Anping Hongke Wire Mesh Machinery Factory, established in 2008, has emerged as a leading professional wire mesh machine manufacturer with a global export footprint. The factory has successfully delivered advanced machinery to countries including Egypt, Turkey, India, Russia, Saudi Arabia, Romania, and Kazakhstan. Specializing in high - performance high speed loom systems, the company offers innovative solutions for metal mesh machine applications. Our high speed rapier loom models are engineered to meet the demanding needs of modern manufacturing, combining precision, efficiency, and durability. With a focus on technological innovation, Anping Hongke continues to set industry standards in wire mesh weaving technology.

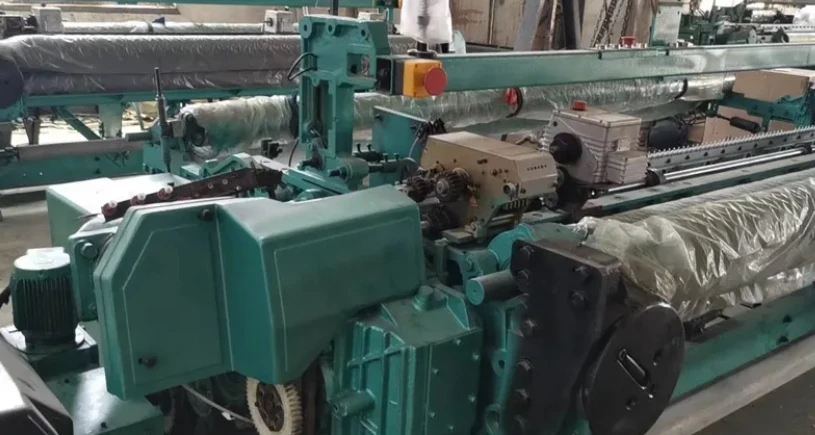

High Speed Loom: Revolutionizing Metal Mesh Production

Anping Hongke’s high speed loom systems redefine productivity in metal mesh manufacturing. These machines are designed to handle diverse materials, including stainless steel, aluminum, and galvanized wire, to produce high - quality meshes for various applications:

- Key Technological Features:

- Cam - Driven Mechanism: Precision - machined cams ensure uniform beating force and stable trajectory, ideal for high - density metal meshes.

- Three - Head Operation: Left, middle, and right heads enable simultaneous weaving, increasing output by 30% compared to traditional looms.

- Weaving Performance:

- Maximum weaving width: Accommodates materials up to 2.5 meters.

- Warp cycles: Capable of 120–180 cycles per minute with folded edges.

Loom Type Comparison:

|

Loom Type |

Weaving Speed |

Material Compatibility |

Application Scenarios |

|

High Speed Loom |

120–180 cycles/min |

Stainless steel, aluminum |

Industrial filtration meshes |

|

Traditional Loom |

40–60 cycles/min |

Basic steel wires |

General - purpose meshes |

Metal Mesh Machine: Versatility in Industrial Applications

The metal mesh machine portfolio from Anping Hongke caters to diverse industrial needs, ranging from architectural screens to heavy - duty filtration systems:

- Application Fields:

- Construction: Reinforcing meshes for concrete structures and facades.

- Filtration: High - precision meshes for chemical and petroleum industries.

- Security: Anti - burglary screens and fencing solutions.

- Machine Adaptability:

- Adjustable weaving density: From coarse to ultra - fine meshes (5–200 TPI).

- Customizable width: Easily adjusted to meet project - specific requirements.

Metal Mesh Applications:

