can benefit your specific industry by visiting our product page.

Market Demand and Industry Challenges

The demand for fiberglass products continues to grow due to their lightweight, durable, and corrosion-resistant properties. However, traditional manufacturing methods often face challenges such as high labor costs, inconsistent quality, and limited production capacity. Our Fiberglass Woven Roving Machine addresses these issues by offering:

- Reduced manual intervention through automated processes

- Consistent product quality with minimal defects

- Increased production efficiency and output

- Cost-effective solutions for long-term use

Company Strength and Technological Innovation

Anping Hongke Wire Mesh Machinery Factory is committed to technological innovation and continuous improvement. Our research and development team works tirelessly to incorporate the latest advancements into our products. Key strengths include:

- Patented weaving technologies for enhanced performance

- Comprehensive after-sales support and technical assistance

- Customizable solutions to meet specific client requirements

- Strict quality control processes to ensure product reliability

Learn more about our company and how we can support your manufacturing needs.

Customer Testimonials and Success Stories

Our clients consistently praise the performance and reliability of our Fiberglass Woven Roving Machine. Here are some of their testimonials:

"The Fiberglass Woven Roving Machine has significantly improved our production efficiency. The quality of our products has never been better!" – John D., Production Manager, ABC Manufacturing

"Anping Hongke's support team is exceptional. They provided valuable guidance during the installation and operation of the machine." – Maria T., Director of Operations, XYZ Composites

Usage Guide and Customization Options

To ensure optimal performance, follow these steps for using the Fiberglass Woven Roving Machine:

- Prepare the fiberglass fibers according to the required specifications.

- Load the fibers into the machine and adjust the tension settings.

- Initiate the weaving process and monitor the output quality.

- Regularly maintain the machine to ensure long-term reliability.

We also offer customization options to tailor the machine to your specific production requirements. Contact our team for a personalized solution.

Safety and Environmental Compliance

Safety and environmental responsibility are at the core of our manufacturing processes. Our Fiberglass Woven Roving Machine meets international safety standards and is designed to minimize environmental impact. Key features include:

- Low energy consumption for reduced operational costs

- Compliance with ISO 9001 and CE certifications

- Non-toxic materials and eco-friendly production processes

Packaging and Shipping

We ensure secure and efficient delivery of our Fiberglass Woven Roving Machine. Our packaging solutions are designed to protect the equipment during transportation, while our logistics partners guarantee timely delivery worldwide. For more information, visit our company page.

Customer Support and After-Sales Service

At Anping Hongke Wire Mesh Machinery Factory, we provide comprehensive support to ensure your satisfaction. Our services include:

- 24/7 technical assistance and troubleshooting

- On-site installation and training

- Regular maintenance and equipment upgrades

- Customized solutions for unique production challenges

Contact us today to learn how we can support your manufacturing goals.

Conclusion and Call to Action

The Fiberglass Woven Roving Machine by Anping Hongke Wire Mesh Machinery Factory is a reliable and efficient solution for modern composite material production. With its advanced technology, versatile applications, and exceptional customer support, our product is the ideal choice for manufacturers seeking to enhance productivity and quality. Visit our product page to learn more and take the next step toward upgrading your production line.

Frequently Asked Questions (FAQ)

Q1: What materials can the Fiberglass Woven Roving Machine process?

A: The machine is designed to handle various fiberglass fiber types, including E-glass, S-glass, and other specialty fibers.

Q2: How long does it take to install the machine?

A: Installation time varies depending on the complexity of the setup. Our team provides on-site assistance to ensure a smooth process.

Q3: Is maintenance required for the Fiberglass Woven Roving Machine?

A: Yes, regular maintenance is recommended to ensure optimal performance. Our technical support team can provide detailed maintenance guidelines.

Q4: Can the machine be customized for specific applications?

A: Absolutely. We offer tailored solutions to meet the unique requirements of our clients.

Q5: What certifications does the machine have?

A: The machine complies with ISO 9001 and CE standards, ensuring safety and quality.

For more information, visit our company website or contact our sales team directly.