In the intricate world of industrial manufacturing, the demand for highly specialized materials and components is ever-growing. Among these, stainless steel wire mesh stands out for its exceptional properties, including corrosion resistance, high strength, and aesthetic appeal. The production of such precise and durable mesh relies entirely on advanced machinery, specifically, a sophisticated a machine for weaving. This comprehensive guide delves into the nuances of these critical machines, focusing on the Stainless Steel Wire Mesh Weaving Machine, exploring its technological prowess, application versatility, and the factors that define its industry leadership.

Industry Trends and Market Dynamics in Wire Mesh Manufacturing

The global wire mesh market is experiencing significant growth, driven by expansion in infrastructure development, industrial filtration needs, and increasing applications in architectural and decorative fields. According to recent market analyses, the global industrial wire mesh market is projected to reach over USD 10 billion by 2027, growing at a CAGR of approximately 5-6%. This surge directly fuels the demand for high-performance a machine for weaving solutions, particularly those capable of handling specialized materials like stainless steel.

Key trends shaping the industry include:

- Automation and IoT Integration: Manufacturers are increasingly adopting automated systems and IoT for real-time monitoring, predictive maintenance, and optimized production, enhancing the efficiency of a weaving machine.

- Material Innovation: Demand for advanced alloys and composites necessitates weaving machines capable of handling diverse material properties, from fine wires to high-tensile strength materials.

- Sustainability: Energy efficiency and reduced waste are paramount, pushing for greener manufacturing processes and more sustainable power loom warping machine designs.

- Precision and Customization: Industries require increasingly precise mesh specifications and custom patterns, driving innovation in weaving machine control systems and versatility.

Understanding the Core Technology: What Defines a Machine for Weaving?

At its heart, a machine for weaving is an intricate piece of engineering designed to interlace warp (longitudinal) and weft (transverse) wires to create a mesh fabric. While the fundamental principle remains the same, modern machines, especially those built for stainless steel, incorporate advanced mechanics, electronics, and control systems to achieve unparalleled precision, speed, and reliability. This section provides a general overview of parameters typical for high-performance weaving machines.

General Parameters of a Weaving Machine

| Parameter | Typical Range for High-Performance Weaving Machine | Unit | Significance |

|---|---|---|---|

| Max Weaving Width | 1200 - 3500 | mm | Determines the width of the final mesh panel, impacting production scale. |

| Wire Diameter Range | 0.02 - 1.2 | mm | Indicates the fineness/coarseness of wires it can process, crucial for mesh type. |

| Mesh Count Range (Weft) | 2 - 600 | mesh/inch | Number of openings per linear inch, defining mesh density and filtration capability. |

| Weaving Speed | 40 - 120 | PPM (Picks Per Minute) | Rate at which weft wires are inserted, directly affecting productivity. |

| Motor Power | 3.0 - 7.5 | kW | Indicates the power consumption and operational capability. |

| Overall Dimensions (L x W x H) | 4000x2500x2000 to 6000x3500x2500 | mm | Space requirement for installation. |

| Machine Weight | 5000 - 15000 | kg | Reflects robustness and stability during high-speed operation. |

| Control System | PLC with HMI | - | Enables precise control, automation, and user interface. |

