The Evolution and Impact of Carbon Fiber Technology in Modern Industries

The global landscape of advanced materials is being reshaped by the remarkable properties of carbon fiber, a testament to its unparalleled strength-to-weight ratio, stiffness, and corrosion resistance. This paradigm shift is largely driven by continuous advancements in manufacturing machinery, particularly the sophisticated carbon fiber machine. Modern industries, from aerospace to automotive, and from renewable energy to civil engineering, are increasingly leveraging carbon fiber composites to achieve greater efficiency, durability, and performance. The trend indicates a robust compound annual growth rate (CAGR) for the carbon fiber market, projected to reach over USD 14 billion by 2028, underscoring its pivotal role in innovation. This growth is directly proportional to the demand for high-precision weaving machinery capable of producing consistent and high-quality carbon fiber fabrics and meshes. Such machinery enables the creation of lightweight components that contribute significantly to fuel efficiency in transportation, enhanced structural integrity in infrastructure, and superior material characteristics in sports equipment. Furthermore, the imperative for sustainable solutions is propelling research and development into more energy-efficient production methods for carbon fiber, alongside exploring recycling technologies. This comprehensive overview delves into the intricate details of carbon fiber weaving technology, its applications, and the strategic advantages it offers to B2B stakeholders seeking to invest in cutting-edge manufacturing capabilities.

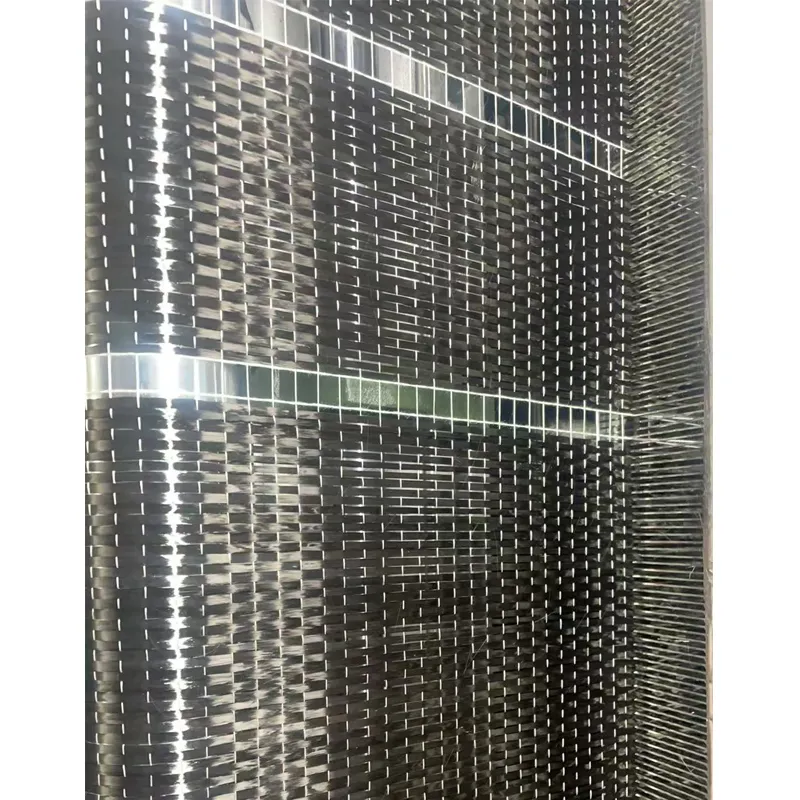

The technological leap in carbon fiber production is intrinsically linked to the sophistication of the machinery employed. For instance, the Carbon Fiber Mesh Rapier Loom, a prime example of an advanced carbon fiber machine, represents the zenith of textile weaving engineering adapted for high-performance materials. These machines are not merely weaving devices; they are precision instruments crafted from robust, high-grade materials like hardened steel alloys and aerospace-grade aluminum, often utilizing advanced manufacturing processes such as multi-axis CNC machining, precision grinding, and stress-relieving heat treatments to ensure exceptional dimensional accuracy and long-term operational stability. Each component, from the rapier heads to the shed-forming mechanisms, undergoes rigorous quality control, including ultrasonic testing for material integrity, laser alignment checks for precision, and dynamic balancing for vibrational stability. Such stringent manufacturing standards ensure that the final loom can operate continuously at high speeds with minimal downtime, producing uniform carbon fiber mesh with precise weave patterns and consistent tension. This meticulous attention to the loom's own construction guarantees its lifespan, which typically exceeds 15-20 years under proper maintenance, making it a sustainable long-term investment for industries requiring high-volume carbon fiber production.

