- Introduction to Wire Mesh Machine Price and Market Overview

- Technical Advantages and Innovations in Wire Mesh Making Machines

- Detailed Comparison of Top Manufacturers

- Customization Options and Solutions for Different Industries

- Application Scenarios and Case Studies

- Maintenance, Operation Costs, and ROI Considerations

- Conclusion: How to Assess Wire Mesh Machine Price and Value

(wire mesh machine price)

Introduction to Wire Mesh Machine Price and Market Overview

Wire mesh machine price has come into sharp focus for global buyers, as automation and infrastructure development drive demand for mesh-based materials. According to recent industrial analyses, the worldwide market for wire mesh manufacturing machines was valued at approximately $2.4 billion in 2023, with projections estimating a CAGR of 5.6% through 2029. Price ranges are broad, primarily influenced by automation level, production output, mesh specifications, and manufacturer brand. Entry-level automated wire mesh making machines start from $8,000, while advanced, high-speed models can exceed $125,000. This overview aims to explore cost determinants, technical progress, and market dynamics shaping the industry, providing comprehensive guidance for purchasers and manufacturers alike.

Technical Advantages and Innovations in Wire Mesh Making Machines

The wire mesh making machine segment has experienced rapid evolution in the past decade. Modern machines leverage servo-driven precision, programmable logic controllers, and real-time monitoring, resulting in faster output rates and reduced wastage. For instance, the latest CNC wire mesh welding machines deliver up to 180 strokes per minute while ensuring dimensional tolerances within ±0.2mm—key for high-demand sectors like construction and automotive.

Another notable advancement is adaptive mesh size switching, enabling transitions between different mesh sizes and wire gauges within minutes. This flexibility significantly boosts productivity. Additionally, energy consumption has been optimized; certain models consume less than 13kWh per 1000m of mesh produced—up to 25% less than machines of previous generations. Such enhancements not only elevate the competitive landscape but also directly impact operational cost efficiency and overall equipment effectiveness (OEE).

Detailed Comparison of Top Manufacturers

Choosing the right wire mesh manufacturing machine requires careful comparison of key suppliers. Established manufacturers differ in their offerings regarding technology, warranty, after-sales support, and base price. The table below summarizes the benchmarking of top global producers as of 2024:

| Manufacturer | Country | Model | Production Speed (m/min) | Mesh Size Range (mm) | Machine Price (USD) | Warranty (years) | Automation Features |

|---|---|---|---|---|---|---|---|

| Schlatter | Switzerland | MIG 2800 | 45 | 25–200 | 98,000+ | 2 | Full CNC, Remote Diagnostics |

| Jiaoyang | China | JL-2500 | 38 | 12.5–100 | 61,000+ | 1 | PLC, Servo Motors |

| EVG | Austria | GRA 800 | 52 | 25–100 | 125,000+ | 3 | Full CNC, MES Integration |

| Blue Steel | India | BWM-4500 | 30 | 50–200 | 39,500+ | 1 | Partial Automation |

| Progress Maschinen & Automation | Italy | MSR-3000 | 40 | 15–150 | 88,000+ | 2 | Auto-feeder, Data Logging |

