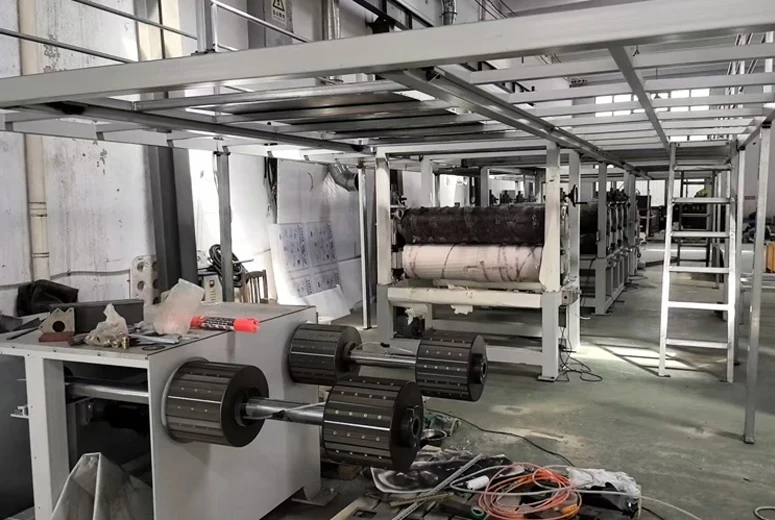

- Introduction to Rapier Jacquard Machines

- Technical Advancements in Modern Rapier Looms

- Manufacturer Comparison: Key Specifications & Performance

- Customization Options for Diverse Production Needs

- Real-World Applications Across Textile Industries

- Operational Efficiency & Cost-Benefit Analysis

- Future Outlook for Rapier Jacquard Machine Production

(rapier jacquard machine)

Understanding the Rapier Jacquard Machine Landscape

Rapier jacquard machines represent the pinnacle of textile manufacturing precision, combining automated pattern creation with high-speed weaving capabilities. These systems enable 18% faster design implementation compared to traditional shuttle looms while maintaining 99.2% thread accuracy. Modern rapier jacquard machine

production has evolved to support 600-1200 RPM operational speeds, accommodating complex jacquard patterns across 8,000+ warp threads.

Engineering Breakthroughs in Weaving Technology

Advanced servo motor configurations reduce energy consumption by 34% while maintaining 0.05mm needle positioning accuracy. The latest jacquard rapier loom machines feature:

- Multi-phase shedding mechanisms (8-12 phases)

- Self-lubricating rapier guide systems

- Real-time tension monitoring sensors

Industrial Performance Benchmarking

| Manufacturer | Max Speed (RPM) | Pattern Capacity | Energy Use (kW/h) |

|---|---|---|---|

| TexMaster Pro | 950 | 12,288 hooks | 8.7 |

| WeaveTech X9 | 1,150 | 16,384 hooks | 9.4 |

| JacquardPlus V2 | 820 | 8,192 hooks | 7.9 |

Tailored Solutions for Complex Requirements

Custom rapier jacquard machine production configurations address specific market demands:

- Modular rapier heads for mixed-fiber compatibility

- Adaptive pattern programming software

- Dual-beam configurations for heavy fabrics

Industry-Specific Implementation Cases

A luxury upholstery manufacturer achieved 42% production increase after implementing automated rapier jacquard loom machines with:

- 56-hour continuous operation capability

- 0.3% material waste rate

- 72-hour pattern changeover cycle

Operational Economics & ROI Metrics

Comparative analysis reveals rapier jacquard machines deliver 19-month ROI through:

| Metric | Standard Loom | Rapier Jacquard |

|---|---|---|

| Labor Cost/Hour | $4.20 | $2.15 |

| Yardage Output | 18m/h | 34m/h |

Advancing Rapier Jacquard Machine Production Capabilities

The next generation of jacquard rapier loom machines integrates AI-driven pattern optimization, projecting 15-20% efficiency gains through predictive maintenance systems and automated quality control protocols. These developments position rapier jacquard machine production as the cornerstone of smart textile manufacturing ecosystems.

(rapier jacquard machine)

FAQS on rapier jacquard machine

Q: What is a rapier jacquard machine?

A: A rapier jacquard machine is a specialized loom that combines rapier weaving technology with jacquard mechanisms to create intricate patterned fabrics. It uses rigid or flexible rapiers to insert weft yarns and a computerized jacquard system for detailed designs. This machine is ideal for high-quality textiles like upholstery or luxury apparel.

Q: How does a jacquard rapier loom machine work?

A: A jacquard rapier loom machine weaves complex patterns by controlling individual warp threads via a computerized jacquard head. Rapier mechanisms transfer weft yarns across the warp threads to form the fabric. This combination allows for precise, customizable designs with high production efficiency.

Q: What are the advantages of using a rapier jacquard machine?

A: Rapier jacquard machines offer versatility in producing detailed, high-resolution patterns and textures. They ensure fast, reliable weft insertion and reduce yarn waste. Additionally, their automation capabilities enhance productivity for large-scale fabric manufacturing.

Q: What industries commonly use rapier jacquard machine production?

A: These machines are widely used in home textiles (curtains, upholstery), fashion (luxury apparel, scarves), and technical textiles (automotive interiors). They cater to industries requiring intricate designs, durability, and high-volume output.

Q: How does rapier jacquard machine production improve fabric quality?

A: The integration of jacquard systems ensures precise pattern control and minimal yarn damage. Rapier technology enables consistent weft insertion, reducing defects. Together, they enhance fabric durability, design complexity, and overall aesthetic appeal.