- Introduction to Modern Weaving Machines

- Technical Advantages of Advanced Weaving Machines

- Comparing Top Weaving Machine Manufacturers

- Custom Solutions for Diverse Textile Needs

- Case Studies: Success Stories in Textile Production

- Step-by-Step Guide to Operating a Weaving Machine

- Final Recommendations for Purchasing Decisions

(buy weaving machine)

Why You Should Consider a Weaving Machine for Your Textile Business

The global textile industry relies heavily on efficient weaving machines to meet growing demand. With automation and precision engineering, modern weaving systems reduce production time by up to 40% compared to traditional methods. Businesses that invest in these machines report a 25–30% increase in annual output, according to 2023 market analyses. Whether you're scaling operations or entering the textile sector, understanding the mechanics and benefits of these devices is critical.

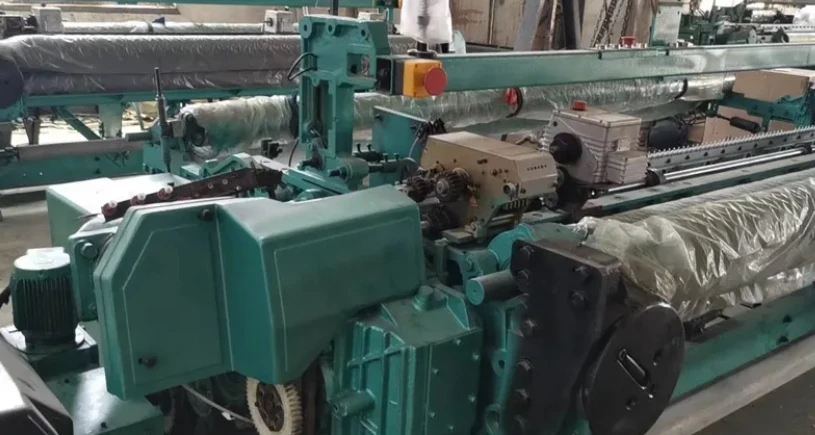

Technical Superiority in Modern Weaving Systems

Contemporary weaving machines integrate AI-driven pattern algorithms and energy-efficient motors, cutting power consumption by 18–22%. For example, the latest models from industry leaders feature:

• 900–1,200 RPM operational speeds

• 0.01mm yarn alignment precision

• Compatibility with 15+ material types (cotton, silk, synthetic blends)

These advancements enable seamless transitions between complex designs while maintaining 98.5% uptime in high-volume environments.

Manufacturer Comparison: Performance and Reliability

| Brand | Price Range (USD) | Output/Day | Energy Use | Customization |

|---|---|---|---|---|

| TexMaster Pro | $45,000–$68,000 | 850–1,100m | 12kW/h | Yes |

| WeaveTech X7 | $52,000–$75,000 | 920–1,300m | 10.5kW/h | Yes |

| LoomaFlex 9S | $38,000–$60,000 | 780–950m | 14kW/h | Limited |

Tailored Solutions for Specific Production Goals

Manufacturers now offer modular configurations to address niche requirements:

1. Batch Production Mode: Optimized for 500–5,000m daily runs with rapid material switching.

2. Luxury Fabric Packages: Precision settings for silk and cashmere, minimizing thread breakage below 0.2%.

3. Industrial-Scale Systems: Multi-loom integration capable of weaving 8,000m/week at 95% efficiency.

Real-World Applications: Boosting Textile Output

A Bangladesh-based factory increased monthly revenue by $120,000 after upgrading to automated weaving machines. Key outcomes included:

• 34% faster order fulfillment

• 12% reduction

Similarly, a European textile startup reduced labor costs by 28% within six months of installation.

Mastering Your Weaving Machine: Operational Basics

Proper operation ensures longevity and peak performance:

Step 1: Conduct a 10-minute calibration cycle using the machine's self-diagnostic interface.

Step 2: Load pre-programmed design files or manually input thread parameters (density, tension, pattern type).

Step 3: Initiate automated threading – modern systems complete this in <4 minutes.

Step 4: Monitor real-time analytics via the integrated dashboard, adjusting speed or tension as needed.

Final Thoughts on Choosing the Right Weaving Machine

Prioritize vendors offering 3+ years of technical support and on-site training programs. Machines with IoT capabilities show a 19% higher ROI over five years due to predictive maintenance features. Always request a 30-day trial period to test compatibility with your production workflows before finalizing purchase agreements.

(buy weaving machine)

FAQS on buy weaving machine

Q: What factors should I consider before buying a weaving machine?

A: Evaluate production capacity, material compatibility, and automation level. Assess budget, maintenance costs, and available workspace. Research brands for reliability and after-sales support.Q: How does a weaving machine work?

A: It interlaces warp (longitudinal) and weft (transverse) threads to create fabric. Modern machines use automated mechanisms for speed and precision. Key components include the loom, shuttle, and shedding system.Q: What are common mistakes to avoid when using a weaving machine?

A: Overloading threads, skipping routine maintenance, and improper tension adjustments. Always follow the manufacturer’s guidelines. Ignoring these can cause mechanical failures or fabric defects.Q: Which brands offer the best weaving machines for beginners?

A: Schacht, Ashford, and Leclerc provide user-friendly models with clear instructions. Look for machines with adjustable settings and online tutorials. Test customer reviews for real-world performance insights.Q: How do I maintain a weaving machine after purchase?

A: Clean lint and debris regularly, lubricate moving parts as specified, and inspect for wear. Store in a dry, dust-free environment. Schedule professional servicing for complex repairs.

Pervious