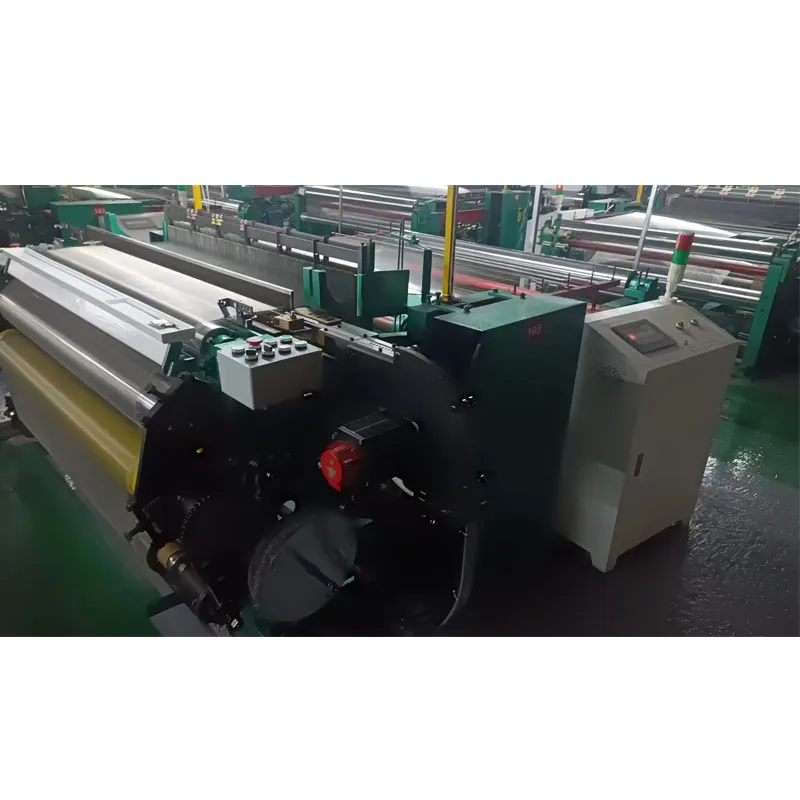

Fig 1: A modern a machine for weaving, showcasing its complex structure and operational capabilities.

Deep Dive into Manufacturing: The Stainless Steel Wire Mesh Weaving Machine

The Stainless Steel Wire Mesh Weaving Machine, specifically designed for processing various grades of stainless steel, represents the pinnacle of weaving technology. This specialized a machine for weaving is engineered to overcome the challenges associated with stainless steel, such as its hardness and spring-back properties, ensuring the production of high-quality, durable mesh.

Product Information: Stainless Steel Wire Mesh Weaving Machine

- Product Name: Stainless Steel Wire Mesh Weaving Machine

- Product URL: https://www.aphkmachinery.com/stainless-steel-wire-mesh-weaving-machine.html

Crafting Precision: The Manufacturing Process Flow of a Machine for Weaving Stainless Steel Mesh

The creation of stainless steel wire mesh involves a highly automated and precise sequence of operations. Understanding this process highlights the engineering excellence embedded in every a machine for weaving.

-

Warp Beam Preparation & Creeling:

- Description: Stainless steel warp wires (longitudinal wires) are individually wound onto a large warp beam or multiple smaller section beams. The creeling process involves feeding these wires from the bobbins through tensioning devices and guiding them onto the beam, ensuring uniform tension across all wires.

- Key Nodes: Tension Control Systems (e.g., electronic let-off mechanisms), Warp Beam Winder.

- Significance: Consistent warp tension is crucial for uniform mesh openings and preventing wire breakage, especially with the high tensile strength of stainless steel.

-

Shedding Mechanism:

- Description: The warp wires pass through heald frames (also known as harnesses), which are controlled by a shedding mechanism (e.g., a crank shedding, cam shedding, or electronic dobby/jacquard system). This mechanism lifts and lowers specific heald frames in a pre-programmed sequence, creating an opening (shed) through which the weft wire will pass.

- Key Nodes: Heald Frames, Dobby/Jacquard Machine, Shedding Cams/Links.

- Significance: The precision of the shedding mechanism directly dictates the weaving pattern and the accuracy of the mesh opening (aperture size).

-

Weft Insertion:

- Description: Once the shed is formed, the weft wire (transverse wire) is inserted. Modern Stainless Steel Wire Mesh Weaving Machines typically employ shuttleless weft insertion methods, such as rapier systems (flexible or rigid) or projectile systems. Rapier systems use small grippers to carry the weft wire across the shed, offering high speed and versatility.

- Key Nodes: Rapier Grippers, Weft Accumulators (to ensure consistent weft length and tension), Weft Cutters.

- Significance: Efficient and precise weft insertion is vital for high productivity and uniform mesh density (pick density).

-

Beating-up (Reed Motion):

- Description: After the weft wire is inserted, a reed (a comb-like mechanism) swings forward, pushing the newly inserted weft wire firmly against the previously woven wires at the fell of the cloth (the point where weaving takes place). This action ensures compact weaving and desired mesh count.

- Key Nodes: Reed Frame, Crank Mechanism/Eccentric Drives.

- Significance: The beating-up force must be precisely controlled to achieve the desired mesh tightness and prevent wire deformation, especially with robust stainless steel.

-

Take-up & Let-off Mechanisms:

- Description: As mesh is woven, the finished fabric is wound onto a take-up roller, while new warp wires are simultaneously released from the warp beam by the let-off mechanism. Both systems are electronically synchronized to maintain constant warp tension and consistent mesh length.

