PE PPE PET Insect Window Screen Machine: Precision Engineering for Modern Pest Control

Discover how Anping Hongke Wire Mesh Machinery Factory's advanced machinery revolutionizes the production of durable insect-proof screens, combining cutting-edge technology with industry-leading efficiency.

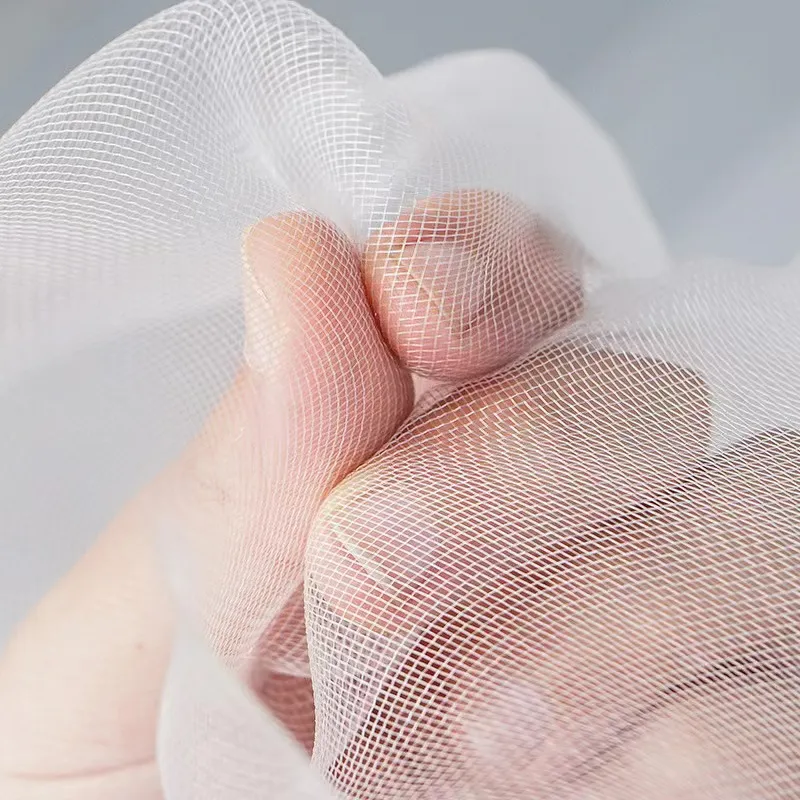

Introduction to the PE PPE PET Insect Window Screen Machine

The PE PPE PET Insect Window Screen Machine represents a significant advancement in the manufacturing of insect-proof screens, offering a comprehensive solution for agricultural, industrial, and residential applications. This machine integrates multiple specialized components, including the wire drawing machine, wire winding machine, warping machine, and weaving machine, to produce high-quality mesh screens that meet stringent durability and performance standards. Developed by Anping Hongke Wire Mesh Machinery Factory, a leading manufacturer in China's wire mesh machinery industry, this system ensures precision, efficiency, and scalability in screen production.

Core Functions and Technical Specifications

The PE PPE PET Insect Window Screen Machine is a multi-component system designed to streamline the production of insect-proof screens. Each component plays a critical role in the manufacturing process, ensuring the final product meets exacting standards for strength, flexibility, and durability.

Wire Drawing Machine

The wire drawing machine is the first stage in the production process. After heating and melting, the machine uses a mold to extrude plastic wire blanks. These blanks are then passed through a stretching device to achieve the desired fineness, enhancing the wire's strength, bending resistance, and roundness. Key specifications include:

- Dimensions: 25 meters (length) × 2 meters (height) × 1.5 meters (width)

- Main motor: 11 kW variable frequency

- Stretching mechanism: 1.5 kW variable frequency for seven rods (273 × 12) and 4 kW variable frequency for seven rods (273 × 10)

Wire Winding Machine

The wire winding machine features dual-axis winding power and 1.5 kW speed regulation. It is equipped with two extruders with 65-type screws and electromagnetic heating. Additional features include:

- Hot water tank: 24 kW

- Electromagnetic heating: 10 kW

- Cold water supply

- Width: 500 × 1000 mm

- Large axis wire splitting machine: 100 units of 0.37 kW torque motors

- Small axis wire splitting machine: 0.75 kW

Warping Machine

The warping machine ensures even distribution of PE fibers onto the warp axis, maintaining tension and alignment for optimal weaving. Available models include 280, 330, 430, and 540 types, each tailored for specific production needs.

