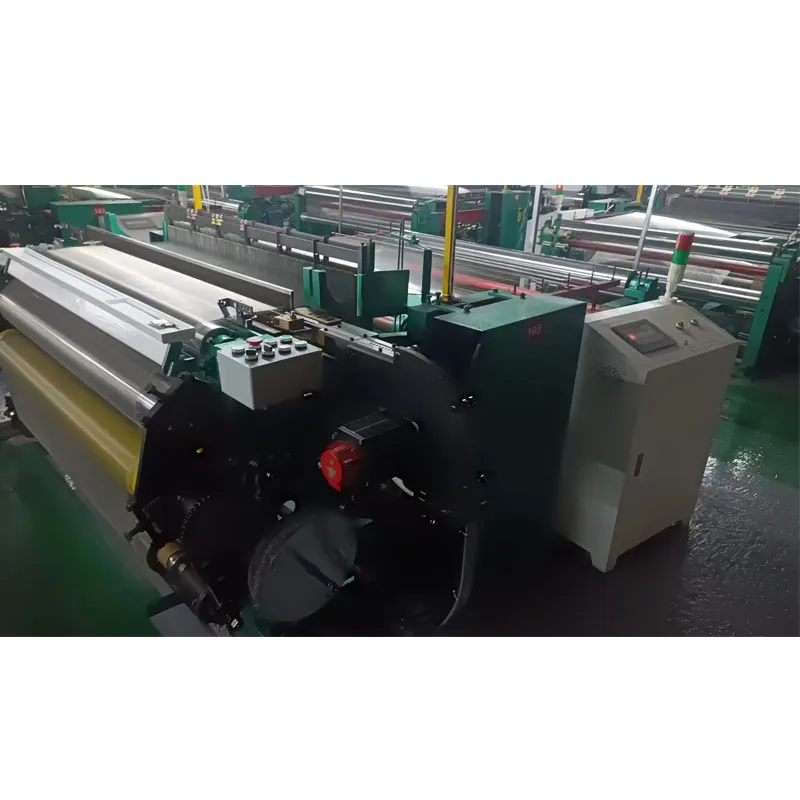

Stainless Steel Wire Mesh Weaving Machine: High-Efficiency Solution for Industrial Applications

As a leading manufacturer in the wire mesh machinery industry, Anping Hongke Wire Mesh Machinery Factory introduces its advanced Stainless Steel Wire Mesh Weaving Machine, designed to revolutionize industrial wire mesh production. This cutting-edge equipment combines precision engineering with innovative technology to deliver unmatched efficiency and quality. Whether you're in construction, agriculture, or manufacturing, our machine is engineered to meet your most demanding requirements.

With Anping Hongke Wire Mesh Machinery Factory's commitment to excellence, this machine stands out as a reliable solution for producing high-quality stainless steel wire mesh. Its robust design ensures durability, while the advanced weaving technology guarantees consistent results. Discover how this machine can transform your production process and elevate your business to new heights.

Product Overview and Core Features

The Stainless Steel Wire Mesh Weaving Machine is a specialized industrial equipment designed for efficiently weaving stainless steel wires into intricate mesh patterns. This machine is a vital component in the production of wire mesh used across various sectors, including construction, filtration, and automotive industries. Its advanced features ensure high-speed operation, precision, and reliability, making it an ideal choice for manufacturers seeking to enhance productivity and reduce costs.

Key features of the machine include:

- High-Speed Weaving Technology: The machine utilizes advanced weaving mechanisms to produce wire mesh at a significantly faster rate compared to traditional methods.

- Precision Engineering: Each component is designed with meticulous attention to detail, ensuring accurate mesh patterns and consistent quality.

- Durable Construction: Built with high-quality materials, the machine is engineered to withstand heavy-duty operations and maintain performance over time.

- User-Friendly Interface: The intuitive control panel allows operators to easily adjust settings and monitor the weaving process, enhancing overall efficiency.

By integrating these features, the Stainless Steel Wire Mesh Weaving Machine not only improves production efficiency but also reduces labor costs and minimizes material waste. This makes it a cost-effective solution for businesses looking to optimize their manufacturing processes.

