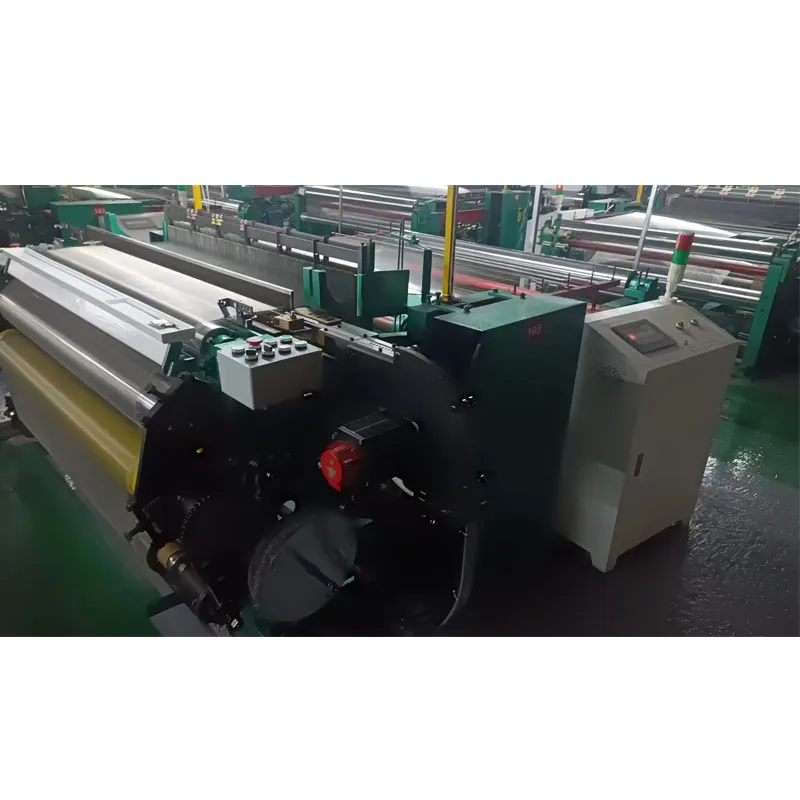

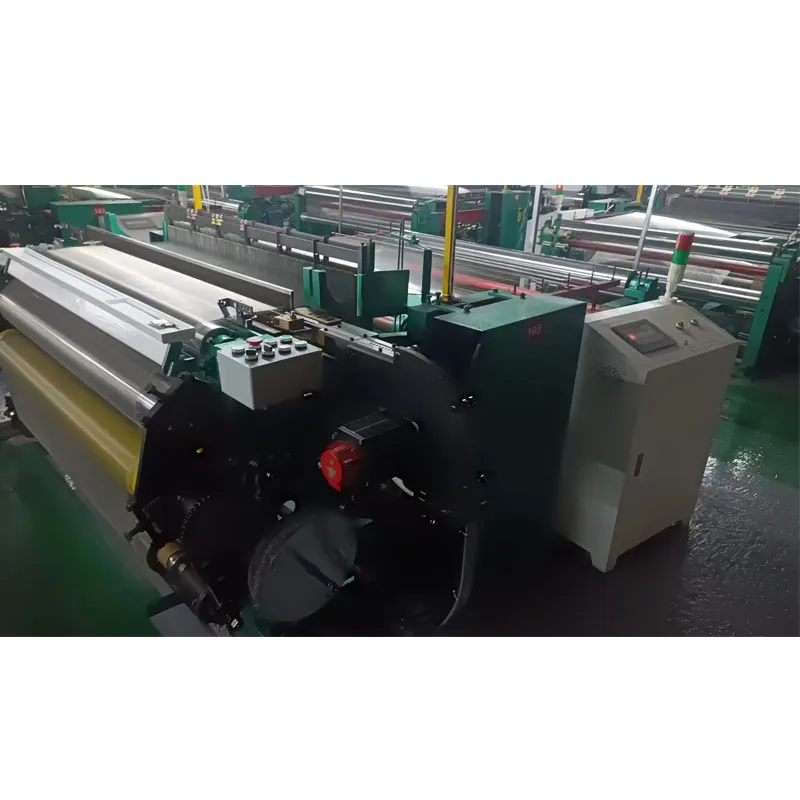

Stainless Steel Wire Mesh Weaving Machine: Precision, Versatility, and Industrial Excellence

The Stainless Steel Wire Mesh Weaving Machine represents a pinnacle of innovation in textile and industrial manufacturing. Designed for precision and adaptability, this machine is engineered to produce high-quality wire mesh with exceptional efficiency. Whether you're in construction, filtration, or automotive industries, this machine offers a robust solution to meet demanding production requirements. In this article, we will explore its core features, technical specifications, applications, and the company behind its development—Anping Hongke Wire Mesh Machinery Factory.