Weaving Machine

The weaving machine combines warp and weft wires to create insect-proof nets. The Hongke grid weaving machine enhances efficiency through technological upgrades, producing flat nets with mesh holes ranging from 50-6 mesh to 60 silk. Key specifications include:

- Model configurations: 230, 260, 280, 330, 430, 540 types

- Dimensions: 6 meters (length) × 1.8 meters (width) × 1.8 meters (height)

- Power: 1.5 kW

- Weight: 2 tons

- Beating frequency: 130-150 times per minute

Product Specifications Table

| Component | Key Specifications |

|---|---|

| Wire Drawing Machine | 25m x 2m x 1.5m, 11 kW motor, 1.5 kW/4 kW stretching mechanism |

| Wire Winding Machine | Dual-axis winding, 24 kW hot water tank, 10 kW electromagnetic heating |

| Warping Machine | 280, 330, 430, 540 models |

| Weaving Machine | 6m x 1.8m x 1.8m, 1.5 kW power, 130-150 bpm beating frequency |

Applications and Industry Impact

The PE PPE PET Insect Window Screen Machine is designed for a wide range of applications, including:

- Agricultural insect prevention: Protecting crops from pests while maintaining optimal airflow.

- Building safety nets: Enhancing structural integrity and security in residential and commercial buildings.

- Aquaculture nets: Providing durable, corrosion-resistant solutions for fish farming and aquatic environments.

- Grape drying: Facilitating efficient and hygienic drying processes in agricultural settings.

According to the National Institute of Standards and Technology (NIST), the integration of precision-engineered machinery in manufacturing processes significantly improves product consistency and performance. The PE PPE PET system exemplifies this principle, offering a reliable solution for industries requiring high-quality mesh screens.

Company Background: Anping Hongke Wire Mesh Machinery Factory

Based in Anping Hongke Wire Mesh Machinery Factory, a leading manufacturer in China's wire mesh machinery sector, this company has established itself as a trusted provider of innovative solutions for the agricultural and industrial sectors. With a focus on research and development, Anping Hongke combines traditional craftsmanship with modern technology to deliver machinery that meets global standards.

The company's commitment to quality is reflected in its adherence to international production standards. As highlighted by NIST, rigorous testing and validation are essential for ensuring the reliability of industrial equipment. Anping Hongke's machines undergo comprehensive quality control processes to guarantee durability, efficiency, and compliance with industry regulations.

Advantages of the PE PPE PET Insect Window Screen Machine

1. Enhanced Efficiency: The integrated system reduces production time and labor costs by automating multiple stages of the manufacturing process.

2. Customizable Solutions: Available in various models and configurations, the machine caters to diverse production requirements, from small-scale operations to large industrial facilities.

3. Durability and Flexibility: The use of high-quality materials and advanced engineering ensures the machine's longevity and adaptability to different mesh specifications.

4. Environmental Sustainability: The system's energy-efficient design and minimal waste production align with global sustainability goals.

Conclusion: A Comprehensive Solution for Insect-Proof Screen Production

The PE PPE PET Insect Window Screen Machine by Anping Hongke Wire Mesh Machinery Factory is a testament to the power of innovation in industrial manufacturing. By combining advanced technology, precise engineering, and a commitment to quality, this system offers an efficient and reliable solution for producing durable insect-proof screens. Whether for agricultural, industrial, or residential use, the machine meets the evolving needs of modern industries while adhering to global standards of performance and sustainability.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov/

Anping Hongke Wire Mesh Machinery Factory. (n.d.). Official Website.

Pervious