Anping Hongke Wire Mesh Machinery Factory, established in 2008, has emerged as a leading professional manufacturer of wire mesh and composite material machinery. With a global export footprint spanning Egypt, Turkey, India, Russia, Saudi Arabia, Romania, Kazakhstan, and beyond, the factory specializes in delivering high - performance carbon fiber machine systems. Committed to technological innovation, the company combines decades of expertise with cutting - edge design to produce equipment for carbon fiber processing, including prepreg machines and carbon fiber weaving looms. Engineered for precision and reliability, Anping Hongke’s machinery caters to the growing demands of aerospace, automotive, and industrial composite applications.

Carbon Fiber Machine: Comprehensive Solutions for Composite Processing

Anping Hongke’s carbon fiber machine portfolio encompasses a range of specialized equipment designed to transform raw carbon fiber materials into high - performance composites:

- Extrusion Systems:

Convert carbon fiber filaments into uniform profiles with precise diameter control (5–12 μm), suitable for aerospace - grade components. - Twisting Machines:

Intertwine carbon fiber yarns to enhance tensile strength, supporting up to 6,000 denier yarns for structural applications. - Drying and Conditioning Units:

Remove moisture from carbon fibers, ensuring dimensional stability during composite manufacturing.

Machine Specifications:

|

Equipment Type |

Processing Speed |

Power Consumption |

Material Compatibility |

|

Carbon Fiber Extruder |

80–200 m/min |

40–80 kW |

PAN - based, pitch - based CF |

|

Twisting Machine |

400–1,000 rpm |

15–30 kW |

Multifilament carbon yarns |

Prepreg Machine: Precision in Resin Impregnation

The factory’s prepreg machines are engineered to impregnate carbon fibers with resin systems, creating pre - saturated materials for composite layup:

- Resin Impregnation Technology:

- Hot - Melt Impregnation: Applies thermoset resins at controlled temperatures (120–200°C) for uniform distribution.

- Solvent - Based Impregnation: Suitable for complex resin systems, with solvent recovery rates exceeding 95%.

- Key Features:

- Tension Control: Maintains ±1% tension during impregnation to prevent fiber damage.

- Thickness Accuracy: Achieves resin - to - fiber ratios within ±2% tolerance.

- Application Scenarios:

- Aerospace: Wing skins and fuselage components.

- Automotive: Lightweight body panels and drivetrain parts.

Prepreg Machine Models:

|

Model |

Impregnation Method |

Width Capacity |

Throughput |

|

HKP - 1200 |

Hot - melt |

1,200 mm |

50–100 kg/h |

|

HKP - 1800 |

Solvent - based |

1,800 mm |

80–150 kg/h |

Prepreg Machine Market: Trends and Industry Demand

The prepreg machine market is driven by growing composite applications in high - tech industries, with Anping Hongke at the forefront of innovation:

- Market Growth Drivers:

- Aerospace: Rising demand for fuel - efficient aircraft components.

- Renewable Energy: Carbon fiber composites in wind turbine blades.

- Anping Hongke’s Market Position:

- Export Portfolio: 60% of prepreg machines sold to Europe and North America.

- Custom Solutions: 40% of orders are tailored to client specifications.

- Market Comparison Table:

|

Region |

Growth Rate (2023–2028) |

Key Applications |

|

Asia - Pacific |

8.5% |

Automotive and construction |

|

North America |

7.2% |

Aerospace and defense |

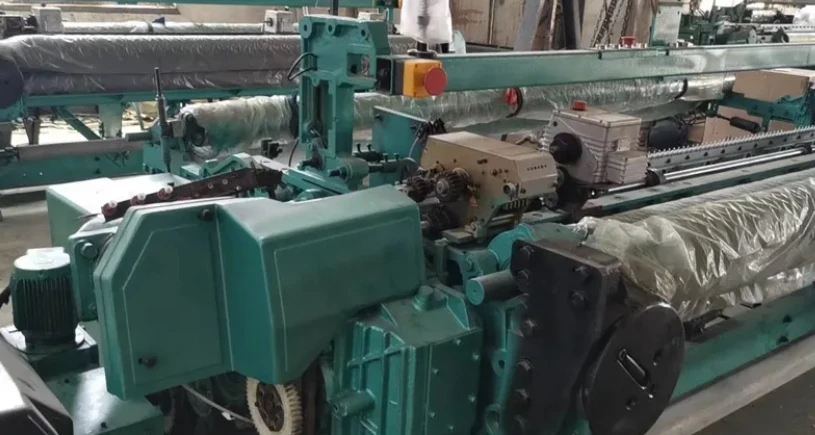

Carbon Fiber Weaving Loom: High - Performance Fabric Production

Anping Hongke’s carbon fiber weaving looms are designed for producing complex carbon fiber fabrics with precise weave patterns:

- Weaving Technology:

- Rapier Looms: Ideal for high - density fabrics (up to 300 threads/inch) for ballistic protection.

- Shuttleless Looms: Offer 30% faster weaving speeds for mass - production of automotive fabrics.

- Weaving Parameters:

- Tensile Strength: Fabrics achieve 3,000–5,000 MPa for structural applications.

- Weave Types: Plain, twill, and harness weaves for diverse composite needs.

- Application Cases:

|

Industry |

Fabric Type |

Performance Requirement |

|

Defense |

Multiaxial fabric |

Ballistic resistance |

|

Sports Equipment |

Lightweight twill |

Impact absorption |

FAQs About Carbon Fiber Machinery

What distinguishes your carbon fiber machine handling capabilities?

Our carbon fiber machine, which is a marvel of modern engineering, incorporates advanced electrostatic control mechanisms and ceramic guides. These innovative features work in tandem to ensure that the filaments are protected from any potential damage during the high-speed processing operations.

How does your prepreg machine ensure resin consistency?

Our prepreg machine systems are equipped with precision metering pumps and temperature-controlled rollers, which work in tandem to ensure a consistent and uniform distribution of resin throughout the process.

What trends drive the prepreg machine market evolution?

Increasing demand for aerospace-grade composites and renewable energy applications shapes prepreg machine market development.

Can your carbon fiber weaving loom handle hybrid fabrics?

Yes, our carbon fiber weaving loom accommodates hybrid weaving with glass/aramid fibers through adjustable tension zones.

What maintenance do your prepreg machine require?

All systems feature self-lubricating components requiring only periodic sensor calibration and cleaning.

Partner with Anping Hongke for Advanced Composite Solutions

Anping Hongke Wire Mesh Machinery Factory delivers cutting - edge carbon fiber machine and prepreg machine solutions that drive innovation in composite manufacturing. With a focus on precision, reliability, and customer collaboration, our carbon fiber weaving looms and prepreg systems empower industries to create next - generation composite products. Contact us today to explore machinery options, request technical specifications, or schedule a consultation—let’s shape the future of composite materials together.