Anping Hongke Wire Mesh Machinery Factory

Global leader in advanced weaving solutions since 2002

Innovative Weaving Technology

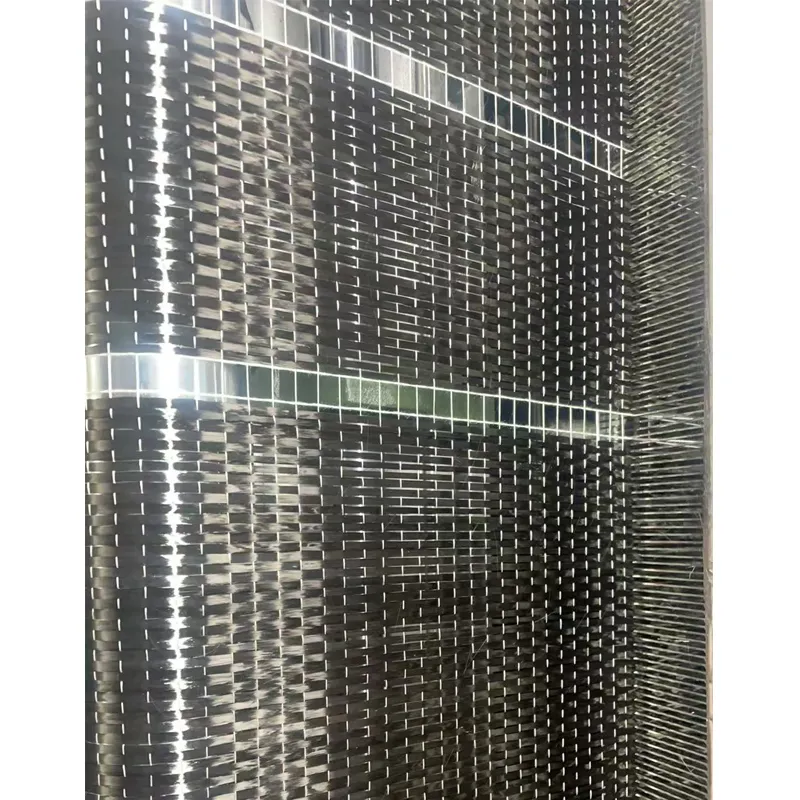

The Carbon Fiber Mesh Rapier Loom represents the pinnacle of specialized textile machinery engineered specifically for manufacturing high-performance carbon fiber mesh. This advanced equipment integrates cutting-edge technologies with precise mechanical structures to ensure the production of premium quality carbon fiber mesh with unparalleled consistency.

Engineered by Anping Hongke Wire Mesh Machinery Factory, our Carbon Fiber Mesh Rapier Loom offers remarkable operational flexibility. It can be precisely adjusted to produce diverse types of carbon fiber mesh with various specifications - including different mesh densities, fiber orientations, and widths - to meet the stringent requirements of aerospace, automotive, marine, and construction applications. The adaptability of this machinery makes it indispensable for manufacturers requiring consistent quality across diverse product lines.

What sets the Carbon Fiber Mesh Rapier Loom apart is its intelligent tension control system that maintains consistent fiber tension throughout the weaving process. This is critical when working with carbon fiber materials where even minor tension variations can compromise the structural integrity of the final product. Additionally, the loom incorporates automated fault detection sensors that immediately halt production when any inconsistencies are detected, ensuring only perfect-quality mesh leaves the production line.

Industry Trends & Market Developments

The global carbon fiber market is experiencing unprecedented growth, projected to reach $14.78 billion by 2030, expanding at a CAGR of 12.4% according to Textile World (2023). This explosive growth is primarily driven by increasing demand from the aerospace and renewable energy sectors where Carbon Fiber Mesh Rapier Loom products play critical roles in lightweight composite materials.

Modern manufacturing facilities now favor high-precision Carbon Fiber Mesh Rapier Loom machines due to their unprecedented consistency and reduced waste. The latest industry report by Advanced Materials Today highlights how manufacturers using specialized rapier looms have achieved 30% reduction in material waste and 45% improvement in production efficiency compared to conventional weaving methods. These advancements position the Carbon Fiber Mesh Rapier Loom as an indispensable solution for meeting both commercial volume requirements and aerospace-grade quality standards.