Market Demand and Industry Challenges

The demand for stainless steel wire mesh has been steadily increasing across various industries due to its superior strength, corrosion resistance, and versatility. However, traditional weaving methods often face challenges such as low production efficiency, inconsistent quality, and high operational costs. These issues can hinder the growth of manufacturers and limit their ability to meet market demands.

According to industry reports, the global wire mesh market is projected to grow at a CAGR of 4.5% from 2023 to 2030, driven by the rising need for durable and high-performance materials in construction and industrial applications. This growth highlights the importance of adopting advanced machinery like the Stainless Steel Wire Mesh Weaving Machine to stay competitive.

One of the primary challenges in the wire mesh industry is the need for precision and consistency in production. Traditional methods often result in uneven mesh patterns, which can lead to quality issues and customer dissatisfaction. Additionally, the labor-intensive nature of manual weaving processes increases operational costs and reduces overall productivity.

The Stainless Steel Wire Mesh Weaving Machine addresses these challenges by offering a fully automated solution that ensures precise and consistent mesh production. Its advanced technology eliminates the need for manual intervention, reducing the risk of errors and improving overall efficiency. This not only enhances product quality but also enables manufacturers to meet tight deadlines and deliver high-quality products to their customers.

Company Expertise and Technological Innovation

Anping Hongke Wire Mesh Machinery Factory has established itself as a leader in the wire mesh machinery industry, with over a decade of experience in developing innovative solutions for manufacturers worldwide. The company's commitment to research and development has enabled it to create cutting-edge machines that set industry standards for performance and reliability.

With a dedicated team of engineers and technicians, Anping Hongke continuously invests in technological advancements to improve its products. The Stainless Steel Wire Mesh Weaving Machine is a testament to the company's expertise, incorporating the latest innovations in automation and precision engineering. This machine is designed to meet the evolving needs of the industry, providing manufacturers with a competitive edge in a rapidly changing market.

The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every machine meets the highest standards of performance and durability. By leveraging its extensive industry knowledge and technical capabilities, Anping Hongke has successfully supplied its products to clients in over 50 countries, earning a reputation for excellence and customer satisfaction.

Product Performance and Customer Testimonials

Manufacturers who have adopted the Stainless Steel Wire Mesh Weaving Machine have reported significant improvements in production efficiency and product quality. One of the key benefits of this machine is its ability to produce wire mesh at a faster rate without compromising on precision. This has allowed businesses to increase their output and meet growing market demands more effectively.

Customer testimonials highlight the machine's reliability and ease of use. For instance, a client from the construction industry noted, "Since implementing the Stainless Steel Wire Mesh Weaving Machine, our production time has been reduced by 40%, and the quality of our products has improved significantly. This machine has become an essential part of our operations."

Another user from the filtration industry shared, "The precision and consistency of the mesh produced by this machine have greatly enhanced our product performance. We have seen a noticeable increase in customer satisfaction, and our business has grown substantially since we upgraded to this equipment."

These success stories underscore the value of the Stainless Steel Wire Mesh Weaving Machine in driving business growth and operational efficiency. Its ability to deliver high-quality results consistently makes it a preferred choice for manufacturers seeking to optimize their production processes.

Usage Guidelines and Customization Options

To ensure optimal performance and longevity, it is essential to follow the recommended usage guidelines for the Stainless Steel Wire Mesh Weaving Machine. Proper maintenance and operation can significantly enhance the machine's efficiency and reduce downtime. Here are some key recommendations:

- Regular Maintenance: Schedule routine inspections and maintenance to keep the machine in peak condition. This includes checking for wear and tear, lubricating moving parts, and ensuring all components are functioning correctly.

- Operator Training: Provide comprehensive training to operators to ensure they understand the machine's features and can operate it efficiently. This helps prevent accidents and ensures consistent production quality.

- Material Compatibility: Use high-quality stainless steel wires that are compatible with the machine's specifications. This ensures optimal weaving results and minimizes the risk of machine damage.

In addition to standard configurations, Anping Hongke Wire Mesh Machinery Factory offers customization options to meet specific production requirements. Whether you need adjustments to the machine's size, speed, or weaving patterns, the company's team of experts can provide tailored solutions to suit your unique needs.