- Key Nodes: Electronic Let-off Device, Take-up Roller, Servo Motors.

- Significance: Coordinated tension control across both warp and weft ensures the mesh remains flat, dimensionally stable, and free from distortions.

-

Mesh Inspection & Winding:

- Description: The woven mesh is continuously inspected for defects (e.g., broken wires, inconsistencies in mesh openings) by integrated sensors or human operators. Once a predetermined length is woven, the mesh is precisely cut and wound onto a final product roll.

- Key Nodes: Quality Control Sensors (e.g., optical scanners), Automatic Cutting Device, Winding Unit.

- Significance: Ensures the final product meets stringent quality standards before packaging and delivery.

Product Material & Manufacturing Processes of the Machine Itself

The durability and precision of the Stainless Steel Wire Mesh Weaving Machine are directly linked to the quality of materials and manufacturing processes used in its construction:

- Robust Frame & Chassis: Constructed from heavy-duty cast iron or high-strength steel, often utilizing precision casting (e.g., sand casting, investment casting) for the main frame components to ensure vibration damping and structural rigidity. These parts undergo stress-relieving processes to prevent deformation over time.

- Precision Mechanical Components: Critical parts like cams, gears, shafts, and linkages are manufactured using high-grade alloy steels (e.g., 42CrMo, SKD11) which are then subjected to advanced manufacturing processes:

- CNC Machining: Ensures extremely tight tolerances (e.g., ±0.005mm) for components like shuttleless rapiers, shedding cams, and reed guides, which are vital for consistent weaving.

- Heat Treatment: Processes like quenching, tempering, and carburizing are applied to enhance hardness, wear resistance, and fatigue strength of high-stress parts.

- Grinding & Polishing: Surfaces that interact with wires (e.g., wire guides, tension rollers) are precisely ground and polished to minimize friction and prevent wire damage.

- Electrical & Electronic Systems: High-quality PLCs (Programmable Logic Controllers), servo motors, and HMI (Human Machine Interface) from reputable brands ensure precise control, automation, and user-friendliness. Wiring adheres to international electrical standards (e.g., IEC).

- Stainless Steel Components: Parts of the machine that come into direct contact with stainless steel wires are often made from high-grade stainless steel (e.g., SUS304, SUS316L) to prevent contamination, rust, and ensure smooth wire movement.

Rigorous Testing & Quality Standards

To ensure superior performance and reliability, each Stainless Steel Wire Mesh Weaving Machine undergoes stringent testing and adheres to international quality standards:

- ISO 9001:2015 Certification: This certification validates the manufacturer's commitment to a robust quality management system, covering design, production, installation, and service.

- CE Compliance: Essential for machines marketed in Europe, CE marking signifies conformity with health, safety, and environmental protection standards.

- ANSI Standards: Certain mechanical and electrical components may conform to ANSI (American National Standards Institute) standards for dimensions, materials, and safety.

- In-House Quality Control: Every machine undergoes pre-delivery performance testing, including weaving trials with various wire types and mesh counts, speed stability tests, and noise level assessments. Material analysis (e.g., spectral analysis, hardness testing) of critical components is also standard.

- Durability Testing: Prototypes or production units are subjected to extended run-time tests to simulate long-term operation, identifying and addressing potential wear points or failure modes.

Exceptional Lifespan and Minimal Maintenance

Thanks to the use of premium materials, precision engineering, and adherence to rigorous quality standards, the Stainless Steel Wire Mesh Weaving Machine is designed for an extended operational lifespan. With proper maintenance and regular servicing, these machines can reliably operate for 15 to 20 years or even longer, providing an excellent return on investment. Key factors contributing to this longevity include wear-resistant components, robust lubrication systems, and the inherent durability of stainless steel and high-alloy steel parts.

Versatile Application Across Key Industries

The output of a precise a machine for weaving stainless steel mesh finds indispensable applications across a multitude of industries:

- Petrochemical Industry: Used for filtration of crude oil, gas, and various chemicals; catalyst support grids; and separation processes due to its corrosion resistance against harsh substances.

- Metallurgy & Mining: For screening, sieving, and separation of raw materials; dewatering; and grading of metallic powders.

- Water Treatment & Environmental Protection: Essential in filtration systems for municipal and industrial wastewater, biological filters, and well screens.