|

Industry |

Mesh Type |

Performance Requirement |

|

Aerospace |

Fine stainless steel |

Corrosion resistance and strength |

|

Automotive |

Aluminum mesh |

Lightweight and impact - resistant |

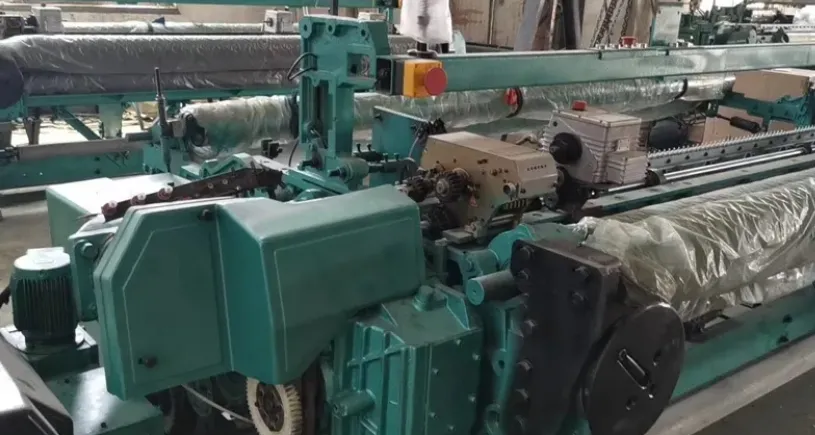

High Speed Rapier Loom: Advanced Weft Insertion Technology

Anping Hongke’s high speed rapier loom incorporates cutting - edge weft insertion technology for precise and efficient weaving:

- Sword Rod Transmission System:

- Rigid or flexible sword rods ensure accurate weft yarn placement through the shed.

- Supports alternating multi - color weft yarns for decorative mesh applications.

- Operational Advantages:

- Wide Adaptability: Handles fabric widths from 2 to 5 meters, suitable for large - scale industrial projects.

- Automated Controls: 3 - stage warp and weft stop systems with automatic training functions.

Weft Insertion Technology Metrics:

|

Feature |

Traditional Loom |

High Speed Rapier Loom |

|

Color Change Capability |

Manual adjustment |

Automatic N - color conversion |

|

Weft Yarn Tension Control |

Basic mechanical |

Precision electronic |

High Speed Rapier Loom Price: Competitive Solutions for Every Budget

Anping Hongke offers high speed rapier loom models at competitive prices, designed to deliver optimal value for different production scales:

- Price Determinants:

- Machine Configuration: Basic models for small - batch production vs. fully automated systems for mass manufacturing.

- Customization Needs: Specialized features such as multi - color conversion or wider weaving widths.

- Price Range Overview:

- Entry - level models: Suitable for small enterprises and start - ups.

- Premium models: Equipped with advanced automation and extended warranties.

Price - Performance Comparison:

|

Model Category |

Price Range |

Key Features |

Return on Investment |

|

Standard |

Competitive |

Basic automation, 120 cycles/min |

12–18 months |

|

Premium |

Higher - end |

Full - scale automation, 180 cycles/min |

8–12 months |

FAQs About High Speed Loom and Metal Mesh Machines

What is the difference between a high speed loom and a traditional loom?

A high speed loom is designed with advanced technology and components that enable it to operate at significantly faster speeds than a traditional loom. It also offers greater flexibility in terms of handling different materials and mesh patterns, and often has more intuitive control systems for easier operation.

Can your metal mesh machines be customized for specific projects?

Yes, Anping Hongke's metal mesh machines can be fully customized. Our team of experts works closely with customers to understand their project requirements and tailors the machines to produce meshes of the desired size, shape, and specification.

How does the high speed rapier loom ensure the quality of the woven mesh?

The high speed rapier loom uses a precise rapier system for weft insertion, which ensures that the weft yarn is accurately placed across the warp threads. This, combined with the loom's stable construction and advanced control systems that monitor and adjust parameters like tension, guarantees a uniform and high - quality weave.

What factors should I consider when comparing high speed rapier loom prices?

When comparing high speed rapier loom prices, consider factors such as the machine's features (like automation level, speed, and weft yarn compatibility), its build quality, the included after - sales service, and any customization options available. It's important to balance price with the overall value and performance the loom offers.

Does Anping Hongke provide training for operating the high speed looms and metal mesh machines?

Yes, we offer comprehensive training programs for all our machines. Our training covers everything from basic operation and parameter adjustment to maintenance and troubleshooting, ensuring that your operators can use the machines safely and efficiently.

Partner with Anping Hongke for Advanced Weaving Solutions

Anping Hongke Wire Mesh Machinery Factory delivers innovative high speed loom and metal mesh machine solutions that drive productivity and quality in modern manufacturing. Our high speed rapier loom models combine advanced technology with reliable performance, offering competitive pricing and global after - sales support. Contact us today to explore customized weaving solutions for your industrial needs—let’s transform your metal mesh production with high - speed innovation.