Paragraph Outline:

- Fundamentals and critical features of section warping technology

- Technical advantages driving operational transformation

- Efficiency metrics and economic impact analysis

- Global manufacturer capability comparison

- Customization frameworks for specialized applications

- Industry-specific implementation case studies

- Strategic perspectives for textile manufacturing evolution

(section warping machine)

Understanding Modern Section Warping Machine Fundamentals

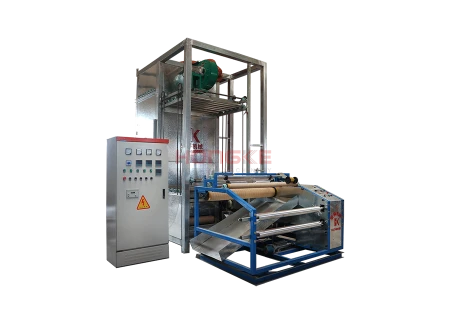

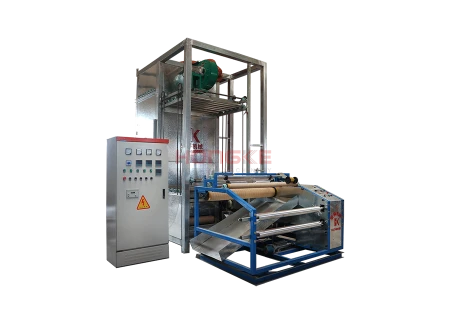

Contemporary section warping machine

s represent the cornerstone of high-volume textile production, engineered to transfer yarns from cones to beams with micrometer precision. Their primary function resolves around creating consistent, defect-free warp sections essential for shuttleless looms. Unlike traditional beam warping, this technology maintains precise yarn alignment across thousands of threads while accommodating diverse materials - from delicate silk filaments to abrasive technical fibers. Critical components include electronically synchronized creel systems, laser-guided tension controllers, and programmable section profiling. The most advanced models incorporate automatic yarn-break detection sensors that pause operation within 0.8 seconds, reducing material waste by up to 29% compared to mechanical systems.

Operational Advantages Transforming Textile Production

Modern warping machine manufacturers have eliminated three historical constraints: speed limitations, pattern complexity barriers, and changeover downtime. Advanced servo motors now enable winding speeds reaching 1,200 meters/minute while maintaining tension variation below ±0.2 cN. This technological leap reduces energy consumption per meter by approximately 35% compared to decade-old equipment. Pattern versatility represents another breakthrough, with dual-processor controls executing up to 100 complex patterns without manual intervention. Furthermore, automated beam-change systems achieve configuration swaps in under 8 minutes - a 78% reduction versus mechanical counterparts. These collective advancements enable textile mills to handle smaller, specialized orders profitably while meeting demanding fast-fashion timelines.

Quantifiable Efficiency Metrics and Industry Impact

Operational data substantiates section warping machine superiority across three critical metrics: waste reduction, maintenance requirements, and production scalability. Mills utilizing current-generation equipment report:

- Material savings averaging 18-22% through precision tensioning systems

- Preventative maintenance intervals extended to 400 operating hours versus legacy 150-hour requirements

- 15% higher throughput density on beams, directly increasing loom productivity

This efficiency translates to measurable economic impact: a medium-scale facility processing 50 tons monthly achieves ROI within 18 months post-upgrade. Automation compatibility proves equally significant, with Industry 4.0-equipped models integrating directly into MES systems to provide real-time quality analytics across 200+ parameters.

Global Manufacturer Technology Comparison

| Manufacturer | Max Speed (m/min) | Tension Control | Beam Capacity | Automation Grade |

|---|---|---|---|---|

| Karl Mayer | 1,200 | ±0.15 cN | 40 tons | Industry 4.0 |

| Benninger | 1,050 | ±0.18 cN | 35 tons | PLC Integrated |

| Tsudakoma | 950 | ±0.25 cN | 28 tons | Semi-Automated |

Leading warping machine manufacturers differentiate through proprietary technologies like Karl Mayer's AI-based pattern prediction systems and Benninger's hydraulic-less tension stabilization. These innovations minimize mechanical wear while ensuring consistent quality across lengthy production cycles.

Application-Tailored Engineering Solutions

Progressive manufacturers now offer modular configuration platforms adapting core warping technology to niche applications. Technical textile producers leverage reinforced beam structures supporting 60-ton carbon fiber processing, while fine-yarn specialists utilize electrostatic elimination systems for microfiber handling. Customization options extend beyond hardware to encompass:

- Material-specific creel designs minimizing fiber abrasion

- Moisture-controlled environments for hygroscopic yarns

- API-integrated production planning software

A prominent Pakistani bedding manufacturer recently commissioned a section warping machine with dual tension zones enabling simultaneous processing of dissimilar cotton blends. This configuration eliminated previously necessary secondary processing, reducing labor by 40% and increasing daily output by 28 metric tons.

Cross-Industry Deployment Case Studies

The versatility of contemporary warping equipment manifests across sectors. In automotive textiles, a German supplier reduced airbag fabric defects by 97% after installing tension-monitored warpers with automatic compensation. Home furnishing leader Indo Count achieved 20% higher loom efficiency by implementing beam uniformity controls critical for jacquard patterns. Technical fabric innovators face particular advantages: Kermel's aramid production saw energy consumption decrease 31% using targeted heat-recovery systems in their warping process. These implementations validate that proper section warping machine application generates competitive advantages regardless of segment specialization.

Strategic Outlook for Textile Manufacturing Evolution

Next-generation warping technology development focuses on three transformative frontiers: energy autonomy through kinetic recovery systems, self-optimizing AI controls requiring zero technician intervention, and hyper-compact modular designs enabling urban micro-factories. Forward-looking manufacturers already piloting closed-loop operations report 85% reduced wastewater generation - critical compliance advancement as global regulations tighten. These innovations position warping machinery as both productivity engines and sustainability accelerators. Mills adopting such integrated solutions gain not just operational superiority but strategic resilience amid volatile raw material markets. The progression confirms section warping machine centrality in redefining textile manufacturing paradigms.

(section warping machine)

FAQS on section warping machine

Q: What is a section warping machine used for in textile manufacturing?

A: A section warping machine prepares yarns by winding them onto a beam in sections, enabling efficient pattern creation and reducing yarn breakage during weaving. It is essential for producing complex fabric designs and ensuring consistent tension. This process streamlines high-volume textile production.

Q: How to choose a reliable warping machine manufacturer?

A: Prioritize manufacturers with proven expertise, certifications like ISO standards, and customizable solutions. Evaluate their after-sales support, warranty terms, and client testimonials. Opt for providers offering advanced features like automated tension control.

Q: What are the advantages of section warping over beam warping?

A: Section warping allows precise pattern alignment and reduces yarn waste, ideal for intricate designs. It supports smaller batch production with flexibility in color or yarn changes. Beam warping, however, is faster for single-pattern, large-scale runs.

Q: How to maintain a warping machine in textile production?

A: Regularly clean and lubricate mechanical parts to prevent dust buildup. Calibrate tension sensors and inspect electronic components for wear. Schedule professional servicing annually to ensure optimal performance and longevity.

Q: What technical specifications matter when buying a warping machine?

A: Key specs include maximum beam capacity, warp length precision (e.g., ±0.1%), and speed (meters/minute). Check compatibility with yarn types (cotton, synthetics) and automation levels, such as IoT integration for real-time monitoring.