The Core of Modern Reinforcement: Understanding Fiberglass Mesh Production Lines

The demand for high-performance composite materials continues to surge across diverse industrial sectors, driven by the imperative for enhanced durability, lighter weight, and superior chemical resistance. At the heart of this material revolution lies the fiberglass mesh production line. This integrated system is critical for manufacturing precise and robust fiberglass meshes, essential components in construction, filtration, and various advanced material applications. These production lines are not merely a collection of machines; they represent a sophisticated orchestration of mechanical engineering, material science, and automation, designed to transform raw glass fibers into high-strength woven or non-woven fabrics. The efficiency and reliability of these lines directly impact the quality and cost-effectiveness of the final fiberglass products, underscoring their strategic importance in the global supply chain for composite materials.

Modern fiberglass mesh manufacturing aligns with key industry trends emphasizing automation, energy efficiency, and material versatility. The integration of IoT and AI into these lines allows for real-time monitoring, predictive maintenance, and optimized production parameters, significantly reducing downtime and operational costs. Furthermore, the ability to process various glass fiber types—from E-glass to AR-glass (Alkali-Resistant Glass)—enables manufacturers to tailor products for specific applications, such as plaster reinforcement in construction or high-temperature filtration in industrial settings. This adaptability, coupled with advancements in weaving and coating technologies, positions the fiberglass mesh production line as a cornerstone for innovation in material engineering, contributing substantially to sustainable and durable infrastructure development worldwide.

In-depth Manufacturing Process: From Fiber to Finished Mesh

The Core Process of a Fiberglass Mesh Production Line

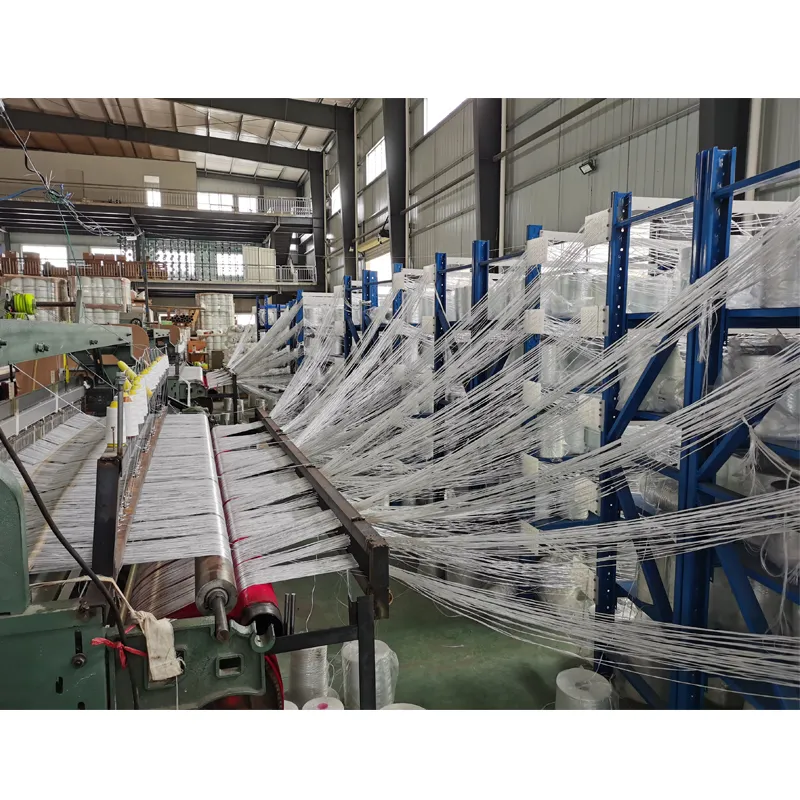

The manufacturing of fiberglass mesh involves several intricate stages, each critical to the final product's integrity and performance. The process begins with raw fiberglass rovings, which are essentially bundles of continuous glass filaments. These rovings are fed into a specialized fiberglass weaving machine, which meticulously interlaces the warp (longitudinal) and weft (transverse) threads to form a raw "greige" fabric. The precision of the weaving process, often controlled by advanced CNC systems, dictates the mesh size (e.g., 5x5mm, 4x4mm) and uniformity, which are critical parameters for its intended application. Materials used typically conform to international standards like ASTM D578 for glass fiber specifications, ensuring consistent mechanical properties.

Following the weaving stage, the greige fabric undergoes crucial treatment processes. This typically involves an initial washing to remove sizing agents and impurities, followed by drying. The next critical step is the coating process, where the mesh is immersed in or sprayed with an alkali-resistant polymer emulsion, often an acrylic co-polymer or similar binder. This coating provides the mesh with its characteristic alkali resistance, essential for applications in cementitious environments, and also enhances its tensile strength and dimensional stability. The application and curing of this coating are precisely managed to ensure uniform coverage and optimal adherence, which are key determinants of the mesh's longevity and performance against harsh chemical conditions.