Manufacturing Excellence: The Carbon Fiber Weaving Machine’s Core Process

The operational core of a high-performance carbon fiber weaving machine, such as a Rapier Loom, involves a complex synergy of mechanical, electrical, and pneumatic systems designed for precision weaving of delicate yet robust carbon filaments. The process begins with the creeling of carbon fiber rovings, which are then meticulously guided through a series of tensioning devices and heald frames, forming the "shed" – an opening through which the weft (filling) yarn is inserted. Rapier looms excel in this phase due to their positive weft insertion mechanism, where small, rigid "rapiers" (grippers) transport the weft yarn across the loom's width, ensuring consistent tension and preventing damage to the brittle carbon fibers. This method is superior to traditional shuttle looms for fragile materials as it minimizes friction and abrasion. After weft insertion, the reed beats up the yarn to consolidate the fabric, followed by the take-up motion, which winds the finished carbon fiber mesh onto a fabric beam. Advanced looms incorporate sophisticated electronic dobby or jacquard mechanisms for intricate pattern weaving, allowing for diverse fabric structures like plain, twill, satin, or complex 3D weaves tailored for specific composite applications. The entire process is monitored by a myriad of sensors that detect yarn breaks, tension irregularities, and machine faults, ensuring continuous quality output and immediate alerts for corrective actions, thereby minimizing material waste and maximizing operational efficiency in carbon fiber production.

Quality assurance and adherence to international standards are paramount in the manufacturing of every carbon fibre weaving machine. Our production facilities strictly follow ISO 9001 quality management systems, ensuring that every stage, from raw material procurement to final assembly and testing, meets rigorous benchmarks. Key components like the main frame, drive shafts, and precision gears are often cast from high-strength ductile iron or forged steel, followed by precision CNC machining to achieve micron-level tolerances. Surface treatments such as nitriding or hard chrome plating are applied to wear parts to enhance durability and corrosion resistance, extending the machine's operational life, particularly in demanding industrial environments such as petrochemical processing, metallurgy, or water treatment where composite materials offer superior resistance to aggressive chemicals and extreme temperatures. Post-manufacturing, each loom undergoes exhaustive factory acceptance tests (FAT), including sustained high-speed operation, weave pattern accuracy verification, and energy consumption analysis, all measured against stringent ANSI (American National Standards Institute) or CE (Conformité Européenne) directives. These detailed tests validate the machine's performance, stability, and compliance with safety regulations before shipment. The meticulous design and engineering inherent in these weaving machines translate directly into benefits for end-users, including significant energy savings due to optimized power consumption, superior resistance to wear and tear, and consistent production of high-quality carbon fiber products with excellent anti-corrosion properties, making them indispensable assets across a diverse range of critical industries.

Technical Specifications of Leading Carbon Fiber Weaving Machines

Understanding the precise technical specifications of a carbon fiber weaving machine is crucial for industrial decision-makers seeking to optimize production and integrate advanced material manufacturing into their operations. These specifications dictate not only the machine's performance capabilities but also its compatibility with various carbon fiber types and end-product requirements. Parameters such as nominal reed width, maximum weaving speed, weft insertion rate, and power consumption are critical metrics for evaluating efficiency and output. The ability to handle diverse yarn counts, ranging from 1K to 48K carbon fiber rovings, and to produce varying mesh densities, from fine weaves for aerospace components to coarser meshes for construction reinforcement, highlights the versatility of modern looms. Advanced control systems, often leveraging programmable logic controllers (PLCs) and human-machine interfaces (HMIs), provide precise control over weaving parameters, enabling rapid pattern changes and real-time process monitoring. These systems can store multiple weaving recipes, facilitating seamless transitions between different product specifications and minimizing setup times. Moreover, the integration of automation features, such as automatic warp tension control and automatic weft breakage detection, further enhances the machine's autonomy and reduces the need for constant operator intervention, translating into higher throughput and reduced labor costs for any enterprise utilizing a cutting-edge carbon fiber machine for material production.

