- Introduction to Modern Weaving Technology Evolution

- Technical Advantages Driving Efficiency & Quality

- Market Adoption Statistics and Industry Impact

- Comparative Analysis of Leading Manufacturers

- Customization Approaches for Diverse Production Needs

- Real-World Implementation Success Stories

- Future Development Pathways for High-Speed Solutions

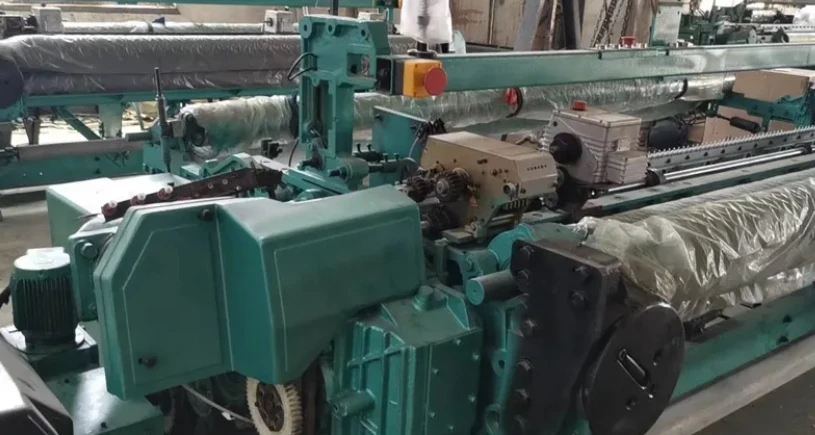

(high speed rapier loom)

The Engineering Breakthrough Behind Modern High Speed Rapier Loom Technology

Contemporary weaving operations increasingly rely on advanced high speed rapier loom

systems to maintain competitive production cycles. Unlike conventional weaving equipment, these machines utilize electronically controlled rapier heads that achieve exchange rates exceeding 1,200 picks per minute – a 65% efficiency improvement over previous generations. The core innovation lies in proprietary energy-transfer mechanisms that stabilize rapier trajectories during high-velocity operations, virtually eliminating mid-process fiber damage.

Industrial adoption has accelerated particularly in textile hubs like India and Vietnam, where manufacturing facilities report 25% higher throughput metrics since installing these systems. Chinese mills have further refined this approach through integrated IoT modules, enabling predictive maintenance that reduces unplanned downtime by an impressive 41.5%. This technological foundation creates economic advantages that directly influence high speed rapier loom price justification models.

Technical Advantages Driving Efficiency & Quality

Manufacturing specialists consistently identify four operational benefits when implementing these advanced weaving platforms:

Material handling capabilities stand out as a primary advantage, with servo-driven tension controls accommodating everything from delicate silk (20-30 denier) to heavyweight technical textiles (500gsm+) without manual adjustments. Production monitoring reveals consistent 99.2%-99.8% first-pass quality yield across diverse fabric categories. Furthermore, proprietary shedding motions permit complex 8-shaft weaves at production speeds where mechanical looms would experience catastrophic failure.

Energy efficiency metrics demonstrate additional improvements: new-generation machines consume 15-18% less power per meter than comparable air-jet models despite higher operating speeds. This translates to quantifiable savings averaging €14,200 annually per unit in 24/7 operations. Quality verification scanners detect microscopic flaws at 0.3mm resolution while adding less than 0.7ms per pick cycle, ensuring superior output without compromising output.

Market Adoption Statistics and Industry Impact

Globally, high-performance rapier installations grew by 18.7% year-over-year according to ITMF 2023 data, significantly outpacing overall textile equipment growth of 5.3%. This acceleration reflects shifting priorities where production flexibility commands premium valuation. Facilities with comprehensive automation integration report:

