Introduction

The demand for durable and efficient mosquito netting solutions has surged in recent years, driven by the need for effective pest control in residential and commercial spaces. At the forefront of this innovation is Anping Hongke Wire Mesh Machinery Factory, a leading manufacturer of fiberglass mosquito net production lines. This article delves into the Fiberglass Mosquito Net Machine, a comprehensive system that includes a PVC Coating Machine, Warping Machine, Weaving Machine, Coating Machine, and Mesh Quality Inspection Machine. Each component is engineered to meet stringent industrial standards, ensuring the production of high-performance fiberglass mesh. This guide explores the product's features, technical specifications, applications, and the company's commitment to quality, supported by authoritative references from the National Institute of Standards and Technology (NIST).

Product Overview: Fiberglass Mosquito Net Production Line

The Fiberglass Mosquito Net Machine is a complete production line designed to manufacture fiberglass window screens and mosquito nets with exceptional strength, durability, and aesthetic appeal. The system integrates multiple specialized machines, each optimized for a specific stage of the production process. Below is an overview of the key components:

- PVC Coating Machine: Enhances the tensile and flexural strength of glass fiber yarn.

- Warping Machine: Ensures uniform tension and arrangement of warp yarn for weaving.

- Weaving Machine: Produces flat, square mesh screens with high efficiency.

- Coating Machine: Applies heat treatment to bond warp and weft yarns, improving strength and flatness.

- Mesh Quality Inspection Machine: Monitors mesh dimensions and density for quality control.

For a detailed look at the Fiberglass Mosquito Net Machine, visit the product page.

Technical Specifications and Features

The Fiberglass Mosquito Net Machine is engineered with precision to meet industrial demands. Below is a detailed breakdown of the technical specifications for each component:

PVC Coating Machine

| Parameter | Details |

|---|---|

| Machine Size | 26 meters long, 2 meters high, 1.8 meters wide |

| Power | 18 kW |

| 24-Hour Output | 800 kg (28-30 threads) |

This machine coats glass fiber yarn with PVC resin, enhancing its strength and surface finish. It uses four grinding tools and two heating cycles to ensure optimal quality. The winding machine features 40 spindles, enabling efficient operation.

Warping Machine (260 Type)

| Parameter | Details |

|---|---|

| Machine Size | L4.2m × W1.75m × H1.25m |

| Power | 15 kW |

| Weight | 2 tons (excluding yarn rack) |

| Winding Speed | 800-1200 meters/hour |

The 260 Type Warping Machine is equipped with a 63 kg magnetic powder brake, photoelectric protection, and infrared stop systems. It ensures uniform warp tension and high automation, making it ideal for large-scale production.

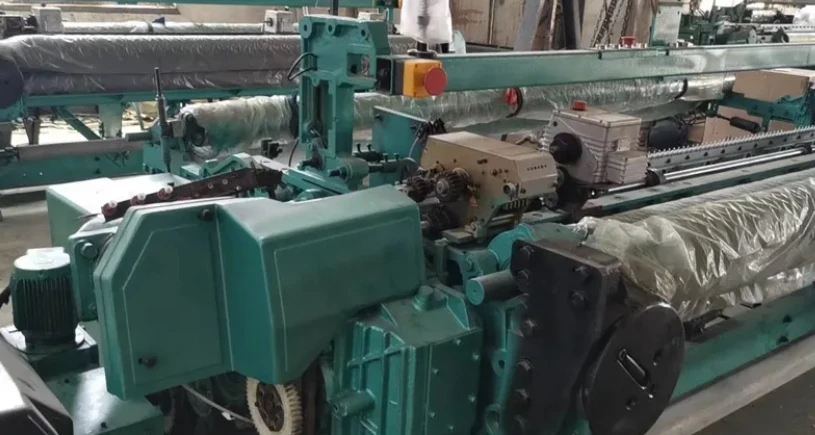

Weaving Machine (260 Type)

| Parameter | Details |

|---|---|

| Machine Size | L4.2m × W1.8m × H1.45m |

| Power | 1.5 kW |

| Weight | 1.8 tons |

| Speed | 135-165 times/minute |

The 260 Type Weaving Machine produces flat mesh surfaces with clear texture and square mesh. It features a 45 kg magnetic powder clutch and Tiger King electric control system, offering flexibility in warp sending and winding.

Coating Machine

| Parameter | Details |

|---|---|

| Machine Size | 320 meters long, 32 meters wide, 4.5 meters high |

| Power | 220 kW |

| Production Rate | 2000-2200 meters/hour |

The Coating Machine uses electric heating and four ovens to bond warp and weft yarns, enhancing the mesh's strength, durability, and flatness. It is a critical step in achieving high-quality finished products.

Mesh Quality Inspection Machine

| Parameter | Details |

|---|---|

| Width | 2 meters |

| Power | 2.2 kW |

| External Size | 3100 × 920 × 1550 mm |

| Gross Weight | 500 kg |

| Capacity | Supports 8 weaving machines |

This machine ensures real-time monitoring of mesh length and density, guaranteeing consistent quality across production batches.

Key Advantages of the Fiberglass Mosquito Net Machine

The Fiberglass Mosquito Net Machine offers several advantages that set it apart in the industry:

- High Automation: Reduces manual labor and increases production efficiency.

- Uniform Tension: Ensures consistent mesh quality with minimal defects.

- Durability: The PVC coating and heat treatment enhance the mesh's lifespan.

- Scalability: Supports large-scale production with high output rates.

- Quality Control: The inspection machine guarantees adherence to industry standards.

For more details on the advantages of fiberglass mosquito nets, visit the product page.

Applications and Industry Impact

The Fiberglass Mosquito Net Machine is widely used in various sectors, including:

- Residential: Protecting homes from insects while maintaining ventilation.

- Commercial: Enhancing the safety of offices, hotels, and public spaces.

- Industrial: Providing durable mesh for machinery and equipment enclosures.

The production line's ability to create 14 × 17, 16 × 18, and 20 × 20 mesh specifications ensures versatility for different applications. According to the National Institute of Standards and Technology (NIST), precision in manufacturing processes is critical for maintaining product quality and performance [1].

About Anping Hongke Wire Mesh Machinery Factory

Anping Hongke Wire Mesh Machinery Factory (安平县宏科丝网机械有限公司) is a trusted name in the production of industrial machinery for fiberglass mesh and mosquito netting. With years of expertise, the company specializes in delivering high-quality, reliable machinery that meets global standards. Their commitment to innovation and customer satisfaction has positioned them as a leader in the industry.

For more information about the company, visit the Anping Hongke website.

Conclusion

The Fiberglass Mosquito Net Machine by Anping Hongke Wire Mesh Machinery Factory represents a significant advancement in the production of durable, high-performance mosquito nets. With its advanced technical specifications, automation capabilities, and robust quality control, this production line is a valuable asset for manufacturers seeking to meet market demands. As highlighted by the National Institute of Standards and Technology (NIST), adherence to precision and innovation is essential for driving industry progress [1].

References

[1] National Institute of Standards and Technology. (n.d.). Driving Innovation. https://www.nist.gov/

Pervious