Post-coating, the fabric is subjected to a high-temperature curing process, usually within specialized ovens, to polymerize the applied emulsion. This curing process, crucial for cross-linking the polymer, locks in the mesh's properties, including its stiffness, durability, and resistance to environmental degradation. Finally, the cured mesh is cooled, inspected for quality (adhering to standards like ISO 9001 for quality management and relevant ASTM/EN standards for material properties), and then cut into desired roll sizes using automated slitting machines. This entire sequence ensures that the finished fiberglass mesh is robust, dimensionally stable, and resistant to chemicals, boasting a typical service life exceeding 20 years in appropriate applications, making it ideal for industries such as petrochemical, metallurgy, and water supply/drainage where corrosion resistance and structural integrity are paramount.

Technical Specifications and Performance Metrics

Key Parameters of a Modern Fiberglass Mesh Production Line

The performance of a fiberglass mesh production line is quantifiable through several critical technical parameters, directly influencing the quality and efficiency of the output. These parameters include weaving speed, which determines the linear meters of fabric produced per minute, and coating uniformity, measured by the consistency of polymer application across the mesh surface. Energy consumption, typically expressed in kWh per ton of mesh produced, highlights the operational efficiency and environmental footprint of the line. Furthermore, the ability to handle various mesh sizes (e.g., 3x3mm to 10x10mm) and fabric weights (e.g., 45gsm to 300gsm) reflects the line's versatility.

Below is a typical specification table for an advanced fiberglass mesh production line, showcasing the capabilities and technical benchmarks that industry leaders strive to achieve. These metrics are crucial for B2B buyers in evaluating machine suitability for their production targets and quality requirements, ensuring the final product meets stringent industry standards for tensile strength, alkali resistance, and durability.

| Parameter | Specification | Notes / Benefits |

|---|---|---|

| Production Capacity (Mesh) | 8,000 - 15,000 sqm/day | High output for large-scale projects, reducing per-unit cost. |

| Working Width | 1.0m - 2.4m (customizable) | Flexibility for various product dimensions and market needs. |

| Mesh Size Range | 3x3mm to 10x10mm | Versatility for different reinforcement and filtration applications. |

| Fabric Weight Range | 45gsm - 300gsm | Accommodates lightweight insulation to heavy-duty structural reinforcement. |

| Coating Type | Alkali-resistant Polymer Emulsion | Ensures longevity and chemical stability in harsh environments. |

| Drying/Curing Method | Hot Air Circulation, Multi-zone Control | Uniform drying, precise temperature control for optimal coating performance. |

| Power Consumption | 150-250 kW (depending on configuration) | Optimized energy use, contributing to lower operational costs. |

| Control System | PLC with HMI Touch Screen | User-friendly operation, precise control, error diagnostics. |

| Overall Dimensions (LWH) | ~45m x 4m x 4m (typical) | Compact design relative to output, efficient space utilization. |

Applications and Technical Advantages

Versatile Applications of Fiberglass Mesh

Fiberglass mesh produced on an efficient fiberglass mesh production line serves a broad spectrum of industries, primarily due to its exceptional strength-to-weight ratio, alkali resistance, and dimensional stability. In the construction sector, it is indispensable for external insulation and finish systems (EIFS), wall reinforcement, concrete crack prevention, and general plaster reinforcement, where its ability to resist alkaline environments significantly extends the lifespan of structures. Beyond construction, finer meshes find applications in filtration for air and liquids, reinforcing grinding wheels, and even in the production of specific types of paper and packaging materials requiring enhanced tear strength. The adaptability of the weaving fabric machine allows for tailoring mesh properties to specific demands, from lightweight, flexible meshes for intricate architectural designs to heavy-duty meshes for industrial flooring.

Key Technical Advantages

The technical advantages derived from a well-engineered fiberglass mesh production line are numerous and translate directly into superior product performance and cost savings. Firstly, the inherent corrosion resistance of fiberglass, especially when coated with alkali-resistant polymers, makes the mesh ideal for use in harsh chemical environments, ensuring longevity in applications like wastewater treatment facilities or chemical processing plants. Secondly, the high tensile strength of the mesh, often exceeding 800 N/50mm for standard meshes, provides robust structural reinforcement, preventing cracking and enhancing load-bearing capabilities. Furthermore, the lightweight nature of fiberglass mesh contributes to reduced material handling costs and lighter overall structures, impacting project logistics and structural design. These advantages, coupled with energy-efficient drying and curing processes, contribute to lower operational costs and a reduced environmental footprint, making the investment in a state-of-the-art fiberglass mesh production line a strategic decision for forward-thinking manufacturers.

