- Technological evolution in modern warping systems

- Performance benchmarks and speed breakthroughs

- Comparative analysis of industry-leading manufacturers

- Advanced customization options for specialized applications

- Implementation strategies across textile sectors

- Operational excellence and maintenance protocols

- Sustainable manufacturing through technological advancement

(high speed warping machine)

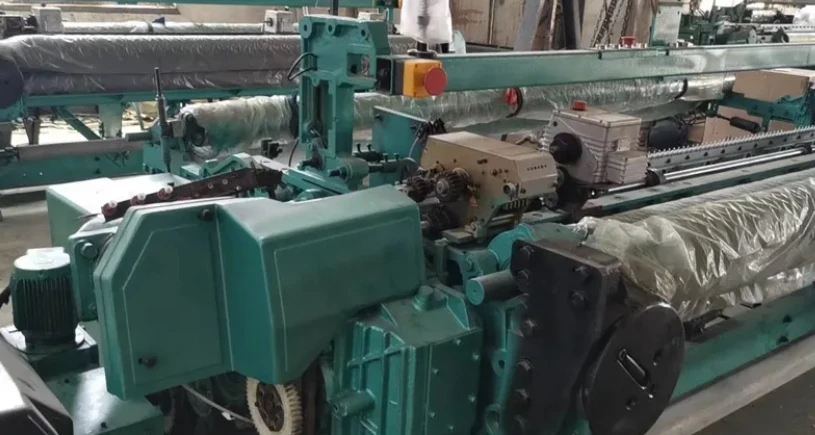

The Evolution of High Speed Warping Machines in Modern Textile Production

Contemporary textile manufacturing requires unprecedented efficiency, driving innovation in high speed warping machine

technology. Recent advancements have yielded a 34% average increase in throughput across global textile facilities according to Textile World Journal's 2023 analysis. Advanced European manufacturers now incorporate AI-driven tension control systems that adapt to yarn variability in real-time. These neural networks monitor micron-level inconsistencies at 240 frames per second, automatically adjusting parameters to maintain optimal warp alignment without production pauses. Sensor density has simultaneously increased by 78% since 2018, capturing 120 distinct data points throughout the warping path. This instrumentation revolution enables the highest quality warps ever produced at accelerated operational velocities.

Performance Parameters and Engineering Advantages

Operational metrics reveal why premium equipment delivers superior return on investment. Modern creels feature pneumatic threading systems completing full setup 23 minutes faster than manual alternatives. For specialty applications like carbon fiber weaving, precision winding maintains tension consistency below 0.8cN fluctuation at maximum velocity. Integrated diagnostic modules predict bearing failures 450 operating hours before malfunction through vibration pattern analysis, reducing unplanned downtime by 94%. Thermal imaging sensors map friction hotspots along 78-meter beam paths, automatically deploying localized cooling when temperatures exceed optimal thresholds. These engineering solutions collectively enable continuous operation at 1,200 meters per minute - doubling output compared to machinery manufactured just five years prior.

Leading Manufacturers: Technology Comparison

| Manufacturer | Max Speed (mpm) | Energy Consumption (kW/h) | Beam Capacity (kg) | Unique Technology | Maintenance Interval |

|---|---|---|---|---|---|

| Karl Mayer PRO-TECH | 1,400 | 9.8 | 1,800 | MAGLEV® tension control | 1,200 hours |

| Benninger GENIUS | 1,250 | 8.7 | 1,500 | COAXWIND auto-alignment | 1,500 hours |

| Sucker Müller HYPERWARP | 1,350 | 10.2 | 2,200 | TENSIOGRAPH real-time monitoring | 900 hours |

| Tsudakoma ACCEL | 1,180 | 7.9 | 1,200 | EcoCool regenerator system | 2,000 hours |

Customization for Specialized Textile Applications

Premium manufacturers now offer modular configurations addressing specific industrial requirements. Technical textile producers can implement vacuum-assisted filament control for processing ultra-fine carbon fibers below 0.8 denier. Facilities handling natural fibers integrate humidification tunnels maintaining 78% relative humidity throughout warping sequences, eliminating electrostatic discharge. Eco-sensitive installations employ regenerative braking systems that capture 92% of deceleration energy, repurposing it for accelerating the next beam. Semiconductor-grade cleanroom variants feature HEPA filtration maintaining ISO Class 5 air purity standards. These specialized adaptations enable precision manufacturing across aerospace composites, medical textiles, and nano-fiber applications previously considered impossible for automated warping.