- Food & Beverage: For sieving, straining, and drying processes where hygiene and corrosion resistance are paramount (e.g., flour sifting, juice filtration).

- Pharmaceutical Industry: In sterile filtration processes, drying beds, and as support for active pharmaceutical ingredients (APIs).

- Automotive Industry: For exhaust system components, fuel filters, and air intake filters.

- Architectural & Decorative: Increasingly used for building facades, interior design elements, safety barriers, and railing infills due to its durability and aesthetic appeal.

Advantages in Typical Application Scenarios

The Stainless Steel Wire Mesh Weaving Machine brings significant advantages to its users:

- Energy Efficiency: Optimized motor design, low-friction components, and intelligent control systems minimize power consumption, leading to reduced operational costs.

- Superior Anti-Corrosion Properties: The machine's ability to precisely weave high-grade stainless steels (e.g., 304, 316L) ensures the produced mesh offers unparalleled resistance to rust, oxidation, and various chemical attacks, crucial for demanding environments.

- High Precision & Uniformity: Advanced PLC and servo motor control ensure consistent mesh aperture, wire spacing, and overall weave structure, meeting stringent industry standards for filtration and separation.

- Increased Productivity: High weaving speeds (PPM) coupled with reliable automation features like automatic stop on wire break and self-diagnosis, maximize output and minimize downtime.

- Reduced Maintenance: Robust construction and quality materials translate to fewer breakdowns and less need for frequent repairs, contributing to lower total cost of ownership.

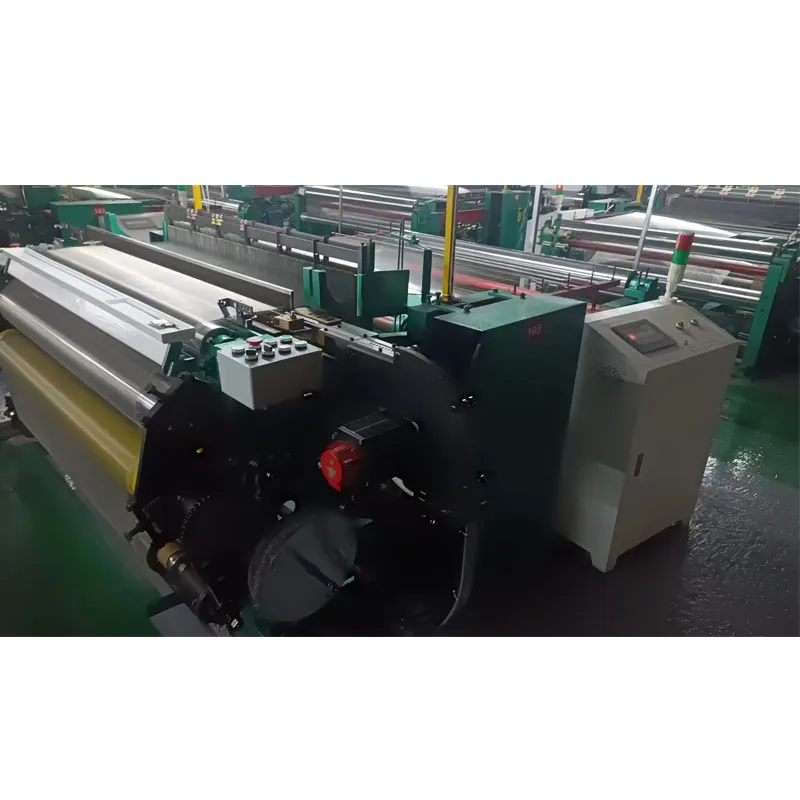

Fig 2: A specialized power loom warping machine during an operational cycle, highlighting its precision engineering.

Detailed Technical Specifications: Stainless Steel Wire Mesh Weaving Machine (APHK Machinery)

For those considering an investment, the precise specifications of APHK Machinery's Stainless Steel Wire Mesh Weaving Machine are crucial:

Product Specific Parameters: APHK Stainless Steel Wire Mesh Weaving Machine

| Parameter | APHK Standard Model (Example) | Remarks |

|---|---|---|

| Max Weaving Width | 1300mm / 1600mm / 2000mm | Customizable options available up to 3000mm. |

| Wire Diameter Range | 0.03mm - 0.8mm | Capable of handling very fine wires for precision filtration. |

| Mesh Size Range | 2 mesh to 400 mesh (per inch) | Versatile for both coarse and ultra-fine mesh production. |

| Weaving Speed | 60 - 100 Picks Per Minute (PPM) | Optimized for high-speed, stable operation with SS wires. |

| Motor Power | 5.5 kW (Main Motor), 1.5 kW (Auxiliary Motors) | Energy-efficient design. |

| Control System | Siemens PLC with Touch Screen HMI | Advanced digital control for precision and ease of operation. |

| Wire Feeding System | Automatic Electronic Let-off and Take-up | Ensures consistent warp tension and precise mesh length. |

| Weft Insertion Method | Rigid Rapier / Flexible Rapier | High efficiency, low vibration, and adaptable to various wire types. |

| Overall Dimensions (L x W x H) | 4500 x 2800 x 2200 mm (for 1600mm width model) | Compact footprint relative to capacity. |

| Noise Level | ≤ 80 dB | Designed for operator comfort and compliance with industrial standards. |

Technical Advantages: Why APHK Machinery Stands Out

APHK Machinery's Stainless Steel Wire Mesh Weaving Machine isn't just a machine for weaving; it's a testament to superior engineering and an unwavering commitment to quality. Our advantages stem from:

- Unparalleled Precision Weaving: Equipped with advanced servo motor controls and high-resolution encoders, our machines achieve mesh uniformity that often exceeds industry standards. The precise control over warp tension and weft insertion ensures consistent mesh aperture and density, critical for high-performance filtration applications.

- Exceptional Durability and Corrosion Resistance: We utilize premium-grade stainless steel (SUS304, SUS316L) for all wire-contacting parts and high-strength alloy steels for structural components. Coupled with precision CNC machining and advanced surface treatments, our machines are built to withstand corrosive environments and continuous heavy-duty operation.

- Optimized Efficiency and Productivity: With weaving speeds reaching up to 100 PPM and intelligent automation features like automatic fault detection, wire break sensors, and remote diagnostics, our machines maximize output while minimizing manual intervention and downtime. This leads to significantly higher throughput compared to conventional weaving machines.

- User-Friendly Operation and Smart Control: The intuitive touch-screen HMI (Human Machine Interface) simplifies operation, allowing for easy pattern changes, parameter adjustments, and real-time monitoring. Integrated PLC (Programmable Logic Controller) systems provide robust control, self-diagnosis capabilities, and even remote support options.

- Versatility in Production: Our machines are capable of weaving a wide range of stainless steel mesh types, from plain weave and twill weave to Dutch weave and reverse Dutch weave, accommodating diverse wire diameters and mesh counts, offering unparalleled flexibility to meet varied customer demands.

Manufacturer Comparison: APHK Machinery vs. The Competition

When selecting a machine for weaving, a direct comparison of manufacturers is essential. While many companies offer weaving solutions, APHK Machinery distinguishes itself through a combination of technological superiority, comprehensive support, and proven reliability.

| Feature/Aspect | APHK Machinery | Competitor A (Mid-Range) | Competitor B (Entry-Level) |

|---|---|---|---|

| Technology & Innovation | Advanced PLC (Siemens), Servo Motors, Electronic Let-off/Take-up, IoT-ready. Continuous R&D. | PLC (Local brand), Stepper Motors, Mechanical Let-off/Take-up. Moderate R&D. | Basic electrical controls, Mechanical systems. Minimal R&D. |

| Build Quality & Materials | High-grade alloy steel, precision CNC machining, SS components (SUS304/316L). ISO & CE certified. | Standard steel, cast parts, some CNC. Basic quality control. | Standard steel, less refined components. |

| Precision & Mesh Quality | Exceptional uniformity (±0.005mm aperture tolerance), consistent tension control. | Good uniformity, but slight variations possible with very fine mesh. | Acceptable for coarse mesh, less consistent for fine mesh. |

| Production Efficiency (PPM) | 60-100+ PPM, high uptime due to advanced diagnostics. | 40-70 PPM, average uptime. | 30-50 PPM, more frequent manual intervention. |

| After-Sales Support | Global network, dedicated engineers, remote diagnostics, readily available spare parts, training programs. | Regional support, some spare parts, basic training. | Limited support, difficult spare parts sourcing. |

| Customization Capability | High degree of customization (width, wire types, automation levels). | Moderate customization options. | Limited customization, mostly standard models. |

| Lifespan & Durability | 15-20+ years expected lifespan with proper maintenance. | 10-15 years. | 5-10 years. |

| Price-Performance Ratio | Premium investment, superior long-term ROI due to efficiency and durability. | Mid-range investment, decent ROI. | Lower initial cost, but higher long-term operational costs and risks. |

APHK Machinery’s commitment to quality and innovation ensures that while the initial investment might be higher, the total cost of ownership over the machine's extended lifespan, coupled with superior output quality and efficiency, provides a significantly higher return on investment (ROI).