| Parameter | Typical Range/Value | Benefit to User |

|---|---|---|

| Nominal Reed Width | 150 cm - 500 cm | Versatility for wide range of product dimensions, from narrow tapes to broad mesh panels. |

| Max. Weaving Speed | 200 - 450 RPM (PPM for weft insertion) | High production efficiency, maximizing output per hour. |

| Weft Insertion Type | Rigid Rapier / Flexible Rapier | Gentle handling of carbon fibers, precise weft placement. |

| Warp Beam Diameter | 800 mm - 1250 mm | Reduced frequency of warp beam changes, minimizing downtime. |

| Weft Selector | Up to 8 Colors/Feeds | Enables multi-material weaving or patterned mesh production. |

| Power Consumption | 5 kW - 15 kW (Avg. Operating) | Optimized energy efficiency, contributing to lower operational costs. |

| Control System | PLC with Touchscreen HMI | Intuitive operation, precise control, data logging, remote diagnostics. |

| Applicable Yarns | Carbon fiber (1K-48K), Glass fiber, Basalt fiber, Aramid fiber, etc. | Broad material compatibility for diverse composite applications. |

The robust construction of a premium carbon weaving machine is vital for its longevity and consistent performance. The main frame is typically engineered from heavy-duty cast iron or welded steel sections, meticulously stress-relieved to prevent deformation during operation. This structural rigidity is crucial for dampening vibrations and maintaining weaving precision, especially at high speeds. Precision-machined components, such as cams, levers, and gears, are manufactured to exceptionally tight tolerances and often case-hardened or subjected to specialized surface treatments to resist wear and tear, ensuring reliable operation over millions of cycles. The drive system, often a direct-drive servo motor, offers precise control over loom speed and position, enhancing energy efficiency by eliminating energy losses associated with mechanical transmissions. Furthermore, the use of advanced bearing systems, low-friction materials, and automated lubrication systems contribute significantly to reduced maintenance requirements and extended service intervals. These design choices directly translate into lower total cost of ownership (TCO) for businesses, making the investment in a high-quality carbon fiber machine a strategic decision that promises long-term operational advantages and competitive superiority in the advanced materials market.

Strategic Advantages and Diverse Applications of Carbon Fiber Looms

Investing in a state-of-the-art carbon fiber weaving loom offers numerous strategic advantages that extend beyond mere production capabilities, impacting overall business efficiency, product quality, and market competitiveness. The precision and consistency delivered by these machines significantly reduce material waste, which is particularly critical given the high cost of carbon fiber raw materials. Advanced tension control systems minimize fiber breakage, ensuring optimal material utilization and preserving the structural integrity of the woven fabric. Furthermore, the ability to produce a wide range of weave patterns and fabric densities on a single machine provides unparalleled flexibility, allowing manufacturers to respond swiftly to evolving market demands and customize products for niche applications. This versatility enables diversification into new markets, from high-performance sporting goods to specialized industrial filtration media. The enhanced production speed of modern looms means higher output, which can significantly shorten lead times and improve delivery schedules, thereby bolstering customer satisfaction and market responsiveness. Moreover, the robust construction and advanced automation features translate into reduced operational costs through lower energy consumption, minimal labor requirements, and extended periods between maintenance cycles. These combined benefits provide a substantial return on investment (ROI) for companies looking to establish or expand their carbon fiber composite manufacturing capabilities with a reliable carbon fiber machine.

