The Evolution of Carbon Fiber Manufacturing: Industry Trends and Technological Advancements

The global demand for high-performance materials continues to drive innovation in manufacturing, with carbon fiber standing at the forefront. Its unparalleled strength-to-weight ratio and exceptional stiffness make it indispensable across diverse sectors, including aerospace, automotive, sports equipment, and civil engineering. The efficiency and precision of the machinery used in its production are paramount, directly impacting the quality and cost-effectiveness of the final composite products. Recent industry trends highlight a significant shift towards automated, high-speed, and versatile weaving solutions capable of handling intricate patterns and varying fiber types. This evolution is crucial for meeting the escalating production requirements and design complexities that characterize modern advanced materials applications. Companies are increasingly investing in next-generation weaving technology to gain a competitive edge.

Key advancements are centered around improving weft insertion rates, reducing yarn breakage, and enhancing control over fabric density and uniformity. Furthermore, the integration of smart technologies, such as IoT sensors and AI-driven predictive maintenance, is transforming traditional weaving operations into highly efficient and data-driven processes. This allows for real-time monitoring of machine performance and immediate identification of potential issues, minimizing downtime and optimizing resource utilization. The focus on sustainability also pushes for more energy-efficient machines with reduced material waste. As a result, the capabilities of a carbon fiber machine, particularly those designed for complex mesh structures, are becoming increasingly sophisticated to meet the stringent demands of advanced composite manufacturing.

Understanding the Core: Carbon Fiber Weaving Machine Technology and Parameters

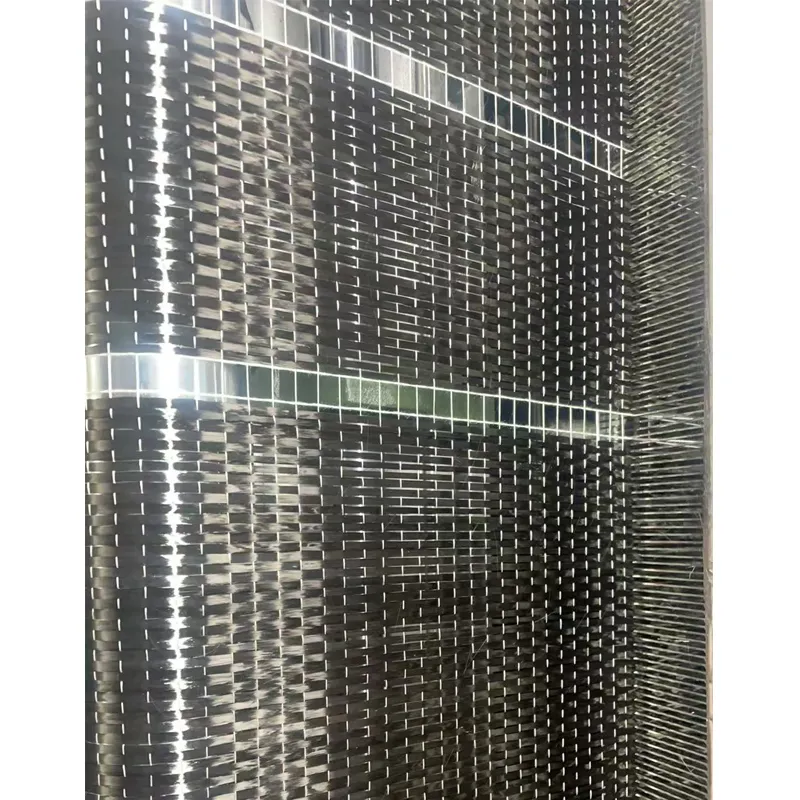

At the heart of high-quality carbon fiber composite production lies the precision of the weaving equipment. A leading example is the Carbon Fiber Mesh Rapier Loom, engineered for the intricate task of interlacing carbon filaments into precise mesh structures. The technical parameters of such a machine are critical to its performance and the quality of the output. These parameters include the nominal weaving width, which dictates the maximum fabric width the loom can produce, ranging typically from 1500mm to 3600mm for industrial applications. The weft insertion rate, measured in picks per minute (PPM), is another key indicator of productivity, with advanced looms achieving upwards of 400-600 PPM.

