Product Overview: Fiberglass Mosquito Net Production Line

The Fiberglass Mosquito Net Machine is a specialized industrial system designed to manufacture high-quality window screens and mosquito nets. This production line integrates multiple machines, including the fiberglass yarn coating machine, warping machine, weaving machine, and shaping machine, to ensure precision, durability, and efficiency. The system is tailored for producing 14×17, 16×18, and 20×20 mesh specifications, meeting global standards for residential and commercial applications.

Key Components and Technical Specifications

1. Fiberglass Yarn PVC Coating Machine

The Fiberglass Yarn PVC Coating Machine enhances the mechanical properties of glass fiber yarn by applying a PVC resin coating. This process increases tensile and flexural strength, while also improving surface gloss and roundness. The machine features a 26-meter length, 2-meter height, and 1.8-meter width, with a power rating of 18 kW. It produces 800 kg of coated yarn daily (28-30 threads), ensuring high output for industrial-scale operations.

2. Warping Machine

The Warping Machine is crucial for preparing warp yarns for weaving. It includes models like the 260, 280, and 320 types, with the 260 model featuring a 4.2m×1.75m×1.25m size, 15 kW power, and 800-1200 meters/hour winding speed. Key advantages include high stability, automation, and uniform warp tension, ensuring seamless weaving processes.

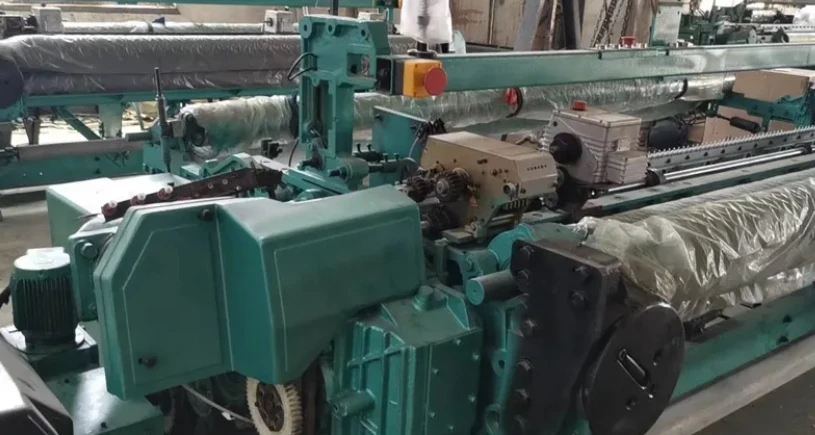

3. Weaving Machine

The Weaving Machine produces flat, square-mesh screens with high efficiency. The 260 model has a 4.2m×1.8m×1.45m size, 1.5 kW power, and 135-165 cycles/minute speed. It supports electronic warp sending and winding, offering flexibility for customized mesh patterns.

4. Shaping Machine

The Shaping Machine uses high-temperature ovens (320 meters long, 32 meters wide, 4.5 meters high) to bond warp and weft yarns. With 220 kW power, it achieves a production rate of 2000-2200 meters/hour, ensuring durability and aesthetic finish.

5. Mesh Quality Inspection Machine

This machine monitors mesh length and density, with a 2m width, 2.2 kW power, and 500 kg weight. It can support up to 8 weaving machines, ensuring consistent quality across production lines.

Product Specifications Table

| Machine Type | Size | Power | Weight | Speed | Key Features |

|---|---|---|---|---|---|

| Fiberglass Yarn PVC Coating Machine | 26m × 2m × 1.8m | 18 kW | N/A | 800 kg/day | PVC coating, high tensile strength |

| Warping Machine (260 Type) | 4.2m × 1.75m × 1.25m | 15 kW | 2 tons | 800-1200 m/h | High automation, uniform tension |

| Weaving Machine (260 Type) | 4.2m × 1.8m × 1.45m | 1.5 kW | 1.8 tons | 135-165 cycles/min | Flat mesh, square pattern |

| Shaping Machine | 320m × 32m × 4.5m | 220 kW | N/A | 2000-2200 m/h | High-temperature bonding |

| Mesh Quality Inspection Machine | 3100×920×1550 mm | 2.2 kW | 500 kg | N/A | 8-set support, real-time monitoring |

Applications and Industry Use Cases

The Fiberglass Mosquito Net Machine is widely used in residential and commercial sectors for producing fiberglass window screens, foldable window screens, and mosquito nets. Its durability and resistance to corrosion make it ideal for:

- Residential Use: Protecting homes from insects while maintaining airflow.

- Commercial Buildings: Ensuring hygiene and safety in offices, hotels, and public spaces.

- Industrial Applications: Manufacturing mesh for ventilation systems and filtration equipment.

According to the National Institute of Standards and Technology (NIST), advanced manufacturing systems like these are critical for improving material efficiency and reducing production waste. NIST’s research on industrial automation standards highlights the importance of precision engineering in modern manufacturing processes.

Company Background: Anping Hongke Wire Mesh Machinery Factory

Founded in Anping County, Hebei Province, Anping Hongke Wire Mesh Machinery Factory specializes in designing and manufacturing industrial machinery for mesh production. With over a decade of experience, the company focuses on innovation, quality, and customer satisfaction. Their product line includes fiberglass mesh machines, mosquito net making machines, and industrial weaving machines, catering to global markets.

The company’s commitment to industry standards is evident in their adherence to rigorous quality control measures, ensuring products meet international benchmarks for performance and safety.

Advantages of the Fiberglass Mosquito Net Machine

- High Efficiency: 24-hour production capacity of 800 kg/day for coated yarn.

- Durability: PVC-coated yarn resists UV degradation and corrosion.

- Customization: Supports multiple mesh sizes (14×17, 16×18, 20×20).

- Automation: Reduces labor costs and human error through advanced control systems.

Conclusion

The Fiberglass Mosquito Net Machine represents a significant advancement in industrial mesh production, combining precision engineering with scalable efficiency. By integrating cutting-edge technologies like PVC coating and automated weaving, Anping Hongke Wire Mesh Machinery Factory ensures its products meet the demands of modern manufacturing. As highlighted by NIST research, such systems are vital for driving innovation and sustainability in industrial processes.

Pervious