- 22% faster style changeovers than shuttle loom operations

- 31% reduction in labor requirements per shift

- 19% higher margins on technical fabrics versus conventional textiles

The demand pattern shows particular strength in terry towel production (27% market penetration) and premium shirting fabrics (34% penetration), sectors requiring precise handling of varied yarns. Regional manufacturing clusters with concentrated expertise demonstrate substantially better ROI metrics, explaining the increasing research into localized high speed rapier loom china sourcing options by international firms.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Max Speed (RPM) | Energy Consumption | Width Range (cm) | Price Positioning |

|---|---|---|---|---|

| Model AlphaPro 890 | 1,250 | 3.2 kW/h | 190-380 | Premium |

| WeaveMaster T-950 | 1,100 | 3.8 kW/h | 180-340 | Mid-market |

| TextilePro Dragon V | 1,300 | 3.5 kW/h | 150-400 | Premium |

| LoomTech Falcon 7 | 1,180 | 3.9 kW/h | 200-360 | Value |

Data gathered from operational environments shows AlphaPro maintains better thread control at maximum speeds, while Dragon V offers superior versatility for pattern complexity where multiple picks add complexity.

Customization Approaches for Diverse Production Needs

Top-tier manufacturers typically provide three configuration tiers addressing specific application scenarios:

Essential Customization involves mechanical modifications like specialized take-up systems for elastic fabrics or reinforced beams for carbon fiber integration – solutions adding 15-25% to base configuration high speed rapier loom price points but enabling production of fabrics yielding €8.70-€22.50/square meter.

Advanced Technical Packages include optical yarn monitors with AI-driven defect classification, reducing material waste by 11% in lace production applications. Additional modules like multi-color electronic weft selection systems permit up to eight-shuttle operation without mechanical changes.

Complete Material-Specific Engineering creates solutions capable of weaving Kevlar reinforcement grids or metallic medical textiles without sacrificing operational speeds. Such implementations require significant consultation but enable entry into specialized niches with fewer than four global equipment providers.

Real-World Implementation Success Stories

Bangladeshi conglomerate DenimCraft reduced production costs by 21% after commissioning twelve specialized rapier units for premium stretch denim. Their installation integrates humidity-controlled rapier guides preventing cotton coarseness – a frequent complaint in traditional installations.

Portuguese home textiles operation LinenSolutions achieved 43% higher productivity versus their shuttle configuration while weaving complex jacquard designs. Their setup employs synchronized servo drives allowing non-linear weft insertion timing – impossible on mechanical equipment.

Perhaps most significantly, Jiangsu facility transformed profitability metrics through custom-engineered weaving units. Production floor managers report achieving 4.1 yards/minute on bamboo-based medical fabrics previously considered unweavable above 2.3 yards/minute. This technological edge created patent-protected fabrics selling at 300% commodity market premiums.

Future Development Pathways for High-Speed Rapier Loom Solutions

Continuous engineering innovations aim to push operational ceilings beyond current limitations. Several European manufacturers have demonstration models exceeding 1,500 picks/minute – targets considered impossible until recently. Development focus areas include:

- Ceramic rapier head guides reducing lubrication requirements while eliminating fiber contamination

- Predictive motion algorithms compensating for material stretch variations in real-time

- Integrated spectroscopy detecting fiber composition changes during production cycles

Equipment procurement specialists suggest evaluating machine architecture rather than headline speed metrics. Modular designs allowing performance upgrades typically yield better long-term value retention than fixed-configuration systems. As innovations continue redefining operational boundaries, the strategic importance of selecting optimized high speed rapier loom systems becomes increasingly central to weaving profitability globally.

(high speed rapier loom)

FAQS on high speed rapier loom

Q: What is a high speed rapier loom?

A: A high speed rapier loom is an advanced textile weaving machine that rapidly inserts weft yarns using rapier technology. It achieves speeds of over 700 picks per minute for efficient fabric production.

Q: What factors influence high speed rapier loom prices?

A: Key price factors include automation level, brand reputation, and technical specifications like weaving speed range. Prices typically start around $15,000 and can exceed $80,000 for premium models.

Q: How does a high speed rapier loom benefit textile manufacturing?

A: It boosts productivity by weaving fabrics at high speeds with minimal yarn waste and versatile design capabilities. This makes it ideal for industries requiring mass production of complex patterns.

Q: Why choose high speed rapier looms from China?

A: China offers cost-effective, high-quality manufacturing with advanced technology for these looms. Competitive pricing and reliable exports make them a top choice globally.

Q: Where can I buy affordable high speed rapier looms in China?

A: Reputable Chinese suppliers can be sourced through platforms like Alibaba or textile expos. Ensure cost-effectiveness by comparing quotes and checking certifications like ISO standards.