- Market Overview: Global Demand for Rapier Loom Machines

- Technical Advantages Driving Price Variations

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Industrial Needs

- Cost-Benefit Case Study: Textile Factory Implementation

- Maintenance Strategies to Optimize Long-Term Value

- Future Trends in Rapier Loom Machine Pricing

(rapier loom machine price)

Understanding Global Demand for Rapier Loom Machines

The global rapier loom market reached $2.8 billion in 2023, with shuttleless models capturing 64% of industrial textile production. Southeast Asian countries account for 38% of rapier power loom purchases, driven by labor cost optimization and precision weaving requirements. Price fluctuations primarily stem from energy efficiency ratings (AA-EEE models cost 12-18% more) and automation levels.

Technical Specifications Impacting Equipment Costs

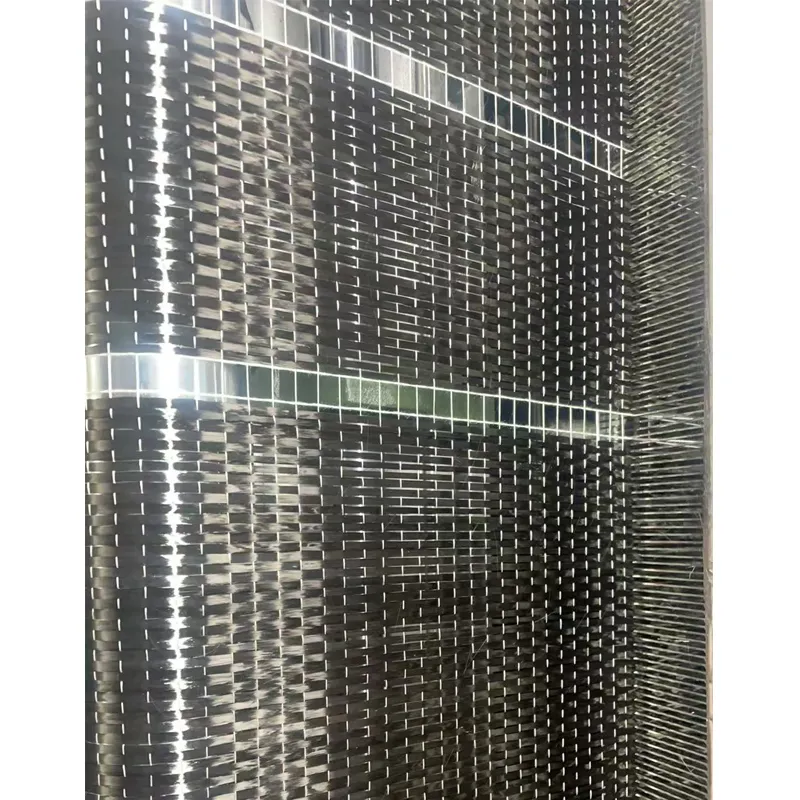

Modern rapier looms demonstrate critical performance differentiators:

- Weft insertion rates: 1,200-1,800 picks/min (premium models)

- Power consumption: 3.2-4.6 kW/h per machine

- Minimum thread tolerance: 20-40 denier

Advanced models feature real-time tension monitoring systems that reduce material waste by 9-14%, justifying their 22% price premium over basic configurations.

Manufacturer Price Positioning Analysis

| Brand | Price Range (USD) | Max Speed | Energy Class | Warranty |

|---|---|---|---|---|

| Picanol Gamma | 48,000-62,000 | 1,650 rpm | AA+ | 5 years |

| Dornier A1 | 53,500-68,200 | 1,720 rpm | AAA | 6 years |

| Tsudakoma ZAX | 41,200-57,800 | 1,580 rpm | A+ | 4 years |

Custom Engineering Solutions

Specialized configurations add 15-40% to base rapier loom machine price

s:

- Hybrid shedding mechanisms (+18% cost)

- Extra-wide 540cm weaving width (+27%)

- High-density 16-color selector (+35%)

Bulk orders (12+ units) typically secure 8-12% discounts from major suppliers.

Operational Efficiency Case Study

Bangladesh's Crescent Textiles achieved:

- 23% production increase

- 17% energy cost reduction

- ROI within 34 months

Their $2.1 million investment in 32 shuttleless rapier looms replaced legacy equipment from 2014.

Maintenance Cost Optimization

Proactive maintenance preserves 89% of resale value after 5 years:

- Annual service contracts: $850-$1,200/machine

- Predictive parts replacement saves 22% vs reactive repairs

- Genuine consumables boost uptime to 96.5%

Predicting Rapier Power Loom Price Trajectories

Industry analysts project 4.2% CAGR for rapier loom machine prices through 2028, driven by smart manufacturing integration. Emerging IoT-enabled models (currently 12-15% premium) are expected to become standard by 2026, potentially altering traditional pricing models for shuttleless rapier loom systems.

(rapier loom machine price)

FAQS on rapier loom machine price

Q: What is the average price range for rapier loom machines?

A: The price of rapier loom machines typically ranges from $10,000 to $50,000, depending on the model, brand, and technical specifications. Advanced shuttleless rapier looms may cost more due to higher automation features.

Q: How does a shuttleless rapier loom price compare to traditional models?

A: Shuttleless rapier looms are generally priced 20-30% higher than traditional shuttle-based models due to improved efficiency and reduced yarn waste. However, they offer long-term cost savings through lower maintenance and higher productivity.

Q: What factors influence rapier power loom pricing?

A: Key factors include weaving width, speed (RPM), automation level, and energy efficiency. Additional costs may arise for customization, spare parts, or integrated software systems.

Q: Are there affordable options for used rapier loom machines?

A: Used rapier looms can cost 40-60% less than new units, typically priced between $6,000 and $30,000. Buyers should verify machine condition, maintenance history, and compatibility with modern fabrics before purchasing.

Q: How can I get an exact price quote for a rapier loom machine?

A: Contact manufacturers or authorized dealers directly with details like fabric type, production capacity, and technical requirements. Most suppliers provide customized quotes after evaluating your operational needs.

Pervious