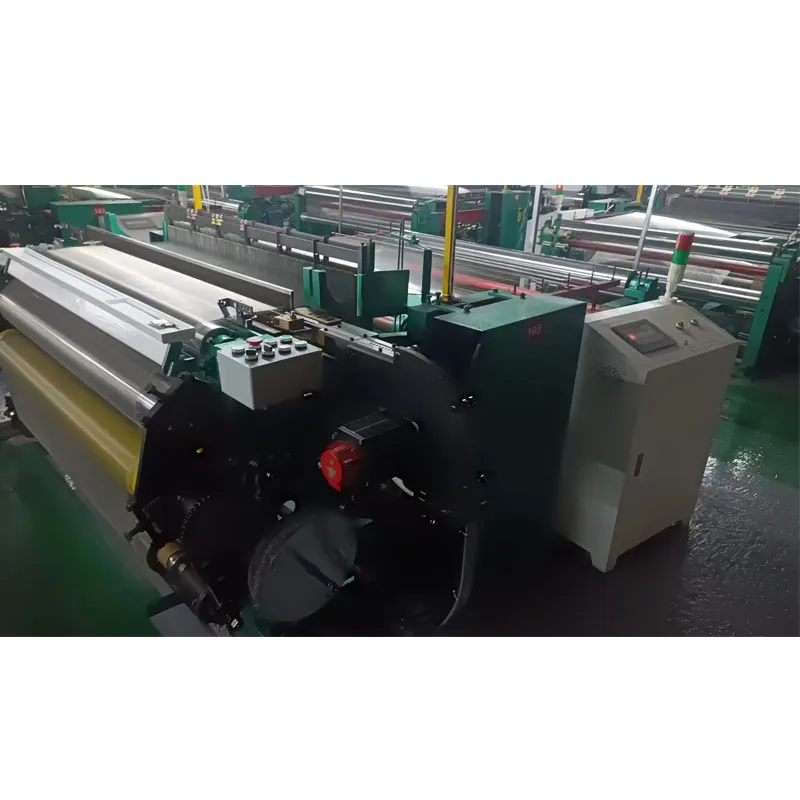

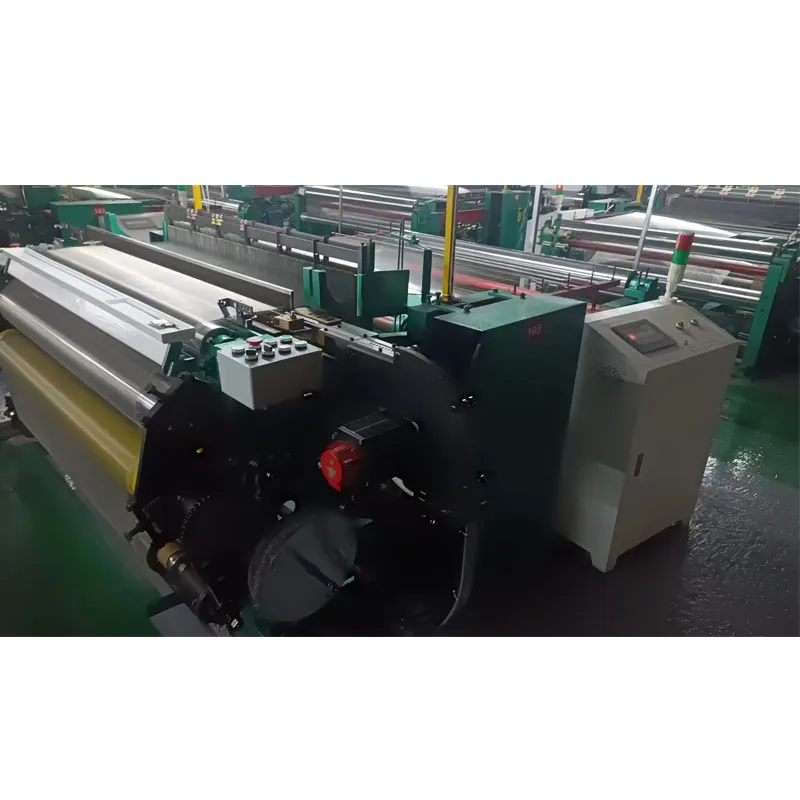

Stainless Steel Wire Mesh Weaving Machine: Precision, Versatility, and Innovation

The Stainless Steel Wire Mesh Weaving Machine represents a pinnacle of modern textile engineering, designed to produce high-quality wire mesh with exceptional precision and efficiency. This machine is engineered to meet the demands of industries requiring durable, corrosion-resistant mesh for applications ranging from industrial filtration to architectural design. With its advanced PLC control system, customizable weaving patterns, and robust technical specifications, this machine stands out as a reliable solution for manufacturers seeking to enhance productivity and product quality.

Product Overview

The Stainless Steel Wire Mesh Weaving Machine is a state-of-the-art device that combines mechanical precision with digital control to produce wire mesh with customizable patterns. Its design emphasizes flexibility, durability, and ease of operation, making it ideal for both small-scale and large-scale production. The machine is capable of weaving a wide range of materials, including stainless steel, iron, copper, and aluminum, ensuring versatility for diverse industrial needs.