Furthermore, the type of shedding motion (e.g., dobby or jacquard), the number of heald frames, and the maximum weft density are vital for fabric design versatility and tightness. The manufacturing process of these looms themselves involves high-precision engineering. Components are typically forged for strength, then meticulously machined using advanced CNC (Computer Numerical Control) processes to achieve tight tolerances, often down to micrometers. This precision ensures smooth operation, minimal vibration, and extended machine lifespan. Inspection standards, such as ISO 9001 for quality management and ANSI standards for mechanical components, are strictly adhered to throughout the manufacturing process, guaranteeing reliability and performance consistency. The expected service life of such a robust carbon fiber machine can exceed 20 years with proper maintenance, ensuring a significant return on investment for manufacturers.

Application Scenarios and Technical Advantages: Powering Diverse Industries

The versatility of a Carbon Fiber Mesh Rapier Loom extends its application across a wide array of industries that demand lightweight yet incredibly strong materials. In the aerospace sector, it's used to produce primary and secondary structural components for aircraft, where weight reduction directly translates to fuel efficiency and increased payload capacity. The automotive industry utilizes carbon fiber for body panels, chassis components, and performance parts, enhancing vehicle dynamics and safety. Beyond these, the petrochemical industry benefits from corrosion-resistant composite pipes and tanks, while the metallurgy sector employs carbon fiber composites for high-temperature applications due to their excellent thermal stability. In civil engineering and construction, carbon fiber mesh reinforces concrete structures, offering superior crack resistance and extended longevity.

One of the primary technical advantages of using a specialized carbon fiber weaving machine is its ability to precisely control fiber orientation and distribution, which is crucial for achieving desired mechanical properties in the final composite. Compared to alternative methods, rapier looms offer exceptional flexibility in weaving patterns, allowing for complex 2D and 3D structures. For example, in aggressive environments like those found in industrial settings, carbon fiber composites produced by these machines offer superior anti-corrosion properties compared to traditional metals, significantly reducing maintenance costs and increasing operational safety. Furthermore, the inherent design of these looms often incorporates features that reduce energy consumption per woven meter, contributing to both economic efficiency and environmental sustainability. This makes the carbon fibre weaving machine an indispensable asset for forward-thinking manufacturers.

Manufacturer Comparison and Custom Solutions: Tailoring to Your Needs

When selecting a carbon fiber weaving loom, prospective buyers face a critical decision among various manufacturers, each offering distinct advantages. Key differentiators often include machine robustness, level of automation, after-sales support, and customization capabilities. Reputable manufacturers distinguish themselves through adherence to international standards like CE certification and a proven track record of delivering reliable machinery. For instance, some manufacturers might specialize in high-speed production for automotive applications, while others focus on producing complex 3D preforms for aerospace. Understanding the specific needs of a project is crucial for effective vendor selection.

A crucial aspect of our offering is the provision of highly customized solutions. Recognizing that standard models may not always meet unique production demands, we collaborate closely with clients to develop bespoke carbon fiber machine configurations. This can involve modifying weaving widths, incorporating specialized take-up and let-off systems for delicate fibers, or integrating advanced control software for specific pattern generation. Our technical team, with decades of experience, leverages in-depth industry knowledge to design solutions that optimize efficiency and output for niche applications. For instance, a client requiring ultra-thin carbon fiber veil for stealth applications would need different specifications compared to one producing robust carbon reinforcement for bridge structures. Our ability to tailor the carbon fiber weaving loom to these precise requirements sets us apart.

Product Specifications and Performance Data: Carbon Fiber Mesh Rapier Loom

Our Carbon Fiber Mesh Rapier Loom is designed to meet the rigorous demands of advanced composite manufacturing, delivering consistent quality and high productivity. The following table provides a detailed overview of its key technical specifications, demonstrating its capability to produce superior carbon fiber mesh for a multitude of industrial applications. These parameters are a result of extensive R&D and field testing, ensuring optimal performance under continuous operation. The robust frame construction and precision-engineered components contribute to minimal vibration and high operational stability, crucial for maintaining fabric integrity when weaving delicate carbon filaments.