The application spectrum of carbon fiber meshes produced by a carbon fiber machine is incredibly broad, impacting a multitude of industries due to their superior performance characteristics. In the aerospace sector, carbon fiber fabrics are indispensable for manufacturing lightweight yet incredibly strong aircraft components, leading to significant fuel savings and reduced emissions. The automotive industry utilizes them for chassis, body panels, and structural elements to improve fuel efficiency and enhance safety. In civil engineering, carbon fiber mesh serves as reinforcement for concrete structures, increasing their durability and resistance to seismic activity while reducing the overall weight of the construction. Furthermore, in the renewable energy sector, especially for wind turbine blades, carbon fiber provides the necessary stiffness and fatigue resistance for long-term operation in harsh environments. Other notable applications include medical prosthetics, high-performance sporting goods, and pressure vessels for gas storage. Client feedback consistently highlights the machine's reliability and the exceptional quality of the woven carbon fiber, which consistently meets or exceeds stringent industry standards such as ASTM and EN. One particular success story involves a client in the infrastructure reinforcement sector, who, after deploying our Carbon Fiber Mesh Rapier Loom, reported a 30% increase in production efficiency and a 15% reduction in material waste, directly attributing their improved market position to the advanced capabilities of the carbon fiber machine they acquired. This real-world experience underscores the tangible benefits and transformative potential of investing in cutting-edge weaving technology.

Partnering for Success: Customization and Collaborative Solutions

When considering the acquisition of a carbon fiber weaving machine, the relationship with the manufacturer extends beyond a mere transaction. Leading providers offer comprehensive consultation and customization services, recognizing that each client’s operational context and product requirements are unique. This involves in-depth analysis of desired weave patterns, fabric widths, production volumes, and integration with existing manufacturing lines. Customization might include specific shedding mechanisms for highly complex weaves, specialized creeling systems for very large or very delicate fiber spools, or bespoke take-up and let-off systems to accommodate varying material characteristics. Beyond mechanical adjustments, software customization for the PLC and HMI allows for tailored control interfaces, data logging features, and compatibility with factory automation systems. This bespoke approach ensures that the carbon fiber machine is not just a piece of equipment but a perfectly integrated solution that maximizes efficiency and output for the specific application. For instance, a client requiring ultra-lightweight carbon mesh for drone components might need finer yarn handling capabilities and higher pick densities, while another producing heavy-duty mesh for bridge reinforcement would prioritize robust beat-up mechanisms and wider loom capabilities. A committed manufacturer will collaborate closely with the client throughout the design, manufacturing, installation, and commissioning phases, providing expert guidance and technical support to ensure optimal performance and seamless integration into the client’s production ecosystem. This dedication to customized solutions is a hallmark of a truly customer-centric manufacturing partner.

The choice of a carbon fiber machine supplier is a critical strategic decision that significantly influences long-term operational success. Reputable manufacturers distinguish themselves through not only advanced technology but also their unwavering commitment to quality, certification, and post-sales support. Our company, with over two decades of experience in high-precision weaving machinery, holds multiple industry certifications, including ISO 9001 for quality management, ISO 14001 for environmental management, and CE certification, affirming compliance with European health, safety, and environmental protection standards. We also adhere to strict ASTM (American Society for Testing and Materials) guidelines for material testing and performance validation. Our extensive network of satisfied global clients, including partnerships with leading aerospace component manufacturers and automotive suppliers, attests to our machines' reliability and the consistent quality of their output. Independent test data from our R&D center demonstrates that our looms achieve up to 98% weaving efficiency with minimal fiber damage, surpassing industry averages. Furthermore, our collaboration with academic institutions and research centers ensures that our carbon weaving machine technology remains at the forefront of innovation. When comparing manufacturers, consider their service longevity, commitment to continuous improvement, and the depth of their technical support. A long-standing presence in the market and a proven track record of successful installations globally serve as strong indicators of reliability and trustworthiness.