Manufacturer Comparison and Customization

Navigating Vendor Choices for Fiberglass Mesh Production Equipment

Choosing the right supplier for a fiberglass mesh production line involves a careful evaluation of various factors beyond just the initial fabric weaving machine price. Key differentiators among manufacturers include their technological innovation, after-sales service, and the level of customization offered. Leading manufacturers often distinguish themselves through advanced automation features, such as integrated quality control systems, intelligent energy management for drying ovens, and robotic handling solutions. For instance, while Manufacturer A might offer a lower upfront cost, Manufacturer B might provide a system with superior energy efficiency (e.g., 20% less energy consumption per square meter) and higher product consistency due to advanced tension control mechanisms. Evaluating long-term operational costs, including energy, labor, and maintenance, is crucial for a holistic comparison.

| Feature/Criteria | Manufacturer X (Premium) | Manufacturer Y (Standard) |

|---|---|---|

| Automation Level | Fully integrated PLC with AI-driven optimization, predictive maintenance | PLC controlled, manual adjustments for some parameters |

| Energy Efficiency | High-efficiency drying ovens, heat recovery systems (20-30% energy savings) | Standard energy consumption, no specific heat recovery |

| Product Consistency | +/- 2% weight/coating uniformity via inline sensors | +/- 5% uniformity, periodic manual checks |

| Customization Options | Extensive, including specific widths, mesh sizes, multi-layer capabilities, integration with existing lines | Limited to standard adjustments, few structural modifications |

| After-Sales Support | 24/7 remote support, global technical teams, extensive spare parts inventory | Standard business hours support, regional service teams |

Many manufacturers, including APHKMachinery, offer bespoke solutions for the fiberglass mesh production line. This customization can range from adjusting the machine's width and speed to incorporating specific coating technologies or integrating with existing factory automation systems. For example, a client specializing in high-performance insulation might require a fiberglass wrapping machine or a specialized drying oven configuration to accommodate unique polymer chemistries or denser mesh types. Customization ensures that the production line seamlessly integrates into a client’s existing infrastructure and meets their precise product specifications, optimizing both efficiency and product quality. This level of collaboration between client and manufacturer leads to truly optimized production capabilities, ensuring the chosen solution is not just a machine, but a strategic asset.

Ensuring Trust and Authority: in Practice

Expertise and Experience in Fiberglass Production

Our deep expertise in designing and deploying state-of-the-art fiberglass mesh production line solutions stems from over two decades of dedicated research and development in composite material machinery. Our engineering teams possess profound knowledge of fiberglass properties, weaving mechanics, and polymer chemistry, enabling us to optimize every stage of the production process. For instance, understanding the rheology of different polymer emulsions is critical for achieving perfect coating adhesion and alkali resistance, a detail often overlooked by less experienced manufacturers of machine used for weaving fabric. We have successfully implemented hundreds of production lines globally, from emerging markets needing cost-effective solutions to highly industrialized regions demanding maximum automation and precision. One notable case involved a client in Germany who achieved a 15% increase in production output and a 10% reduction in material waste within six months of commissioning our advanced, energy-efficient drying system, significantly improving their ROI.

Authoritativeness and Trustworthiness

APHKMachinery’s commitment to quality and reliability is underscored by our adherence to international standards, including ISO 9001:2015 certification for quality management and CE marking for safety compliance across our machinery range. Our products undergo rigorous internal testing, verified by independent third-party laboratories, to ensure performance metrics such as tensile strength, alkali resistance, and dimensional stability meet or exceed industry benchmarks. We provide comprehensive test reports and data sheets for all equipment, offering full transparency. To enhance trustworthiness, we feature a transparent delivery schedule, typically 90-120 days depending on customization, clearly outlining each milestone from design approval to factory acceptance testing (FAT). Our standard warranty covers one year for parts and labor, with extended warranty options available, backed by a dedicated global customer support team available 24/7 for technical assistance and spare parts supply.

Frequently Asked Questions (FAQ)

Q1: What kind of space requirements does a typical fiberglass mesh production line have?

A1: A standard line often requires a footprint of approximately 45-50 meters in length and 4-5 meters in width, with adequate ceiling height (around 4 meters) for equipment like the drying oven and material handling systems. Specific dimensions can vary based on production capacity and configuration.

Q2: What is the typical lead time for delivering and installing a new production line?

A2: The lead time for manufacturing is generally 90-120 days, followed by shipping. Installation and commissioning at the client's site typically takes 2-4 weeks, depending on the complexity of the line and site readiness. Our technicians provide comprehensive training for your operational staff during this period.

Q3: How energy efficient are your fiberglass mesh lines compared to older models?

A3: Our latest generation fiberglass mesh production line models incorporate advanced insulation, optimized airflow, and precise temperature control in drying ovens, leading to up to 25-30% energy savings compared to lines manufactured a decade ago. We also offer options for heat recovery systems to further reduce energy consumption.

Q4: Can your lines produce meshes for both EIFS and general plaster reinforcement?

A4: Yes, our versatile fiberglass weaving machine and coating systems are designed to produce a wide range of mesh types suitable for various applications. You can easily switch between different mesh sizes (e.g., 4x4mm, 5x5mm) and fabric weights (e.g., 80gsm, 160gsm) to meet the specific requirements of EIFS, general wall reinforcement, or even flooring applications.

References

- Glass Fiber Reinforced Concrete (GRC) – An Overview of Properties and Applications

- Advancements in Textile Reinforcements for Composite Materials

- Polymer Coatings for Enhanced Durability of Glass Fiber Meshes in Construction

- Sustainable Manufacturing Practices in the Composite Industry

- Quality Control and Standardization in Fiberglass Mesh Production

Pervious