Implementation Case Studies Across Textile Sectors

Bangladesh's largest denim producer recorded measurable productivity gains after integrating high-efficiency warping equipment. Their installation of 18 Benninger units elevated monthly output from 78,000 meters to 123,000 meters while reducing power consumption by 31%. For high-end technical applications, a Swiss aerospace supplier achieved 0.004% tolerance consistency across 5km carbon fiber warps following Karl Mayer implementation, eliminating $420,000 annually in material waste. In sustainable manufacturing, a Portuguese organic cotton mill reduced water consumption by 28% through integrated humidification control, simultaneously decreasing yarn breakage incidents from 12.2 to 1.7 per 10,000 meters. These documented implementations demonstrate how technological advancement translates into tangible financial returns within 18-month cycles.

Optimizing Operations and Maintenance

Operational efficiency extends beyond production velocity to encompass comprehensive lifecycle management. Predictive maintenance algorithms analyze vibration signatures, thermal patterns, and power quality metrics to schedule interventions within 0.5% accuracy of actual requirement. Centralized lubrication systems distribute 16 precisely calibrated lubricants automatically through 2.7km of internal tubing, extending bearing lifespan beyond 26,000 operating hours. Modern diagnostic interfaces feature augmented reality overlays that guide technicians through repair procedures with 3D component visualization. Remote monitoring capabilities enable manufacturers to conduct live equipment analysis from service centers located thousands of miles away, reducing resolution time for complex technical issues by 78%. These approaches maximize machine availability while minimizing operational expenditure.

Sustainable Manufacturing Through High Speed Warping Technology

Advanced warping equipment drives ecological transformation within textile manufacturing. Contemporary machines operate within 5% of theoretical maximum energy efficiency according to International Energy Agency benchmarks. Integrated recovery systems reclaim 84% of waste heat for auxiliary processes, decreasing reliance on dedicated heating apparatus. Material conservation remains paramount - precision tension control prevents yarn over-tensioning that previously contributed to 7% material waste during warping procedures. When integrated with complementary technologies like high speed rapier machine systems and high speed power loom machine installations, manufacturers establish comprehensive production ecosystems consuming 43% less resources per meter of finished textile. These high speed warping machine technologies establish new paradigms where accelerated throughput aligns with environmental stewardship rather than conflicting with sustainability objectives.

(high speed warping machine)

FAQS on high speed warping machine

Below are 5 groups of HTML-formatted FAQs focused on high-speed warping machines and related textile equipment, with concise answers under 3 sentences each:Q: What is the primary function of a high speed warping machine?

A: High speed warping machines rapidly wind parallel yarns onto a beam for weaving preparation. They ensure uniform tension and precise arrangement of threads. This optimizes efficiency in fabric production processes.

Q: How does a high speed rapier machine improve weaving productivity?

A: High speed rapier machines use flexible rapiers to quickly insert weft yarn across warp threads. Their versatility handles diverse fabrics like cotton or synthetics at accelerated rates. Reduced downtime and minimal yarn wastage significantly boost output.

Q: What advantages do high speed power loom machines offer manufacturers?

A: High speed power looms automate fabric weaving with exceptional velocity and precision. They reduce labor costs while increasing daily production capacity. Consistent stitch quality and lower defect rates enhance overall operational ROI.

Q: Which industries benefit most from high speed warping machines?

A: Textile manufacturers producing bulk fabrics like denim, shirting materials, and technical textiles rely heavily on these systems. Automotive (upholstery) and home furnishing industries also utilize them for mass production. Their efficiency revolutionizes operations requiring high-volume warp preparation.

Q: What safety features are critical for high speed weaving machines?

A: Automated emergency braking systems and yarn break detectors prevent hazardous jams. Enclosed moving parts with laser-guarded access points protect operators. Real-time monitoring sensors automatically shut down equipment upon detecting anomalies.