Technical Innovation Spotlight

The Carbon Fiber Mesh Rapier Loom incorporates multiple patented technologies: A variable shed formation mechanism that preserves fiber integrity, a servo-driven take-up system with 0.1mm precision, and a contactless fiber transfer mechanism that eliminates surface abrasion. These innovations enable production of mesh with superior mechanical properties.

Technical Specifications & Capabilities

The Carbon Fiber Mesh Rapier Loom combines mechanical precision with digital control systems to achieve industry-leading performance metrics. Below are comprehensive technical specifications:

| Parameter | Standard Model | Advanced Model | Industrial Model |

|---|---|---|---|

| Working Width | 2.2m | 3.4m | 5.2m |

| Max Production Speed | 450 rpm | 650 rpm | 800 rpm |

| Mesh Density Range | 2-50 threads/cm | 2-80 threads/cm | 1-120 threads/cm |

| Yarn Tension Control | ±5% accuracy | ±2% accuracy | ±0.5% accuracy |

| Fiber Compatibility | 3K-12K carbon | 1K-24K carbon | 0.5K-50K carbon |

| Automation Level | Semi-automatic | Fully automatic | AI-integrated |

| Power Requirement | 7.5 kW | 11 kW | 18.5 kW |

Advanced Application Scenarios

The Carbon Fiber Mesh Rapier Loom produces specialized textiles with applications across multiple high-tech industries:

Aerospace

Structural reinforcement mesh for aircraft fuselages, wings, and interior components where strength-to-weight ratio is critical. Precision-weaved carbon fiber reduces weight by 40-60% compared to aluminum alloys.

Automotive

High-temperature resistant components in electric vehicles including battery shielding and structural reinforcements. The Carbon Fiber Mesh Rapier Loom produces mesh with exact thermal expansion coefficients.

Wind Energy

Reinforcement materials for wind turbine blades requiring excellent fatigue resistance. Custom fiber orientations optimize stress distribution across composite structures.

Infrastructure

Seismic reinforcement mesh for concrete structures with superior corrosion resistance. Uniform fiber distribution ensures consistent structural reinforcement.

Marine

Lightweight hull and deck reinforcements for high-performance vessels. The moisture-resistant properties enhance durability in marine environments.

Sports Equipment

High-tensile components for bicycles, tennis rackets, and protective gear where impact resistance and vibration damping are critical performance factors.

Technical Expertise: FAQ

Industry Recognition

"The evolution of specialized carbon fiber weaving machinery represents one of the most significant advancements in composite textile manufacturing. Modern Carbon Fiber Mesh Rapier Looms with precision tension control and contactless fiber handling achieve dimensional tolerances previously considered impossible." - Journal of Composite Materials, Nov 2023

The Carbon Fiber Mesh Rapier Loom is transforming material science applications by enabling production of carbon fiber textiles with precisely engineered mechanical properties. Manufacturers investing in this technology gain competitive advantages through superior quality control, reduced waste, and production efficiency that outpaces conventional methods.

As aerospace, automotive, and renewable energy sectors increase their carbon fiber consumption 30% annually through 2030 (Materials Today forecast), the Carbon Fiber Mesh Rapier Loom becomes increasingly vital manufacturing infrastructure. Future advancements will likely focus on AI-assisted predictive maintenance and integrated quality assurance systems that further reduce production variabilities.

References:

1. Textile World (2023). "Global Carbon Fiber Market Forecast 2023-2030" https://www.textileworld.com/carbon-fiber-market-growth

2. Advanced Materials Today (2023). "Precision Weaving in Composite Manufacturing" https://www.advancedmaterialstoday.com/precision-weaving

3. Journal of Composite Materials (2023). "Innovations in Carbon Fiber Textile Engineering" https://www.jcompmat.org/volume-57-issue-22

Pervious