- Introduction: Why Window Fly Screens are Essential and Their Growing Demand

- The Science Behind Fly Screens: Technical Insights and Key Features

- Manufacturer Comparison: Evaluating Performance, Costs, and Benefits

- Choosing the Right Custom Solution: Materials and Design Considerations

- Step-by-Step Guide: From Measurement to Installation

- Real-World Applications: Case Studies Across Residential and Commercial Settings

- Final Thoughts on How to Make a Window Fly Screen for Lasting Efficiency

(how to make a window fly screen)

Introduction: The Increasing Demand for How to Make a Window Fly Screen

In a world striving for a balance between indoor comfort and environmental safety, the use of window fly screens has evolved from a luxury to an essential household solution. Data from the Global Insect Screen Market Report 2023 indicates that annual worldwide demand for fly screens has surged by over 15% since 2020, primarily driven by urbanization, climate change, and increasing health consciousness regarding airborne pests and insects. More than 68% of newly constructed residential properties in North America and Europe now integrate fly screens as a standard feature, reflecting their rising popularity. Understanding how to make a window fly screen

empowers homeowners and professionals alike to ensure indoor spaces remain protected, ventilated, and pest-free, while adhering to energy-efficiency and sustainability targets.

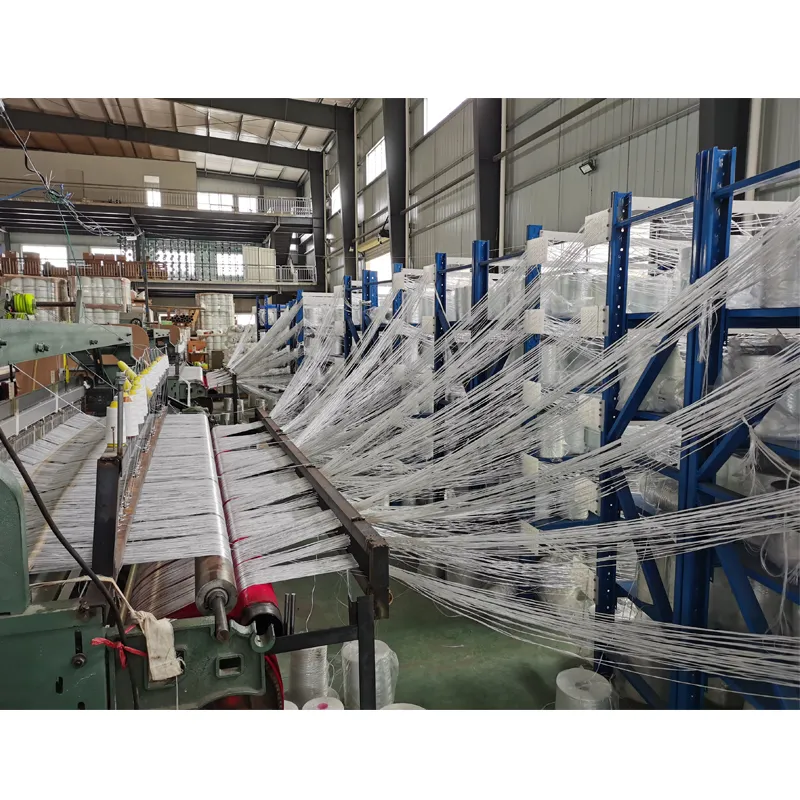

The Science Behind Fly Screens: Technical Insights and Key Features

Window fly screens are engineered with a fine mesh material, with mesh sizes typically ranging between 16x16 and 20x20 per square inch, designed to block pests while allowing optimal airflow and light. Studies show that a tightly woven fiberglass mesh can reduce the entry of mosquitoes and tiny insects by up to 98%, while metal meshes—often made from aluminum or stainless steel—provide superior durability and fire resistance. Ultra-fine polyester screens, popular in Europe, are also treated with UV stabilizers to extend lifespan in harsh climates. The choice of material significantly affects not just cost, but also maintenance schedules and lifespan; for example, a high-grade aluminum fly screen can last 10 to 15 years with minimal upkeep. Advanced features, such as anti-pollen coatings and magnetic seal frames, are gaining traction among homeowners seeking additional health benefits and improved operability.

Manufacturer Comparison: Evaluating Performance, Costs, and Benefits

Selecting the most suitable fly screen manufacturer means weighing factors such as price, durability, customization options, and customer support. The table below offers a comparative analysis of three leading manufacturers based on independent consumer reports and technical documentation:

| Manufacturer | Mesh Material | Durability (Years) | Customization | Average Cost (per sqm) | Customer Rating | Warranty (Years) |

|---|---|---|---|---|---|---|

| ScreenMaster Pro | Aluminum | 12 | High: Colors, Magnetic, Retractable | $32 | 4.8/5 | 10 |

| VistaGuard | Fiberglass | 8 | Medium: Sizes & Basic Colors | $22 | 4.5/5 | 5 |

| PestShield | Polyester (UV Coated) | 9 | High: Shapes, Child-Safe Options | $28 | 4.7/5 | 7 |

As reflected above, the best choice often depends on specific needs such as budget constraints, targeted longevity, or preferences for advanced options like magnetic seals and powder-coated frames. When considering large-scale deployment or retrofitting, manufacturers offering longer warranties and more customization often represent superior long-term value.

