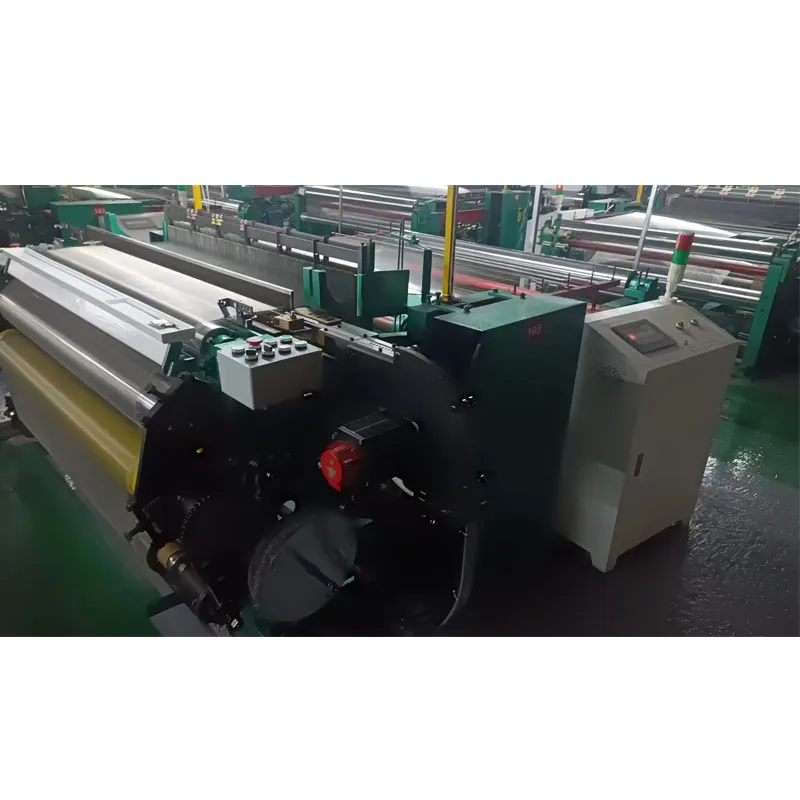

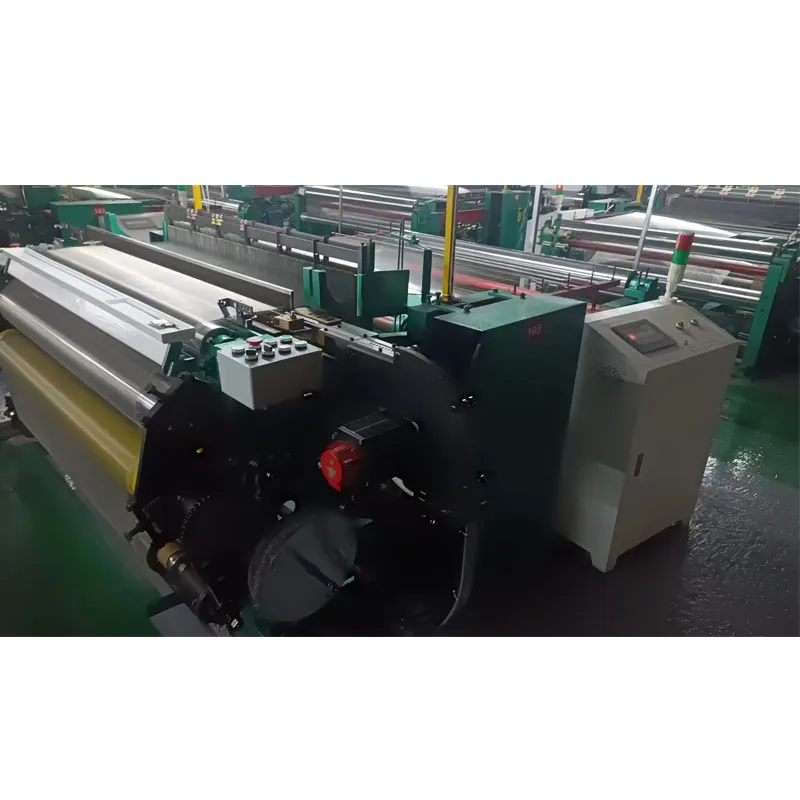

Stainless Steel Wire Mesh Weaving Machine - High-Efficiency Solutions for Industrial Applications

As a leading manufacturer in the wire mesh machinery industry, Anping Hongke Wire Mesh Machinery Factory specializes in developing high-performance stainless steel wire mesh weaving machines that cater to diverse industrial needs. Our machines combine advanced technology with robust engineering to deliver exceptional efficiency and precision in mesh production. Whether you're involved in construction, filtration, or industrial screening, our solutions ensure optimal results while reducing operational costs. Learn more about our Stainless Steel Wire Mesh Weaving Machine and how it can revolutionize your manufacturing process.

Product Overview: Stainless Steel Wire Mesh Weaving Machine

The Stainless Steel Wire Mesh Weaving Machine is designed to streamline the production of stainless steel wire mesh, a critical component in various industries. This machine utilizes automated weaving technology to produce high-quality mesh with consistent patterns and durability. Key features include:

- High-Speed Operation: Efficiently produces wire mesh at industrial-scale speeds.

- Precision Weaving: Ensures accurate mesh patterns for consistent quality.

- Durable Construction: Built with corrosion-resistant materials for long-term reliability.

- User-Friendly Controls: Intuitive interface for easy operation and maintenance.

Why Choose Our Stainless Steel Wire Mesh Weaving Machine?

