The Essential Role of Fiberglass Mesh Weaving Machines in Modern Industry

Since its founding in 2008, Anping Hongke Wire Mesh Machinery Factory has been a trusted manufacturer of high-performance wire mesh production equipment. Our machines are exported worldwide, serving industries in Egypt, Turkey, India, Russia, and beyond. Among our key products, the Fiberglass Mesh Weaving Machine plays a crucial role in manufacturing durable and versatile fiberglass mesh, which is widely used in construction, filtration, and industrial applications.

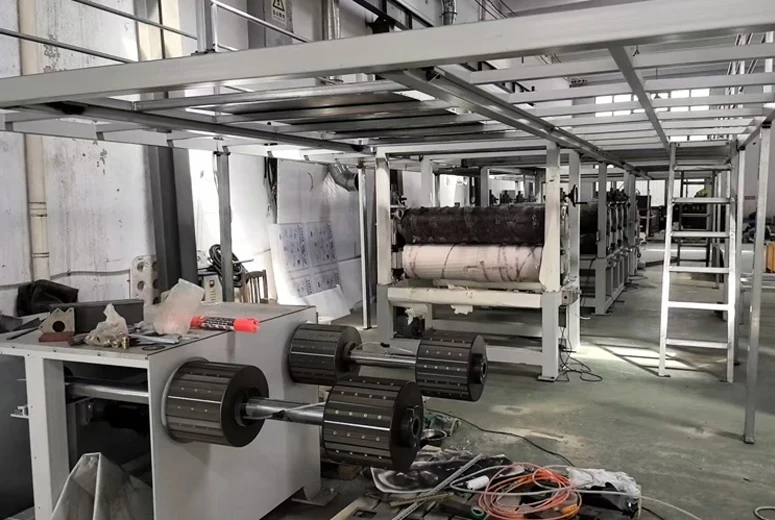

Understanding the Fiberglass Mesh Weaving Machine

A Fiberglass Mesh Weaving Machine is a specialized piece of equipment designed to interlace fiberglass yarns into a strong, uniform mesh structure. Unlike traditional textile weaving, this process requires precision handling of fiberglass filaments, which are inherently brittle and require careful tension control. The machine ensures consistent weaving patterns, resulting in a stable and high-strength mesh suitable for demanding applications.

Fiberglass mesh is known for its lightweight yet robust properties, making it ideal for reinforcement, insulation, and protective applications. The weaving process must maintain tight control over yarn alignment and density to ensure the final product meets industry standards.

How the Fiberglass Mesh Weaving Machine Works

The weaving process begins with fiberglass yarns fed from creels into the machine. These yarns are carefully guided through tensioning devices to prevent breakage and ensure uniformity. The Fiberglass Mesh Weaving Machine then uses a series of heddles and reeds to separate warp (lengthwise) and weft (crosswise) yarns, interlacing them in a precise pattern.

Advanced models feature electronic controls to adjust weaving speed, tension, and mesh density, allowing manufacturers to produce different mesh specifications efficiently. The resulting fiberglass mesh is then treated with coatings (such as alkali-resistant or fireproof finishes) to enhance its performance in specific environments.

Key Applications of Woven Fiberglass Mesh

Fiberglass mesh produced by these machines is widely used in:

Construction Reinforcement – As a key component in stucco, plaster, and concrete reinforcement, fiberglass mesh prevents cracking and improves structural integrity.

Industrial Filtration – The mesh’s fine weave and chemical resistance make it suitable for air and liquid filtration systems.

Fireproofing and Insulation – Coated fiberglass mesh is used in fire-resistant barriers and thermal insulation materials.

Composite Materials – It serves as a reinforcing layer in fiberglass-reinforced plastics (FRP) for automotive and aerospace applications.

Why Choose Anping Hongke’s Fiberglass Mesh Weaving Machine?

With years of expertise in wire mesh machinery, we have engineered our Fiberglass Mesh Weaving Machine for reliability, efficiency, and ease of operation. Key advantages include:

High-Speed Precision Weaving – Ensures consistent mesh quality with minimal yarn breakage.

Customizable Weaving Patterns – Supports different mesh densities and weave styles to meet various industry needs.

Durable Construction – Built with high-quality components to withstand continuous industrial use.

Energy Efficiency – Designed to optimize power consumption while maintaining high productivity.

At Anping Hongke Wire Mesh Machinery Factory, we remain committed to advancing fiberglass production technology. Whether you need a standard weaving machine or a customized solution, our expertise ensures you receive equipment that meets global quality standards.

For more information on our fiberglass machinery, including window screen machines, fireproof cloth production lines, and woven roving machines, contact us today. Let us help you enhance your manufacturing capabilities with cutting-edge fiberglass weaving technology.