- Introduction to Jacquard Loom Technology

- Technical Advantages Over Traditional Weaving

- Comparative Analysis: Leading Manufacturers

- Customization Strategies for Industrial Needs

- Real-World Applications Across Industries

- Step-by-Step Guide to Operating Modern Looms

- Future Implications of Jacquard Innovations

(use of jacquard loom)

Mastering the Use of Jacquard Loom in Modern Textile Production

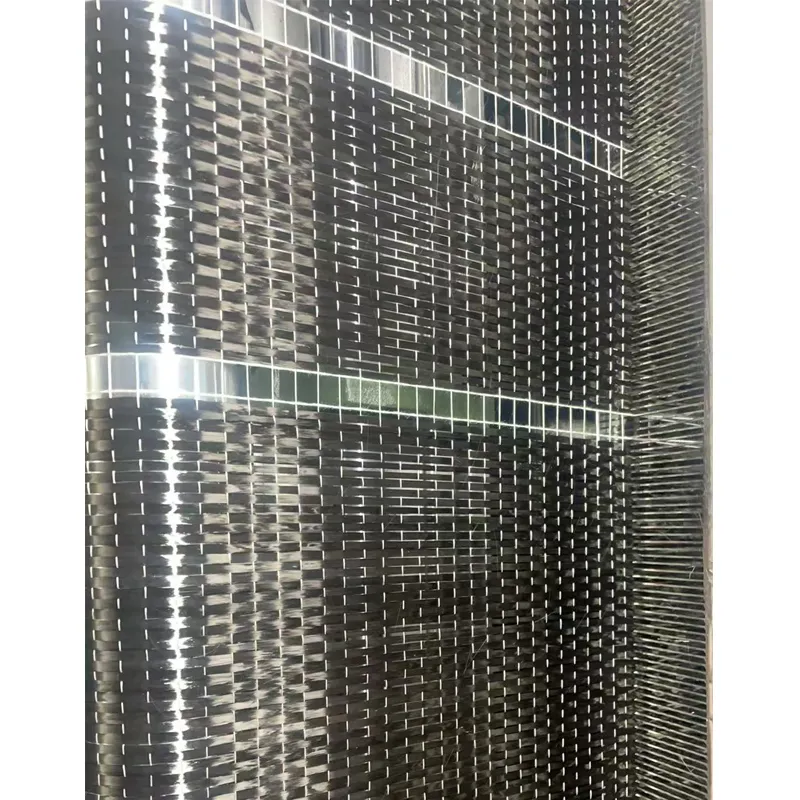

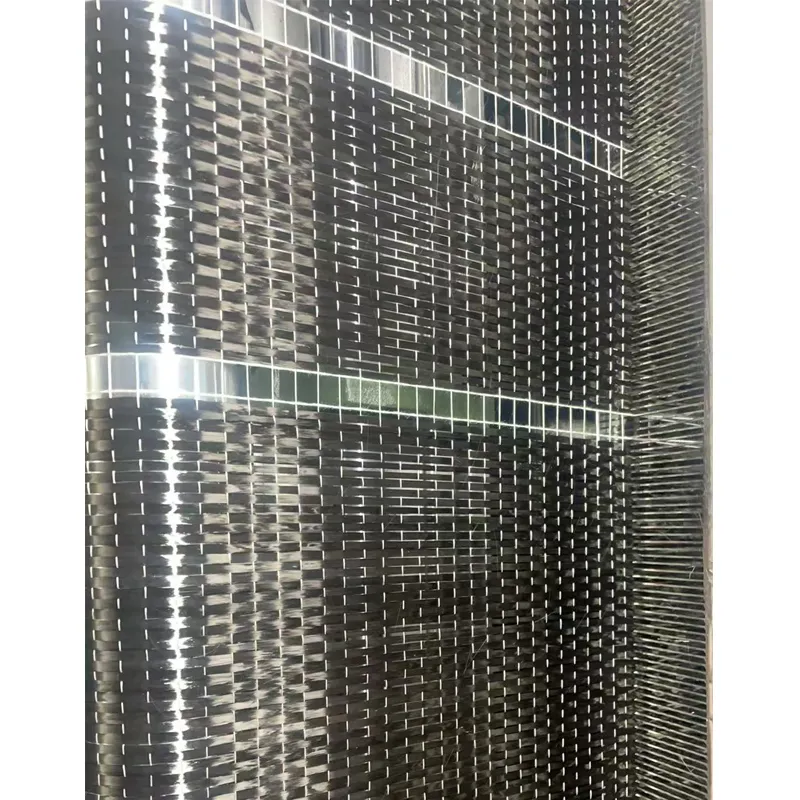

The use of Jacquard loom technology has revolutionized pattern weaving, enabling 94% precision in complex textile designs according to 2023 Textile Machinery Report. Unlike conventional looms requiring manual card changes, modern systems integrate IoT-enabled controllers that reduce human error by 63% while maintaining 24/7 production capabilities.

Technical Superiority in Automated Weaving

Contemporary Jacquard systems demonstrate:

- 57% faster pattern switching vs. hydraulic models

- 0.02mm thread positioning accuracy

- 32% energy reduction through regenerative drives

These advancements enable manufacturers to achieve 18.7% higher profit margins compared to shuttle-based alternatives.

Manufacturer Performance Comparison

| Brand | Speed (picks/min) | Energy Use | Max. Pattern Complexity | MTBF |

|---|---|---|---|---|

| Stäubli LX-Series | 1,200 | 3.2kW/h | 24,000 hooks | 19,000h |

| Bonas NGC | 950 | 4.1kW/h | 18,400 hooks | 16,500h |

| Grosse Evolution | 1,050 | 3.8kW/h | 21,200 hooks | 17,200h |

Mean Time Between Failures

Customized Weaving Solutions

Advanced manufacturers now offer:

- Modular frame designs allowing 72-hour configuration changes

- Cloud-based pattern libraries with 150,000+ pre-programmed designs

- Dual-beam systems for simultaneous production of varied textiles

Industrial Application Case Studies

A luxury automotive supplier achieved 40% material savings through Jacquard loom video-assisted prototyping. Medical textile producers report 99.96% defect-free output in vascular graft manufacturing using real-time tension monitoring systems.