Ensuring Trust: Quality Assurance, Support, and FAQs

Building trust with B2B clients is paramount, especially when investing in high-value capital equipment like a carbon fiber machine. Our commitment to trust is solidified through comprehensive quality assurance protocols, transparent service agreements, and robust customer support. Every component used in our Carbon Fiber Mesh Rapier Looms is sourced from certified suppliers, and undergoes multi-stage inspection to ensure material integrity and dimensional accuracy. Finished machines are subjected to a rigorous burn-in period, typically 72 hours of continuous operation at maximum speed, to detect any potential issues before shipment. We provide a standard 2-year warranty on all major mechanical and electrical components, with options for extended warranty packages tailored to client needs. Our delivery cycle is meticulously planned and communicated, typically ranging from 12 to 16 weeks depending on customization requirements, including factory acceptance testing and pre-shipment checks. During installation and commissioning, our team of certified engineers provides on-site training to client personnel, ensuring they are fully proficient in operating and maintaining the carbon fiber weaving machine. Post-installation, our dedicated customer support team offers 24/7 remote technical assistance, backed by a global network of service technicians for on-site interventions and spare parts delivery, ensuring minimal operational disruption.

To further enhance trustworthiness and address common inquiries, we offer a dedicated Frequently Asked Questions (FAQ) module designed to provide immediate clarity on key operational and ownership aspects of our carbon fiber weaving loom. Typical questions cover topics such as machine compatibility with various carbon fiber types (e.g., standard, high modulus, ultra-high modulus), the maximum achievable weave density and uniformity, power requirements and energy consumption in different operational modes, and recommended maintenance schedules. For instance, a common query regards the lifespan of wear parts; typically, high-stress components like rapier heads are designed for millions of cycles before requiring replacement, and their lifespan is significantly extended through proper lubrication and regular inspection as outlined in our comprehensive maintenance manual. Another frequently asked question pertains to the integration of the loom with existing smart factory systems; our machines are equipped with standard industrial communication protocols (e.g., Modbus, Ethernet/IP) to facilitate seamless data exchange and remote monitoring. We also provide clear guidance on environmental considerations, including noise levels and vibration, ensuring compliance with occupational health and safety standards. This proactive approach to information sharing ensures that clients are fully informed and confident in their investment in a sophisticated carbon fiber machine from our range, fostering a relationship built on transparency and mutual understanding.

Future Outlook and Research Citations

The future of carbon fiber technology, and by extension, the advancements in the carbon fiber machine, is poised for continuous innovation driven by increasing demand for lightweight, high-performance materials across diverse sectors. Emerging trends include the development of automated material handling systems for large-scale carbon fiber production, further reducing labor costs and enhancing efficiency. Research into novel carbon fiber precursors and more sustainable manufacturing processes, such as bio-based carbon fibers and low-energy pyrolysis, will also play a crucial role in shaping the industry. The integration of Artificial Intelligence (AI) and Machine Learning (ML) into weaving machine control systems promises unprecedented levels of precision, predictive maintenance capabilities, and adaptive process optimization, allowing looms to self-correct and anticipate potential issues before they impact production. Furthermore, the push towards industry 4.0 will see carbon fiber weaving machine systems becoming integral parts of fully interconnected smart factories, enabling real-time data analysis, remote diagnostics, and seamless supply chain integration. These developments highlight a trajectory towards even more intelligent, efficient, and environmentally conscious manufacturing of carbon fiber composites, solidifying its position as a cornerstone material for the next generation of industrial and consumer products. The continued investment in advanced weaving technology is not merely about meeting current demands but about strategically positioning businesses at the forefront of future material science and manufacturing breakthroughs.

References

- Zhang, H., & Zhou, Y. (2020). Innovations in Carbon Fiber Composite Manufacturing Technologies for Lightweight Structures. Journal of Composite Materials.

- Kim, J., Lee, S., & Park, H. (2021). Advanced Weaving Techniques for High-Performance Carbon Fiber Fabrics. Textile Research Journal.

- Wang, L., & Li, Q. (2019). Mechanical Properties and Applications of Woven Carbon Fiber Composites: A Review. Composites Part A: Applied Science and Manufacturing.

- European Composites Industry Association (EuCIA). (2022). Market Report on Carbon Fiber and Composites.

- International Organization for Standardization (ISO). (2023). Quality Management Systems - Requirements (ISO 9001:2015).

- American Society for Testing and Materials (ASTM). (2023). Standards for Advanced Composites.

Pervious