Our machine stands out in the market due to its superior performance and innovative design. Here are the key advantages:

- Enhanced Productivity: Reduces manual labor and accelerates the weaving process, significantly increasing output.

- Cost-Effective: Minimizes material waste and energy consumption, lowering overall production costs.

- Customizable Options: Offers flexibility to adjust mesh specifications based on client requirements.

- Low Maintenance: Designed for minimal downtime, ensuring continuous operation.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | WH-800 (Standard) |

| Max Mesh Size | 1000mm x 1000mm |

| Wire Diameter Range | 0.2mm - 2.0mm |

| Speed | 10-30 meters/minute |

| Power Supply | 380V, 50Hz |

| Weight | 800kg |

Applications in Various Industries

The versatility of the Stainless Steel Wire Mesh Weaving Machine makes it suitable for multiple sectors, including:

- Construction: Used for reinforcing concrete and creating mesh for fencing.

- Filtration: Produces mesh for industrial filters and air purification systems.

- Industrial Screening: Ideal for separating materials in mining, agriculture, and food processing.

- Automotive: Manufacturing components like exhaust systems and air filters.

Addressing Industry Challenges

Traditional mesh production methods often face challenges such as inconsistent quality, high labor costs, and limited scalability. Our Stainless Steel Wire Mesh Weaving Machine tackles these issues by:

- Ensuring Consistency: Automated weaving eliminates human error, resulting in uniform mesh quality.

- Reducing Labor Costs: Minimizes the need for manual labor, lowering operational expenses.

- Scaling Production: Supports large-volume manufacturing without compromising on speed or quality.

About Anping Hongke Wire Mesh Machinery Factory

Established in 2008, Anping Hongke Wire Mesh Machinery Factory has become a trusted name in the wire mesh machinery industry. With over 15 years of experience, we specialize in designing and manufacturing high-quality weaving machines that meet international standards. Our commitment to innovation and customer satisfaction has earned us a global clientele, including major manufacturers in the construction and filtration sectors.

Our Technological Advancements

At Anping Hongke, we invest heavily in research and development to stay at the forefront of industrial machinery. Our Stainless Steel Wire Mesh Weaving Machine incorporates:

- Advanced Automation: Integrates smart control systems for seamless operation.

- Energy Efficiency: Optimizes power usage to reduce environmental impact.

- Modular Design: Allows for easy upgrades and adaptability to new production demands.

Proven Results and Customer Testimonials

Our machines have been successfully implemented in numerous industrial settings, delivering measurable benefits. For example, a leading filtration company in Germany reported a 40% increase in production efficiency after adopting our machine. Customer feedback highlights:

"The Stainless Steel Wire Mesh Weaving Machine from Anping Hongke has transformed our production line. The precision and reliability are unmatched." – John Smith, Production Manager at TechFilter GmbH

Usage Guide and Customization Options

To maximize the performance of your Stainless Steel Wire Mesh Weaving Machine, follow these steps:

- Installation: Ensure the machine is placed on a stable, level surface and connected to the power supply.

- Material Preparation: Select the appropriate stainless steel wire diameter and ensure it is properly fed into the machine.

- Configuration: Adjust the settings for mesh size, pattern, and speed according to your requirements.

- Operation: Initiate the weaving process and monitor the output for quality and consistency.

We also offer customization services to tailor the machine to your specific needs, including adjustments for different mesh sizes and materials.

Safety and Compliance

Our machines are designed with safety as a top priority. They comply with international standards such as ISO 9001 and CE certification. Features include:

- Emergency Stop Mechanism: Ensures immediate shutdown in case of malfunction.

- Protective Enclosures: Safeguards operators from moving parts during operation.

- Environmental Compliance: Manufactured using eco-friendly materials and processes.

Packaging and Delivery

We ensure safe and efficient delivery of our machines through:

- Durable Packaging: Machines are securely packed in reinforced wooden crates to prevent damage during transit.

- Global Shipping: Offers logistics solutions to clients worldwide, with options for sea, air, and land freight.

- Timely Delivery: Committed to meeting deadlines with reliable shipping partners.

Comprehensive Customer Support

At Anping Hongke, we provide end-to-end support to ensure your success:

- Technical Support: Our team offers 24/7 assistance for troubleshooting and maintenance.

- Training Programs: Provides on-site or remote training to help your staff operate the machine effectively.

- Warranty and Repairs: Includes a 12-month warranty and priority repair services for all machines.

Contact Us for More Information

Ready to elevate your production capabilities? Contact Anping Hongke Wire Mesh Machinery Factory today to learn more about our Stainless Steel Wire Mesh Weaving Machine. Our experts are available to answer your questions and provide personalized solutions. Visit our website or call us at +86-312-685-2255 for immediate assistance.

FAQs

1. What materials can the Stainless Steel Wire Mesh Weaving Machine handle?

The machine is specifically designed for stainless steel wires, but it can also accommodate other metals like carbon steel and aluminum with minor adjustments.

2. How long does it take to install the machine?

Installation typically takes 1-2 days, depending on the complexity of the setup. Our team can provide on-site installation support if required.

3. What is the maintenance schedule for the machine?

Regular maintenance is recommended every 500 hours of operation, including lubrication of moving parts and inspection of electrical components.

4. Can the machine be customized for specific mesh patterns?

Yes, we offer customization options to create unique mesh patterns tailored to your application requirements.

Conclusion

The Stainless Steel Wire Mesh Weaving Machine from Anping Hongke Wire Mesh Machinery Factory is a game-changer for industrial mesh production. With its advanced technology, durability, and cost-effectiveness, it empowers businesses to achieve higher productivity and quality. Discover how our solutions can transform your operations and contact us today to schedule a consultation.