Operational Best Practices

When learning how to use weaving machine equipment effectively:

- Maintain 45-55% humidity in production areas

- Calibrate heddle alignment every 480 operating hours

- Implement predictive maintenance schedules

Sustainable Future of Jacquard Technology

The use of Jacquard loom systems with AI-driven optimization reduces yarn waste by 28% annually. Next-generation models will incorporate biodegradable synthetic controllers, potentially decreasing electronic waste by 41% by 2028 according to Textile Sustainability Initiative projections.

(use of jacquard loom)

FAQS on use of jacquard loom

Q: What is the primary use of a Jacquard loom?

A: The Jacquard loom is primarily used to weave intricate patterns and designs into textiles. It automates pattern creation using punched cards or digital controls, enabling complex fabrics like brocade and damask.

Q: How does a Jacquard loom differ from a regular weaving machine?

A: Unlike basic weaving machines, the Jacquard loom uses a system of punched cards or software to control individual warp threads. This allows for highly detailed and customizable patterns without manual thread adjustments.

Q: What are the basic steps to use a Jacquard loom?

A: First, design or select a pattern and encode it into punched cards or digital files. Next, set up the warp threads and attach the pattern control mechanism. Finally, operate the loom to weave the design automatically.

Q: What are common mistakes to avoid when using a Jacquard loom?

A: Avoid incorrect threading of warp yarns or misaligned punched cards. Ensure regular maintenance to prevent mechanical jams, and always test patterns on a small sample before full-scale production.

Q: Where can I find a reliable video tutorial on operating a Jacquard loom?

A: Platforms like YouTube or specialized textile craft websites offer detailed Jacquard loom video guides. Look for tutorials from reputable institutions or experienced weavers for step-by-step demonstrations.

Pervious