- Overview of Direct Textile Printing Technology

- Key Technological Advancements

- Competitive Analysis: Leading Manufacturers

- Cost Considerations and Pricing Strategies

- Custom Solutions for Diverse Applications

- Real-World Implementation Case Studies

- Future Prospects in Textile Printing Machinery

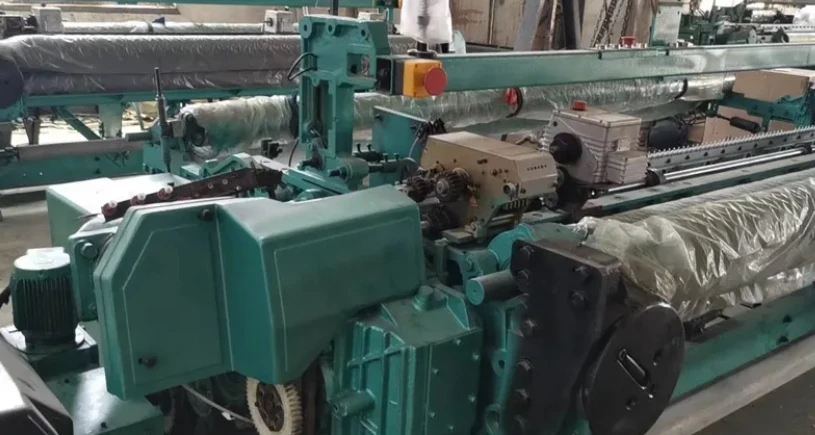

(direct textile printing machine)

Understanding Direct Textile Printing Machine Innovations

The direct textile printing machine

market has grown by 18% annually since 2020, driven by demand for sustainable, high-speed production. Unlike traditional methods, these machines eliminate pre-treatment steps, reducing water consumption by 60-70%. Modern systems achieve resolutions up to 2,400 dpi, enabling intricate designs on natural and synthetic fabrics.

Technological Advancements Redefining Efficiency

Contemporary models integrate AI-powered color matching systems that reduce ink waste by 35%. The table below compares critical performance metrics:

| Feature | Standard Model | Premium Model | Industrial Model |

|---|---|---|---|

| Print Speed | 50 m²/hr | 120 m²/hr | 300 m²/hr |

| Ink Consumption | 12 ml/m² | 8 ml/m² | 6.5 ml/m² |

| Energy Use | 3.2 kW/h | 4.8 kW/h | 7.5 kW/h |

Manufacturer Comparison: Capabilities and Pricing

Leading brands demonstrate distinct specializations:

| Brand | Price Range | Speed (m²/hr) | Warranty | Customization |

|---|---|---|---|---|

| TexPrint Pro | $85k-$120k | 90-150 | 3 years | Full |

| DigiFab Ultra | $140k-$220k | 200-280 | 5 years | Modular |

| EcoInk Master | $75k-$95k | 60-110 | 2 years | Limited |

Cost Optimization Strategies for Businesses

Mid-range models ($90k-$150k) typically achieve ROI within 14-18 months through:

- 35-40% reduction in manual labor costs

- 22% faster order turnaround

- 15% lower material waste vs. rotary printing

Tailored Solutions for Industry-Specific Needs

Custom configurations address unique requirements:

- Fashion Sector: 6-color systems for gradient effects

- Home Textiles: Oversized print beds (up to 3.5m)

- Industrial Applications: Fire-retardant ink compatibility

Success Stories Across Market Segments

A sportswear manufacturer increased production capacity by 170% after implementing DigiFab's dual-printhead system, while reducing defective output from 8.2% to 1.7%.

Direct Textile Printing Machine Market Projections

With 65% of textile producers planning digital adoption by 2025, advanced direct printing systems are projected to capture 42% of the global textile decoration market. Emerging technologies like nanotechnology inks promise to expand color gamuts by 30% while maintaining eco-certifications.

(direct textile printing machine)

FAQS on direct textile printing machine

Q: What is a direct textile printing machine?

A: A direct textile printing machine applies ink directly onto fabrics using digital technology, enabling high-precision and customizable designs. It eliminates the need for traditional screens or plates.

Q: How does a textile printing machine work?

A: Textile printing machines use digital files to transfer designs onto fabric via inkjet or dye-sublimation methods. They ensure fast production and vibrant color reproduction on various textiles.

Q: What factors affect textile printing machine price?

A: Prices depend on machine size, printing speed, ink technology, and brand. Advanced models with multi-color capabilities or larger formats typically cost more.

Q: Why choose a direct textile printing machine over traditional methods?

A: Direct machines offer faster setup, lower waste, and greater design flexibility. They are ideal for small batches and complex patterns compared to screen printing.

Q: What is the average price range for a textile printing machine?

A: Entry-level models start around $10,000, while industrial-grade machines can exceed $100,000. Maintenance and ink costs should also be factored into the budget.

Pervious