Safety and Environmental Compliance

The Stainless Steel Wire Mesh Weaving Machine is designed with safety and environmental compliance in mind. The machine adheres to international safety standards, ensuring a secure working environment for operators. Its advanced safety features, such as emergency stop buttons and protective guards, minimize the risk of accidents and promote safe operation.

Furthermore, the machine is built with eco-friendly materials and energy-efficient technology, reducing its environmental impact. This aligns with the growing demand for sustainable manufacturing practices and helps businesses meet regulatory requirements. By choosing this machine, manufacturers can contribute to a greener future while maintaining high production standards.

Packaging and Logistics

At Anping Hongke Wire Mesh Machinery Factory, we understand the importance of secure and efficient transportation for industrial equipment. The Stainless Steel Wire Mesh Weaving Machine is packaged using high-quality materials to protect it during transit. Each unit is carefully wrapped and secured to prevent damage, ensuring it arrives at your facility in perfect condition.

We offer flexible shipping options to accommodate your specific needs. Whether you require standard delivery or expedited shipping, our logistics team will work closely with you to ensure timely and reliable delivery. For international clients, we provide comprehensive support with customs documentation and shipping arrangements, making the process seamless and hassle-free.

Customer Support and After-Sales Services

At Anping Hongke Wire Mesh Machinery Factory, we are committed to providing exceptional customer support throughout the entire lifecycle of the Stainless Steel Wire Mesh Weaving Machine. Our dedicated support team is available to assist with any inquiries, technical issues, or maintenance requirements. We offer 24/7 customer service to ensure that you receive timely assistance whenever you need it.

In addition to technical support, we provide comprehensive training programs to help operators familiarize themselves with the machine's features and functionalities. This ensures that you can maximize the machine's potential and achieve optimal results. Our after-sales services also include on-site visits and remote diagnostics, allowing us to address any issues promptly and efficiently.

Contact Us for More Information

Ready to elevate your manufacturing capabilities? Contact Anping Hongke Wire Mesh Machinery Factory today to learn more about the Stainless Steel Wire Mesh Weaving Machine and how it can benefit your business. Our team of experts is here to provide personalized assistance and answer any questions you may have.

For more details, visit our company website or reach out to us directly at info@aphkmachinery.com. We look forward to partnering with you to achieve your production goals and drive your business forward.

Q&A: Frequently Asked Questions

1. What is the production speed of the Stainless Steel Wire Mesh Weaving Machine?

The Stainless Steel Wire Mesh Weaving Machine is designed to operate at high speeds, significantly increasing production efficiency. The exact speed may vary depending on the specific requirements and settings, but it is engineered to deliver consistent and rapid results.

2. Can the machine be customized to suit different production needs?

Yes, Anping Hongke Wire Mesh Machinery Factory offers customization options to meet specific production requirements. Our team of experts can tailor the machine's specifications, including size, speed, and weaving patterns, to suit your unique needs.

3. What kind of maintenance is required for the machine?

Regular maintenance is essential to ensure the machine's optimal performance. This includes routine inspections, lubrication of moving parts, and checking for wear and tear. Our team provides detailed maintenance guidelines to help you keep the machine in excellent condition.

4. Is the machine environmentally friendly?

Yes, the Stainless Steel Wire Mesh Weaving Machine is built with eco-friendly materials and energy-efficient technology, minimizing its environmental impact. This aligns with the growing demand for sustainable manufacturing practices.

5. What support is available after purchasing the machine?

We provide comprehensive after-sales support, including 24/7 customer service, technical assistance, and on-site visits. Our team is dedicated to ensuring that you receive the necessary guidance and support to maximize the machine's performance.

Conclusion

The Stainless Steel Wire Mesh Weaving Machine from Anping Hongke Wire Mesh Machinery Factory is a reliable and efficient solution for manufacturers seeking to enhance their production processes. With its advanced technology, precision engineering, and customization options, this machine is designed to meet the evolving needs of the industry. By investing in this equipment, businesses can achieve higher productivity, reduce costs, and deliver high-quality products to their customers. Explore our website to learn more about this innovative solution and how it can benefit your operations.