Customization Options and Solutions for Different Industries

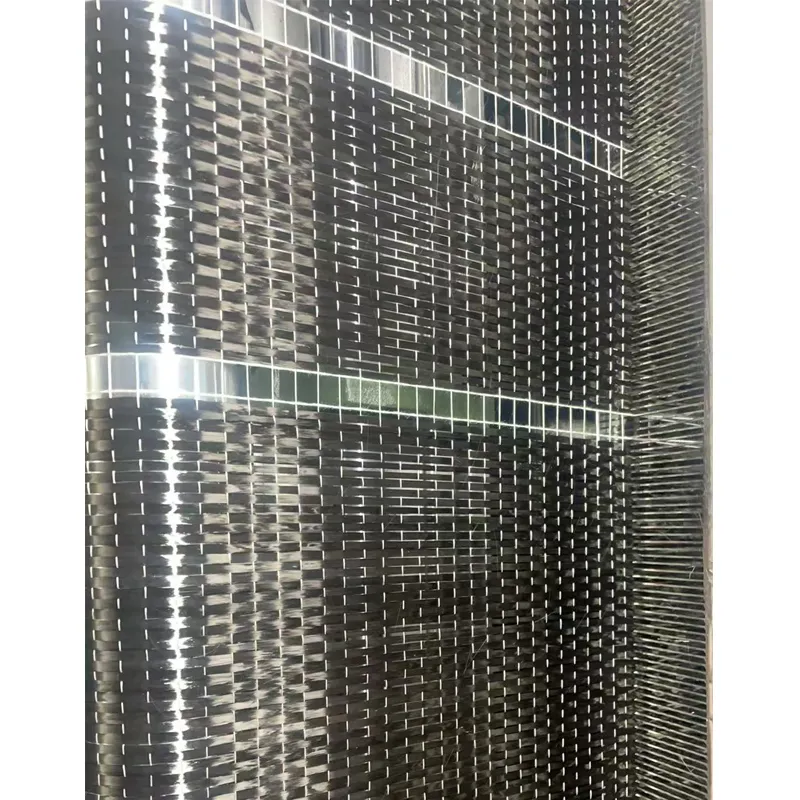

The diversity of applications demands highly customizable wire mesh making machines. Customization spans mesh aperture, wire diameter, speed-to-output balancing, feedstock type, and integration with downstream finishing processes (such as galvanizing or coating). For instance, architectural mesh producers often require intricate patterns and varying mesh sizes within a single roll, necessitating programmable and flexible weaving or welding capabilities.

Manufacturers also offer tailor-made wire mesh manufacturing machines for niche applications, including filtering mesh for chemical plants, high-tensile fencing for agriculture, and micro-mesh for electronics. Some models feature automatic material loaders, offcuts collection, and inline QA inspection to align with lean manufacturing setups. Moreover, integration with Enterprise Resource Planning (ERP) systems is gaining importance for just-in-time production, minimizing inventory and maximizing throughput.

Application Scenarios and Case Studies

Wire mesh manufacturing machines are integral in delivering tailored solutions across diverse sectors. In the construction industry, the World Steel Association reports that over 210 million tons of welded wire mesh were utilized globally in 2023 for reinforced concrete, highways, and airport runways. Automotive plants employ custom welded mesh for battery trays and component frameworks, enhancing durability and safety.

A notable case involved a Latin American infrastructure firm that adopted a fully automated EVG GRA 800 machine. The upgrade resulted in 34% higher throughput, a 22% reduction in energy usage, and ROI achieved within 18 months. Similarly, an Asian electronics manufacturer invested in a custom micro-mesh making machine to produce shielded enclosures for circuit boards; precision within ±0.1mm was necessary. This minimized rejection rates by 17% and unlocked new business for high-value sectors.

These scenarios underscore how advanced equipment maximizes productivity, reduces error, and supports diverse, growth-oriented operations.

Maintenance, Operation Costs, and ROI Considerations

Beyond the initial wire mesh machine price

, buyers must account for ongoing costs—consumables, maintenance, operator training, and energy consumption are pivotal. On average, annual maintenance accounts for 2-3% of the machine’s CAPEX, but predictive maintenance technologies are driving this figure down. Real-time monitoring helps detect anomalies preemptively, reducing unscheduled downtime by up to 30%. Operator skill requirements also vary; advanced models can lower manual intervention, though periodic calibration remains crucial.

Energy costs fluctuate by region, but improved drives and optimized welding protocols have led to 18–28% savings in electricity over five years. When calculating ROI, buyers should estimate annual output, labor, and potential savings from minimized material wastage. Many users report payback periods of 16–28 months, especially when switching from manual or semi-automatic systems to fully automated lines. Factoring in resale value is also relevant, as top-brand mesh machines tend to retain 50–65% of initial value after three years given appropriate maintenance.

Conclusion: How to Assess Wire Mesh Machine Price and Value

Assessing the real value of wire mesh machine price for modern manufacturing is multifaceted. Buyers are encouraged to evaluate not only upfront investment but also long-term cost savings, flexibility, technical innovation, and service support. The right choice ensures optimal production, higher product quality, and sustained competitiveness in a dynamic marketplace. As technological advancements continue, carefully aligning machine capacities with operational goals will become even more crucial, solidifying ROI and driving industry leadership.

(wire mesh machine price)

FAQS on wire mesh machine price

Q: What factors affect the wire mesh machine price?

A: The price of a wire mesh machine depends on its automation level, production capacity, and brand. Additional features like customization and support services may also impact the cost. It's best to compare models before making a decision.Q: How much does a standard wire mesh making machine cost?

A: A standard wire mesh making machine typically costs between $5,000 and $30,000. The price varies based on specifications and manufacturer. Always request a detailed quote for accurate pricing.Q: Are there differences in price between wire mesh manufacturing machine types?

A: Yes, prices differ based on the type, such as welded or woven mesh machines. Higher automation and advanced technology generally increase the price. Production requirements will guide your best choice.Q: Do wire mesh machines come with after-sales support in the price?

A: Many wire mesh machine prices include basic after-sales support and a warranty. Some manufacturers offer extended service for an additional fee. Always clarify support terms before buying.Q: Can I get a wire mesh making machine at a lower price for bulk orders?

A: Yes, manufacturers often provide discounts for bulk orders of wire mesh manufacturing machines. Negotiating directly with suppliers can help lower the overall unit price. Inquire about bulk pricing options when requesting a quote.

Pervious