Choosing the Right Custom Solution: Materials and Design Considerations

Determining how to make a fly screen for a window that meets unique requirements starts with a clear understanding of local environmental challenges and window configurations. Coastal properties, for instance, benefit from corrosion-resistant stainless steel, while allergy-prone households favor anti-pollen meshes. Frame materials—ranging from economical PVC to robust powder-coated aluminum—also impact both the visual aesthetic and structural integrity of the installation. Customization extends to color matching, integrated handles, pet-resistant screens, and even retractable models that disappear into window frames when not in use. According to a survey by HomePro Network, 39% of customers now seek bespoke solutions over standard sizes, citing improved fit and enhanced appearance as top reasons. Engaging with suppliers to specify correct sizing, mesh density, and mounting method is essential in achieving optimal long-term performance.

Step-by-Step Guide: From Measurement to Installation

Creating an effective fly screen begins with precise measurements. Using a steel tape measure, record the height and width of the window opening, typically adding 10mm to each dimension to ensure full coverage. Choose the desired mesh type and cut it to size, allowing for a 25mm overlap on all sides. Fit the mesh into a pre-constructed frame using spline and a rolling tool, ensuring the mesh is taut but not overly stretched. For mounting, options include adhesive magnetic strips, simple hook-and-loop tape for rental applications, or screw-in brackets for permanent installations. Recent developments in fly screen systems include modular snap-fit corners, which reduce installation time by up to 40%, and child-safe locking mechanisms. Final quality checks include inspecting for gaps and ensuring a snug seal to prevent insect ingress around the frame. Routine cleaning—preferably twice a year using a mild detergent and soft brush—will prolong mesh clarity and frame longevity.

Real-World Applications: Case Studies Across Residential and Commercial Settings

The deployment of fly screens is no longer confined to household windows. In 2022, a UK-based hospital reduced vector-borne infection rates by 27% across two seasons after installing stainless steel fly screens throughout patient wards. Similarly, a chain of café franchises in Australia has achieved a reported 95% drop in reported customer complaints about insects, attributed to an upgrade to custom-fit magnetic fly screens on all storefront windows and doors. In high-end residential settings, architects are specifying retractable fly screens with powder-coated designer frames, which are visually unobtrusive and complement energy-efficient glazing. Office complexes report not only a sharp decline in insect-related disruptions but also a modest 4-7% reduction in HVAC loads during summer, thanks to improved natural ventilation. These practical examples illustrate the adaptability and long-term return on investment of high-quality fly screens across diverse settings.

Final Thoughts on How to Make a Window Fly Screen for Lasting Efficiency

Mastering the art and process of how to make a window fly screen is as much about technical accuracy as it is about fitting individual needs and architectural styles. As consumer priorities shift towards healthier living environments and sustainable home improvements, data-led decision making—combined with carefully selected materials and professional customization—remains key. When appropriately installed and maintained, modern fly screens provide years of unobtrusive service, delivering indoor comfort and protection while enhancing property value. By prioritizing a thorough understanding of technical options, reputable manufacturers, and real-world application, homeowners and professionals alike secure long-term efficiency and peace of mind.

(how to make a window fly screen)

FAQS on how to make a window fly screen

Q: How to make a window fly screen at home?

A: To make a window fly screen at home, measure your window, buy fly screen mesh, and an appropriate frame. Cut the mesh and frame to size, then assemble and attach to your window. Secure with adhesive strips or screws for a snug fit.Q: What materials do I need to make a fly screen for a window?

A: You'll need fly screen mesh, a frame kit, scissors or a utility knife, and measuring tape. Optional materials include adhesive tape, Velcro, or screen spline. These are all available at most hardware stores.Q: Can I make removable fly screens for windows?

A: Yes, you can make removable fly screens by attaching the mesh to the frame and using Velcro or magnetic strips. This allows easy installation and removal for cleaning. It's a popular DIY solution for renters.Q: How do I cut the mesh for making fly screens?

A: Use sharp scissors or a utility knife to cut the fly screen mesh slightly larger than your window opening. Trim any excess after fitting it into the frame. Be careful to avoid fraying the mesh edges.Q: Are homemade window fly screens as effective as store-bought ones?

A: Homemade window fly screens can be just as effective as store-bought versions if made correctly. The key is ensuring a tight fit with no gaps around the frame. Using quality mesh also helps provide effective insect protection.

Pervious