Key Features

- PLC Control System: Enables precise adjustment of mesh patterns and parameters, ensuring consistent quality and adaptability to different requirements.

- Wide Weaving Width: Supports widths ranging from 1000 to 2000 mm, with reinforced structures for larger dimensions.

- Multiple Weaving Patterns: Capable of plain weaving, four-shafts twill, and special five-shafts weaving, offering flexibility for complex designs.

- High-Speed Operation: Achieves a beaming speed of approximately 25 meters per minute (82 feet), optimizing production efficiency.

Technical Specifications

The Stainless Steel Wire Mesh Weaving Machine is equipped with a comprehensive set of technical specifications that highlight its performance and adaptability. Below is a detailed table summarizing the key parameters:

| Parameter | Details |

|---|---|

| Weaving Width | 1000 to 2000 mm (with reinforcement for larger widths) |

| Wire Diameter | Up to 0.6 mm (refer to chart for precise ranges) |

| Wire Materials | Iron, stainless steel, spring steel, copper, brass, bronze, aluminum, plastic asbestos |

| Picking Speed | Adjustable via frequency control; electromagnetic motor drive (950 r.p.m.) with friction clutch and V-belts |

| Beaming Drive | Chain-driven from the main driving clutch |

| Beaming Speed | Approximately 25 m/min (82 ft) |

| Stopping Devices | 220 V AC (primary) and 24 V (secondary) for warp and weft |

| Weaving Reed Measurements | Overall height: 70 mm; reed slot: 7 mm and 10 mm with 1.1 mm thickness plate |

| Maximum Reed Length | Approximately weaving width + 60 mm |

| Heddle Measurements | Hole center distance: 173 mm or 200 mm; heddles nos. 2, 4, and 5 |

| Heddle Frame Plates | nos. 2, 4, and 5 |

Applications and Industry Use Cases

The Stainless Steel Wire Mesh Weaving Machine is designed to cater to a wide array of industries, including but not limited to:

- Industrial Filtration: Produces high-quality mesh for air and liquid filtration systems in chemical plants, food processing, and pharmaceuticals.

- Architectural Design: Offers durable and aesthetically pleasing mesh for building facades, partitions, and decorative elements.

- Construction and Safety: Creates mesh for scaffolding, safety nets, and protective barriers in construction sites.

- Automotive and Aerospace: Provides lightweight, corrosion-resistant components for vehicle and aircraft manufacturing.

- Agri-Food Sector: Ensures hygienic and durable mesh for sorting, packaging, and storage solutions.

Company Background: Anping Hongke Wire Mesh Machinery Factory

The Anping Hongke Wire Mesh Machinery Factory is a leading manufacturer of wire mesh machinery, specializing in the production of high-performance weaving machines. Located in Anping County, Hebei Province, China, the company has established itself as a trusted name in the industry, known for its innovation, quality, and customer-centric approach. With over a decade of experience, Anping Hongke has consistently delivered solutions that meet the evolving needs of global manufacturers.

As a pioneer in the field, Anping Hongke adheres to rigorous quality control standards, ensuring that every machine meets international benchmarks for reliability and efficiency. The company's commitment to research and development has enabled it to introduce cutting-edge technologies, such as the PLC control system featured in the Stainless Steel Wire Mesh Weaving Machine, which enhances operational precision and flexibility.

Why Choose the Stainless Steel Wire Mesh Weaving Machine?

The Stainless Steel Wire Mesh Weaving Machine offers several advantages that make it a preferred choice for manufacturers:

- Customization: Supports a wide range of weaving patterns and materials, allowing for tailored solutions to specific industry needs.

- Efficiency: High-speed operation and automated controls reduce production time and labor costs.

- Durability: Constructed with high-quality materials and reinforced structures to withstand demanding environments.

- Scalability: Suitable for both small-scale and large-scale production, making it adaptable to varying business requirements.

- Compliance: Meets international standards for safety, performance, and environmental sustainability.

Industry Standards and Compliance

The Stainless Steel Wire Mesh Weaving Machine is designed to align with global manufacturing standards, ensuring safety, reliability, and performance. According to the National Institute of Standards and Technology (NIST), "Precision in manufacturing processes is critical for ensuring product consistency and quality. Advanced machinery like the stainless steel wire mesh weaving machine plays a vital role in achieving these standards through automated controls and robust design" (NIST).

NIST's research on industrial automation highlights the importance of integrating digital control systems, such as PLCs, to enhance operational efficiency and reduce human error. The Stainless Steel Wire Mesh Weaving Machine exemplifies this principle, offering precise adjustments and real-time monitoring to optimize production outcomes.

Conclusion

The Stainless Steel Wire Mesh Weaving Machine is a testament to the advancements in textile engineering and industrial automation. With its advanced PLC control system, versatile weaving capabilities, and adherence to international standards, this machine is an essential tool for manufacturers seeking to produce high-quality wire mesh efficiently. By partnering with Anping Hongke Wire Mesh Machinery Factory, businesses can leverage cutting-edge technology to meet the demands of modern industries.

References

National Institute of Standards and Technology (NIST)

Pervious