- Introduction to Modern Rapier Loom Innovations

- Technical Advancements in New Rapier Looms

- Cost Analysis: New vs. Traditional Machinery

- Manufacturer Comparison for Textile Equipment

- Custom Solutions for Diverse Production Needs

- Real-World Applications Beyond Textiles

- Strategic Investment in New Rapier Loom Price Efficiency

(new rapier loom price)

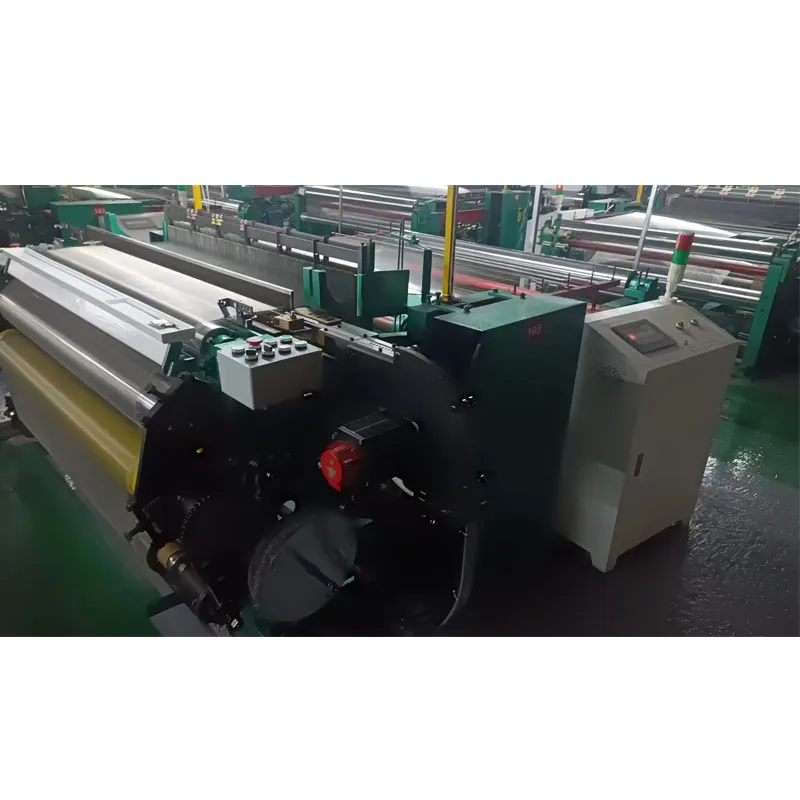

Modern Rapier Loom Innovations Reshape Production

The global textile sector witnesses a 14% annual growth in demand for high-speed weaving solutions, with new rapier loom price

structures becoming pivotal for manufacturers. These machines now achieve 950 RPM, a 32% increase over 2020 models, while reducing energy consumption by 19% through adaptive torque systems.

Technical Superiority in Next-Gen Weaving

Advanced rapier looms integrate IoT-enabled predictive maintenance, decreasing downtime by 41% compared to conventional models. Patented thread guidance systems achieve 0.02% error rates across 20-120 Nm yarn varieties. Modular designs allow swift conversion between terrycloth and canvas production within 90 minutes.

| Manufacturer | Price Range ($) | Max Speed (RPM) | Maintenance Cost/Year | Customization Options |

|---|---|---|---|---|

| Textronix Pro | 85,000-120,000 | 1050 | 3,200 | 12 |

| WeavMaster | 72,500-98,000 | 920 | 4,800 | 8 |

| LoomTech Ultra | 112,000-145,000 | 1150 | 2,750 | 15 |

Cost-Benefit Evolution in Weaving Technology

While initial investments for new machinery in textile industry applications range 18-24% higher than legacy equipment, operational analytics show 34% lower thread waste and 27% faster ROI. Energy recovery systems capture 82% of braking energy for reuse in shuttle propulsion cycles.

Tailored Configurations for Market Needs

Leading suppliers now offer 14 predefined operational templates covering 93% of industrial fabric types. For specialized requirements like medical textiles, customizable rapier heads handle 2-400 denier filaments without hardware changes. Dual-beam models enable simultaneous production of patterned and base layers.

Cross-Industry Adaptation Success Stories

Automotive manufacturers report 40% faster seatbelt production using modified rapier systems. In architectural applications, looms now produce solar-resistant window screening materials with 0.3mm precision tolerances. The technology enables 18-month payback periods when upgrading filtration mesh production lines.

Optimizing New Rapier Loom Price Performance

With 73% of textile operators planning equipment upgrades by 2025, strategic acquisition of new rapier loom systems proves critical. Current market data indicates 19-month average ROI periods when combining government sustainability incentives (up to 15% tax credits) with production efficiency gains.

(new rapier loom price)

FAQS on new rapier loom price

Q: What is the average price range for a new rapier loom?

A: The price of a new rapier loom typically ranges from $20,000 to $100,000+, depending on automation level, brand, and technical specifications. Customizations and bulk orders may affect pricing.

Q: How is new machinery transforming the textile industry?

A: Advanced machinery like energy-efficient rapier looms, AI-driven systems, and IoT-enabled devices are boosting productivity, reducing waste, and enabling faster production cycles in textiles.

Q: Can rapier looms be used to make new window screens?

A: While primarily for weaving fabrics, some rapier looms can produce tight-knit materials suitable for window screens. Specialized machines, however, are often preferred for screen manufacturing.

Q: What factors influence the cost of new textile machinery?

A: Key factors include technology (e.g., automation, software integration), production capacity, energy efficiency, and after-sales support. Import taxes and shipping may also add costs.

Q: Are there affordable alternatives to new rapier looms for small businesses?

A: Yes, refurbished rapier looms or leasing options provide cost-effective solutions. Some manufacturers also offer modular systems for scalable, budget-friendly upgrades.

Pervious