Carbon Fiber Weaving Machines: Engineering the Future of Advanced Composites

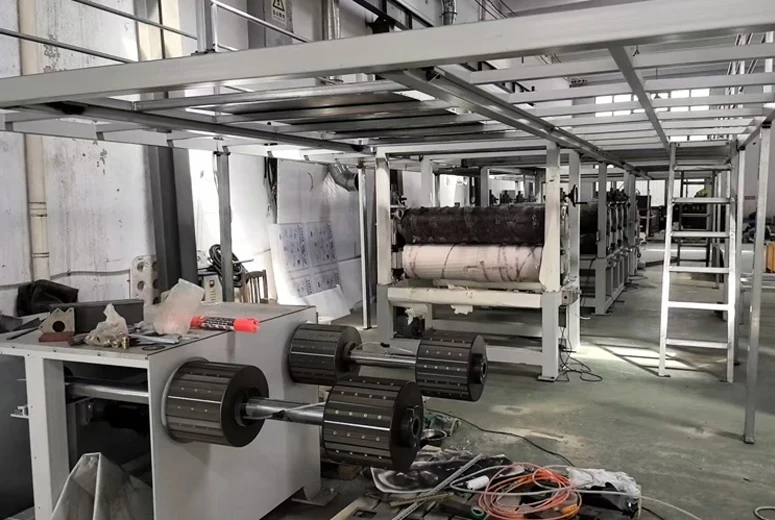

Anping Hongke Wire Mesh Machinery Factory has been at the forefront of textile machinery innovation, with our equipment operating in over a dozen countries worldwide. While we originally specialized in fiberglass machinery, our technological advancements have led us to develop state-of-the-art Carbon Fiber Weaving Machines that meet the exacting demands of modern composite manufacturing. These sophisticated machines represent the cutting edge of industrial textile production, enabling the creation of high-performance carbon fiber fabrics for aerospace, automotive, and defense applications.

Understanding Carbon Fiber Weaving Machines

The Carbon Fiber Weaving Machine is a precision instrument designed to handle the unique challenges posed by carbon fiber filaments. Unlike traditional textile weaving machines, these specialized units must accommodate carbon fiber's exceptional strength combined with its relative brittleness. Our machines feature advanced tension control systems that maintain the delicate balance between keeping fibers taut enough for proper weaving while preventing breakage that could compromise fabric integrity.

Modern carbon fiber weaving technology has evolved to produce complex weave patterns including plain, twill, and satin weaves, each offering distinct mechanical properties for different applications. The machines achieve this through computerized pattern control systems that precisely coordinate the movement of harnesses, reeds, and weft insertion mechanisms. This level of control allows manufacturers to produce carbon fiber fabrics with specific strength orientations tailored to their end-use requirements.

Carbon Fiber Weaving Machine: Key Technological Features of Modern Machines

Today's Carbon Fiber Weaving Machines incorporate several groundbreaking features that set them apart from conventional weaving equipment. Advanced ceramic guide systems minimize fiber abrasion during the weaving process, preserving the structural integrity of the carbon filaments. Specialized weft insertion mechanisms, including rapier and air-jet systems, have been adapted to handle carbon fiber's unique properties without causing damage or fraying.

Perhaps most importantly, our machines feature real-time monitoring systems that track every aspect of the weaving process. These systems can detect minute tension variations, identify potential thread breaks before they occur, and automatically adjust machine parameters to maintain optimal weaving conditions. This level of automation ensures consistent fabric quality while maximizing production efficiency.

Applications Transforming Industries

The fabrics produced by Carbon Fiber Weaving Machines are revolutionizing multiple industries. In aerospace, these machines create the lightweight yet incredibly strong fabrics used in aircraft fuselages and wing components. The automotive sector utilizes carbon fiber weaves for high-performance vehicle parts that reduce weight while improving safety and fuel efficiency. Renewable energy applications include wind turbine blades that benefit from carbon fiber's exceptional strength-to-weight ratio.

Emerging applications continue to expand the horizons of carbon fiber weaving technology. Medical prosthetics, high-end sporting equipment, and even next-generation architectural elements increasingly rely on the precision fabrics produced by these advanced machines. The ability to customize weave patterns and fiber orientations allows engineers to create composite materials with precisely tailored mechanical properties for each specific application.

Technical Considerations in Carbon Fiber Weaving

Operating a Carbon Fiber Weaving Machine requires careful attention to numerous technical factors. Humidity and temperature control are critical, as carbon fiber's weaving characteristics can change with environmental conditions. The machines must maintain perfect synchronization between warp let-off and fabric take-up mechanisms to prevent tension variations that could affect fabric quality.

Fiber sizing - the protective coating applied to carbon fibers - plays a crucial role in weaving performance. Our machines are designed to work with various sizing formulations while minimizing sizing damage during the weaving process. Additionally, the machines incorporate specialized cleaning systems that remove loose fibers and debris, maintaining a clean weaving environment that prevents fabric defects.