Product Functionality: Precision Weaving with Full PLC Control

The Stainless Steel Wire Mesh Weaving Machine is equipped with a full PLC (Programmable Logic Controller) system, enabling seamless adjustment of mesh patterns and dimensions. This advanced control mechanism ensures that operators can customize the weaving process to suit specific project needs. The machine supports multiple weaving techniques, including plain weaving and four-shafts twill weaving, with optional five-shafts configurations for specialized applications. This versatility makes it ideal for producing intricate mesh structures used in filtration systems, architectural designs, and industrial sieves.

One of the standout features is its weaving width, which ranges from 1000 to 2000mm. This wide range allows for the production of large-scale mesh panels, while reinforced structural components ensure stability even at maximum widths. The machine's ability to handle wire diameters up to 0.6mm further expands its utility, accommodating both fine and coarse mesh requirements.

Technical Specifications: Engineering Excellence

Below is a detailed specification table outlining the Stainless Steel Wire Mesh Weaving Machine's technical capabilities:

| Technical Parameter | Details |

|---|---|

| Wire Material | Iron, stainless steel, spring steel, copper, brass, bronze, aluminum, plastic asbestos |

| Picking Speed | Adjustable via frequency control; electromagnetic motor drive at 950r.p.m. |

| Beaming Drive | Chain-driven from the main driving clutch |

| Beaming Speed | Approximately 25m/min (82ft/min) |

| Stopping Devices | Warp and weft stopping systems with 220V A.C. and 24V secondary power |

| Weaving Reed Measurements | Overall height: 70mm; reed slot: 7mm and 10mm with 1.1mm thickness plate |

| Maximum Reed Length | Approximately weaving width + 60mm |

| Heddle Measurements | Hole center distance: 173 or 200mm; heddles nos. 2, 4, and 5 |

| Company | Anping Hongke Wire Mesh Machinery Factory |

Key Advantages: Why Choose This Machine?

The Stainless Steel Wire Mesh Weaving Machine stands out for its combination of precision, durability, and adaptability. Here are its key advantages:

- Full PLC Control: Enables real-time adjustments for mesh patterns and dimensions, ensuring consistent quality.

- Wide Weaving Width: Supports large-scale production with reinforced structures for stability.

- Multi-Functionality: Capable of plain weaving, four-shafts twill, and specialized five-shafts configurations.

- High Precision: Wire diameter range up to 0.6mm ensures versatility for diverse applications.

- Energy Efficiency: Electromagnetic motor drive and friction clutch optimize power usage.

Applications: From Construction to Advanced Filtration

This machine's versatility makes it suitable for a wide range of industries. In construction, it is used to produce wire mesh for reinforcing concrete and creating architectural facades. In filtration systems, its precision ensures the production of fine mesh for industrial and environmental applications. The automotive sector benefits from its ability to create durable mesh for air filters and heat shields. Additionally, the machine's compatibility with multiple materials—such as stainless steel, copper, and aluminum—makes it a preferred choice for manufacturers requiring corrosion-resistant components.

Company Background: Anping Hongke Wire Mesh Machinery Factory

Founded in Anping Hongke Wire Mesh Machinery Factory, this company has established itself as a leader in the production of industrial machinery. Located in Hebei Province, China, the factory specializes in wire mesh machinery and has built a reputation for delivering high-quality, reliable equipment. With years of experience in the industry, Anping Hongke combines traditional craftsmanship with modern technology to meet global demand. Their commitment to innovation and customer satisfaction is evident in the design and performance of the Stainless Steel Wire Mesh Weaving Machine.

Expertise and Authority: Aligning with Industry Standards

The Stainless Steel Wire Mesh Weaving Machine aligns with industry standards for precision and efficiency, reflecting the expertise of its manufacturer. According to the National Institute of Standards and Technology (NIST), "Precision in manufacturing is critical for ensuring product consistency and performance across industries" (NIST, 2025). Anping Hongke's focus on high-accuracy control systems and durable materials directly supports this principle, making their machines a trusted choice for industrial applications.

Conclusion: A Reliable Solution for Modern Manufacturing

The Stainless Steel Wire Mesh Weaving Machine is a testament to engineering excellence, offering unmatched precision, versatility, and durability. Whether you're producing wire mesh for construction, filtration, or automotive applications, this machine provides a reliable solution to meet your needs. With its advanced PLC control, wide weaving capabilities, and robust technical specifications, it is a valuable asset for any industrial operation. For more information, visit Anping Hongke Wire Mesh Machinery Factory.

References

National Institute of Standards and Technology (NIST). (2025). *Precision in Manufacturing*. Retrieved from https://www.nist.gov/

Pervious