| Parameter | Specification |

|---|---|

| Nominal Weaving Width | 1500mm - 3600mm (Customizable) |

| Weft Insertion Rate | Up to 450 Picks Per Minute (PPM) |

| Shedding Motion | Electronic Dobby (16-20 Shafts) / Electronic Jacquard (Optional) |

| Weft Selection | 2-8 Color Electronic Weft Selector |

| Weft Density Range | 5 - 100 Picks/cm (Adjustable) |

| Warp Beam Diameter | 800mm (Standard), 1000mm (Optional) |

| Take-up/Let-off System | Electronic Negative Let-off, Electronic Take-up |

| Power Consumption | Avg. 5.5 - 7.5 kW (depending on width and speed) |

| Machine Weight | Approx. 4500 - 8000 kg (depending on configuration) |

| Applicable Fibers | Carbon Fiber, Basalt Fiber, Glass Fiber, Aramid Fiber, etc. |

The robust construction of this carbon fiber weaving machine, utilizing high-grade steel and precision-machined components, ensures extended operational life and minimal maintenance requirements. Its energy-efficient design also contributes to lower operating costs, making it a sustainable choice for large-scale production. This particular carbon fiber weaving loom has demonstrated superior performance in producing uniform mesh structures, which is critical for applications demanding consistent mechanical properties across the entire composite part.

Real-World Impact: Application Cases and Customer Success Stories

Our Carbon Fiber Mesh Rapier Loom has been successfully deployed in various challenging industrial environments, consistently delivering high-quality output and contributing to our clients' success. One notable case involved a leading manufacturer of wind turbine blades in Europe. They required a solution capable of producing large, seamless carbon fiber fabrics with precise fiber orientation to enhance the structural integrity and aerodynamic efficiency of their next-generation blades. Our specialized carbon fiber machine was customized to handle extra-wide weaving requirements and integrated with advanced tension control systems, resulting in a 15% increase in production efficiency and a significant reduction in material waste, leading to substantial cost savings.

Another compelling example is a high-performance sports equipment company that needed a robust yet flexible carbon fiber weaving loom for producing composite components for racing bicycles and high-end tennis rackets. The challenge was to achieve intricate weave patterns and varying densities within a single fabric piece to optimize stiffness in critical areas while maintaining flexibility elsewhere. Our loom’s advanced electronic jacquard system and multi-weft selection capabilities enabled them to achieve these complex designs with unprecedented precision, leading to a 20% improvement in product performance and a stronger market position. These case studies underscore the transformative potential of investing in cutting-edge carbon fiber weaving technology.

Trust and Support: FAQ, Delivery, Warranty, and Client Services

Building long-term partnerships with our clients is at the core of our business philosophy. We understand that investing in a carbon fiber machine is a significant decision, and we are committed to providing comprehensive support every step of the way, from initial consultation to after-sales service. Our commitment to quality is reflected in our adherence to ISO and CE certifications, validating our manufacturing processes and product reliability. We have a dedicated team of engineers and technical support staff ready to assist with installation, training, and troubleshooting, ensuring seamless integration into your existing production lines.

Frequently Asked Questions (FAQ)

-

Q: What types of carbon fibers can this loom process?

A: Our Carbon Fiber Mesh Rapier Loom is versatile and compatible with various carbon fiber types, including standard modulus, intermediate modulus, and high modulus fibers, as well as glass fiber, aramid fiber, and basalt fiber. -

Q: What is the typical delivery period for a custom loom?

A: Standard models typically have a lead time of 60-90 days from order confirmation. For highly customized solutions, the delivery period may extend to 120-180 days, depending on the complexity of modifications. -

Q: What warranty is provided with the machine?

A: We offer a comprehensive 12-month warranty on all mechanical and electrical components from the date of installation. Extended warranty options and maintenance contracts are also available. -

Q: How does your loom contribute to energy efficiency?

A: Our looms incorporate advanced motor control systems (e.g., servo motors), optimized mechanical designs, and energy recovery mechanisms, significantly reducing overall power consumption compared to older models, leading to notable operational cost savings.

Our commitment extends beyond the sale, with dedicated customer support channels, including remote diagnostics and on-site technical visits, ensuring your operations run smoothly and efficiently. We believe that robust support is as critical as the machinery itself.

References

- Jones, R.M. "Mechanics of Composite Materials." Taylor & Francis, 2018.

- Peters, S.T. "Handbook of Composites." Springer, 2017.

- Chou, T.W. "Microstructural Design of Fiber Composites." Cambridge University Press, 2019.

- Gibson, R.F. "Principles of Composite Material Mechanics." CRC Press, 2016.

- ISO 9001:2015 Quality management systems - Requirements. International Organization for Standardization.

Pervious