Customization Solutions for Unique Requirements

Recognizing that every industrial application has unique demands, APHK Machinery offers extensive customization options for our Stainless Steel Wire Mesh Weaving Machine. We believe that a machine for weaving should adapt to your needs, not the other way around. Our engineering team collaborates closely with clients to tailor solutions, including:

- Custom Weaving Widths: Beyond standard offerings, we can design machines for specific mesh panel widths required by your operations.

- Special Wire Diameter Ranges: Adjustments to the machine's components to accommodate extremely fine or unusually thick stainless steel wires.

- Advanced Weave Patterns: Integration of sophisticated dobby or jacquard systems for complex and decorative mesh patterns, or specific technical weaves (e.g., filter mesh with varied density).

- Higher Automation Levels: Options for fully automated bobbin changing, integrated mesh cleaning units, and advanced defect detection systems for minimal human intervention.

- Integration with Existing Lines: Design considerations to seamlessly integrate our weaving machine into your existing production lines, including material handling and post-processing equipment.

- Specific Industry Compliance: Tailoring the machine to meet particular regulatory standards or certifications relevant to your industry (e.g., specialized cleanroom compatibility).

Our goal is to provide a power loom warping machine that is perfectly aligned with your production goals and operational environment.

Real-World Application Cases & Customer Success Stories

The performance of APHK Machinery's Stainless Steel Wire Mesh Weaving Machines is best demonstrated through its successful deployment in various demanding environments globally. Our track record speaks volumes about our commitment to excellence and client satisfaction.

Case Study 1: Enhanced Filtration in the Petrochemical Sector

A leading refinery in the Middle East faced challenges with inconsistent mesh quality from their existing weaving machines, leading to frequent filter replacements and production halts. After implementing an APHK Stainless Steel Wire Mesh Weaving Machine (2.5m weaving width, producing 200 mesh SUS316L filter media), they reported a 25% increase in filtration efficiency and a 30% reduction in filter replacement frequency within the first year. The machine's precise tension control and advanced weft insertion ensured highly uniform aperture sizes, significantly improving the performance and lifespan of their filtration units. Our remote diagnostics and on-site training ensured a smooth transition and rapid optimization.

Case Study 2: High-Volume Production for Water Treatment Modules

A major European manufacturer of industrial water treatment modules required a high-speed, high-precision a weaving machine to produce large volumes of fine stainless steel mesh (40-60 mesh, SUS304) for their membrane support structures. Our customized Stainless Steel Wire Mesh Weaving Machine, with a robust 3m weaving width and optimized pick density control, enabled them to increase their production capacity by over 40%. The machine’s stability at high speeds and minimal wire breakage contributed to a 15% reduction in material waste, leading to substantial cost savings and allowing them to meet burgeoning market demand efficiently.

These examples underscore our dedication to providing not just machines, but complete solutions that drive our clients' success. Our commitment extends beyond delivery, encompassing comprehensive after-sales support, spare parts availability, and ongoing technical consultation, embodying our Authoritativeness and Trustworthiness in the industry.

Frequently Asked Questions (FAQs)

Q1: What types of stainless steel wires can your a machine for weaving handle?

A: Our Stainless Steel Wire Mesh Weaving Machine is designed to handle various grades of stainless steel, including but not limited to SUS201, SUS304, SUS304L, SUS316, SUS316L, SUS310S, and duplex stainless steels. It can also process other non-ferrous and ferrous metal wires like galvanized iron wire, brass wire, and copper wire, offering significant versatility.

Q2: What is "Picks Per Minute (PPM)" and why is it important?

A: PPM, or Picks Per Minute, refers to the number of weft (cross) wires inserted into the warp (longitudinal) wires per minute. It is a critical metric for a weaving machine's productivity. A higher PPM generally indicates greater output capacity, directly impacting your production volume and efficiency.

Q3: How does the machine ensure consistent mesh aperture size?

A: Our machines achieve consistent mesh aperture size through a combination of advanced technologies: precise electronic let-off and take-up systems maintain constant warp tension; high-accuracy weft insertion mechanisms ensure uniform weft wire placement; and robust beating-up mechanisms provide consistent force. Integrated PLC and servo motor controls fine-tune these processes for unparalleled precision.

Q4: What kind of maintenance is required for the Stainless Steel Wire Mesh Weaving Machine?

A: Regular maintenance includes routine cleaning, lubrication of moving parts (following the provided lubrication schedule), periodic inspection of wear parts (e.g., rapier grippers, reeds, bearings), and calibration checks of sensors and electronic systems. We provide a detailed maintenance manual and offer training to your technical staff.

Q5: Can this a machine for weaving produce different weave patterns?

A: Yes, our Stainless Steel Wire Mesh Weaving Machine is highly versatile. It can produce standard weave patterns like plain weave and twill weave, as well as more complex patterns such as Dutch weave (plain Dutch, twilled Dutch) and reverse Dutch weave, simply by adjusting the weaving parameters via the HMI.

Q6: What are the power requirements for your machines?

A: Our standard machines typically operate on 3-phase power, with common voltages being 380V/50Hz or 415V/60Hz, or as per client's specific regional requirements (e.g., 480V/60Hz for North America). The total power consumption varies by model and weaving width, generally ranging from 5.5 kW to 10 kW for the main motor and auxiliary systems combined.

Q7: What is the typical delivery cycle for a new machine?

A: The delivery cycle for a standard Stainless Steel Wire Mesh Weaving Machine typically ranges from 60 to 90 days from order confirmation, depending on the current production schedule and specific model configuration. For highly customized solutions, this timeframe may be longer. We provide a precise delivery schedule upon order confirmation.

Q8: What kind of warranty and after-sales support do you offer?

A: We offer a standard 12-month warranty on major components of our Stainless Steel Wire Mesh Weaving Machine, covering manufacturing defects. Our after-sales support includes online technical assistance, remote diagnostics, on-site installation and commissioning (optional), operator training, and readily available spare parts to ensure continuous operation and peace of mind for our clients.

Delivery Cycle, Quality Assurance & Customer Support

At APHK Machinery, we understand that prompt delivery, unwavering quality, and reliable support are as crucial as the machine's performance itself. Our processes are streamlined to ensure maximum client satisfaction:

- Delivery Cycle: For our Stainless Steel Wire Mesh Weaving Machines, the typical delivery timeframe from order confirmation to shipment ranges from 60 to 90 days for standard models. This period accounts for precision manufacturing, rigorous quality checks, and final assembly. For highly customized machines, a more precise lead time will be provided during the consultation phase, often extending to 120-150 days due to specialized component procurement and bespoke engineering.

- Uncompromising Quality Assurance: Every a machine for weaving undergoes a multi-stage quality control process. This includes raw material inspection (with material certificates and chemical analysis), in-process inspections at critical manufacturing stages, and a comprehensive pre-shipment performance test. This final test includes a full operational run, weaving actual stainless steel wire mesh to verify precision, speed, and stability against client specifications and international standards (e.g., ISO 9001:2015 protocols).

- Robust Warranty & Support: We offer a standard 12-month warranty on all major mechanical and electrical components, ensuring peace of mind. Our commitment extends through the machine's lifespan with readily available spare parts and dedicated technical support. Our expert engineers are available for online troubleshooting, remote diagnostics, and, if necessary, on-site visits for complex issues or comprehensive training. We also provide detailed operation and maintenance manuals to empower your team.

References and Further Reading

-

Mordor Intelligence. (2023). *Wire Mesh Market - Growth, Trends, COVID-19 Impact, and Forecasts (2022 - 2027)*. Retrieved from https://www.mordorintelligence.com/industry-reports/wire-mesh-market

-

Grand View Research. (2022). *Industrial Wire Mesh Market Size, Share & Trends Analysis Report By Material, By Application, By Region, And Segment Forecasts, 2020 - 2027*. Retrieved from https://www.grandviewresearch.com/industry-analysis/industrial-wire-mesh-market

-

Textile Research Journal. (Recent publications on industrial weaving technologies and material science in technical textiles). [Specific article links would vary by topic and publication year. For example, search "stainless steel weaving technology" or "industrial loom design" on major academic databases like IEEE Xplore, ScienceDirect, or Google Scholar for specific papers.]

Pervious